Optical pickup apparatus

a technology of optical pickup and optical head, which is applied in the manufacture of optical head, data recording, instruments, etc., can solve the problems of large number of construction parts and respective parts, the effect of avoiding the decrease of s/n, high efficiency and small siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

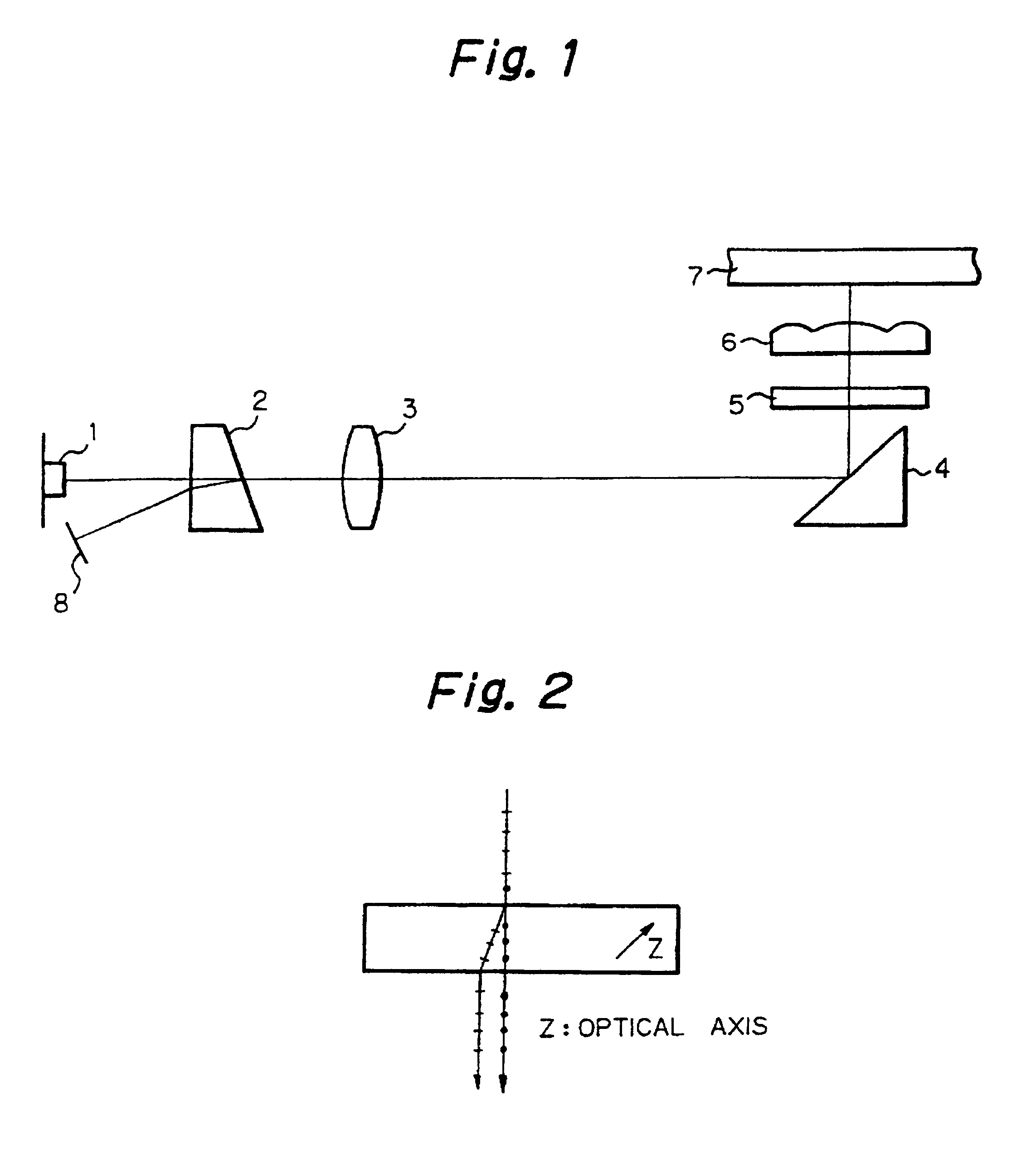

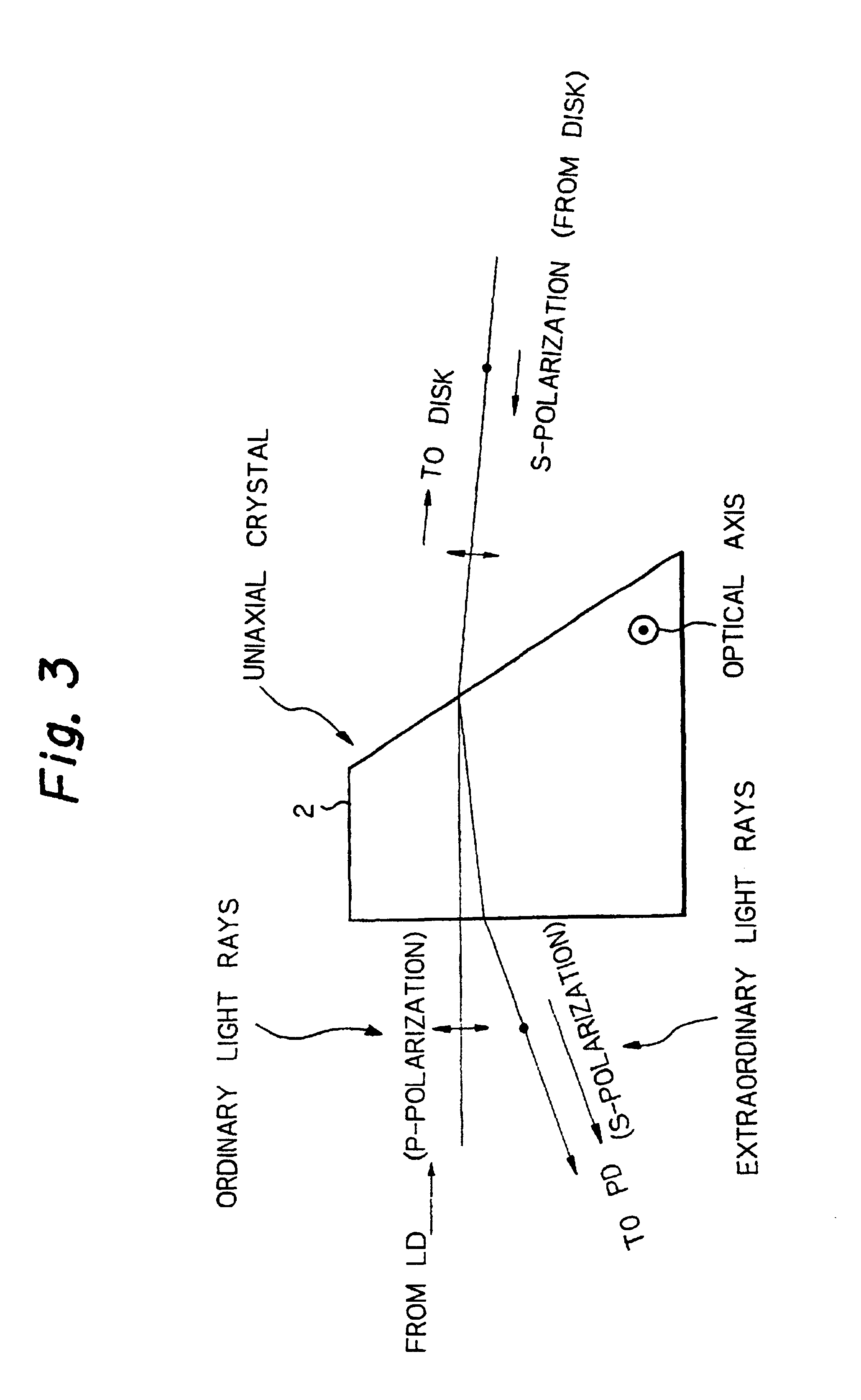

[0146]FIG. 1 is a construction diagram for explaining the optical pickup apparatus according to the present invention. In FIG. 1, the reference numeral 1 represents a semiconductor laser (LD), 2 a birefringent crystal, 3 a coupling lens, 4 a polarizing mirror, 5 a quarter-wave (λ / 4) plate, 6 an objective lens, 7 an optical recording medium, and 8 a light-receiving element (PD).

[0147]The linearly polarized divergent light rays emitted from the semiconductor laser 1 pass through the complex refraction crystal 2, and are converted to the parallel light rays by the coupling lens 3, and further are deflected by the deflecting mirror 4. The light rays deflected by the deflecting mirror 4 are converted to the circularly-polarized light rays by the quarter-wave (λ / 4) plate 5 and focused on the recording surface of the optical recording medium 7 by the objective lens 6. The light rays flux reflected on the recording surface are made parallel again by the objective lens 6 and the same are con...

second embodiment

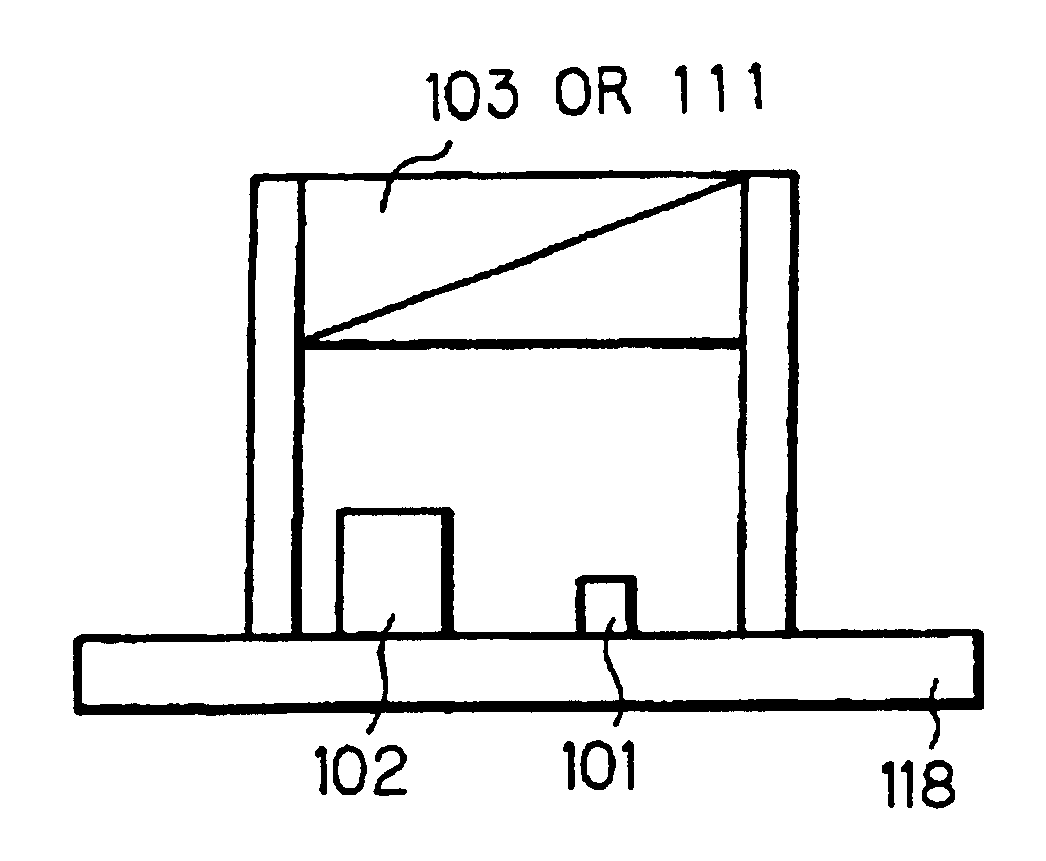

[0155]FIGS. 5 and 6 are construction diagrams showing the other embodiment (second embodiment) of the optical pickup apparatus according to the present invention. In FIG. 5, the reference numeral 11 represent a semiconductor laser (LD) package, 12 an LD chip, 13 a light-receiving element (PD), and 14 a birefringent crystal.

[0156]The PD 13 is accommodated in the LD package 11. The separation distance of the LD chip 12 and the PD 13 can be determined from the parameters; the refractive index and the thickness of the complex refraction crystal, and the angle of the incident light rays. For instance, in case that the parallel plain plate made of the birefringent material of the thickness d as shown in FIG. 6 is disposed slantedly by θ for the optical axis, the separation distance can be expressed as mentioned below.

[0157]Assuming that the incident angle to the birefringent material is α, the refractive index of the refraction line of the ordinary light rays in the birefringent material ...

third embodiment

[0160]FIG. 7 is a construction diagram for explaining the other embodiment (third embodiment) of the optical pickup apparatus according to the present invention. In FIG. 7, the reference numeral represents a birefringent crystal, and same reference numeral is attached to the portion executing the same function as that of the optical pickup apparatus shown in FIG. 5. The birefringent crystal 15 is employed as the window member of the LD package 11 for both of the LD chip and the PD 13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compass direction angle | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com