Patents

Literature

169results about How to "Input power uninterrupted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torque convertor

PendingCN101012870ASimple structureLow costToothed gearingsFluid gearingsGear wheelArchitectural engineering

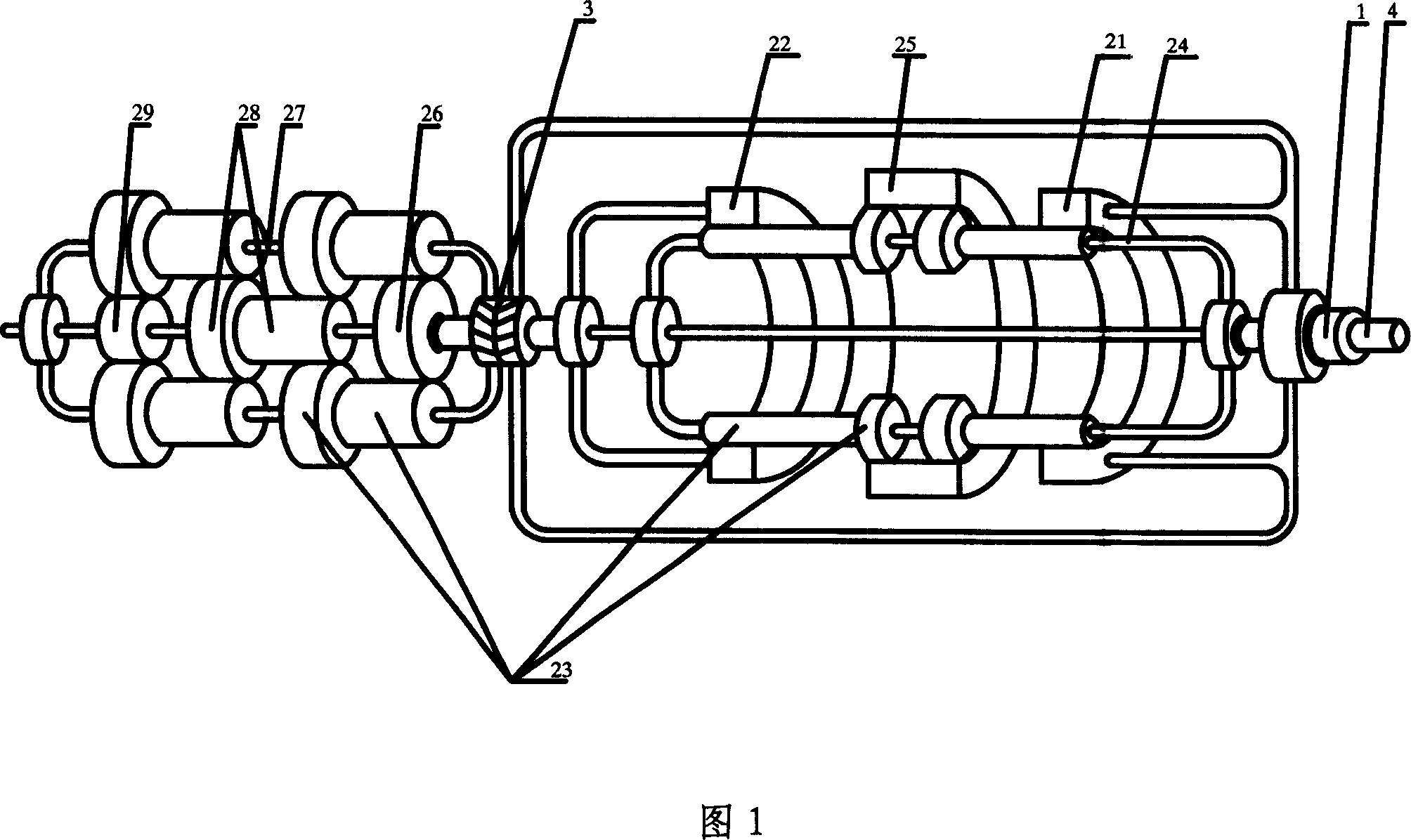

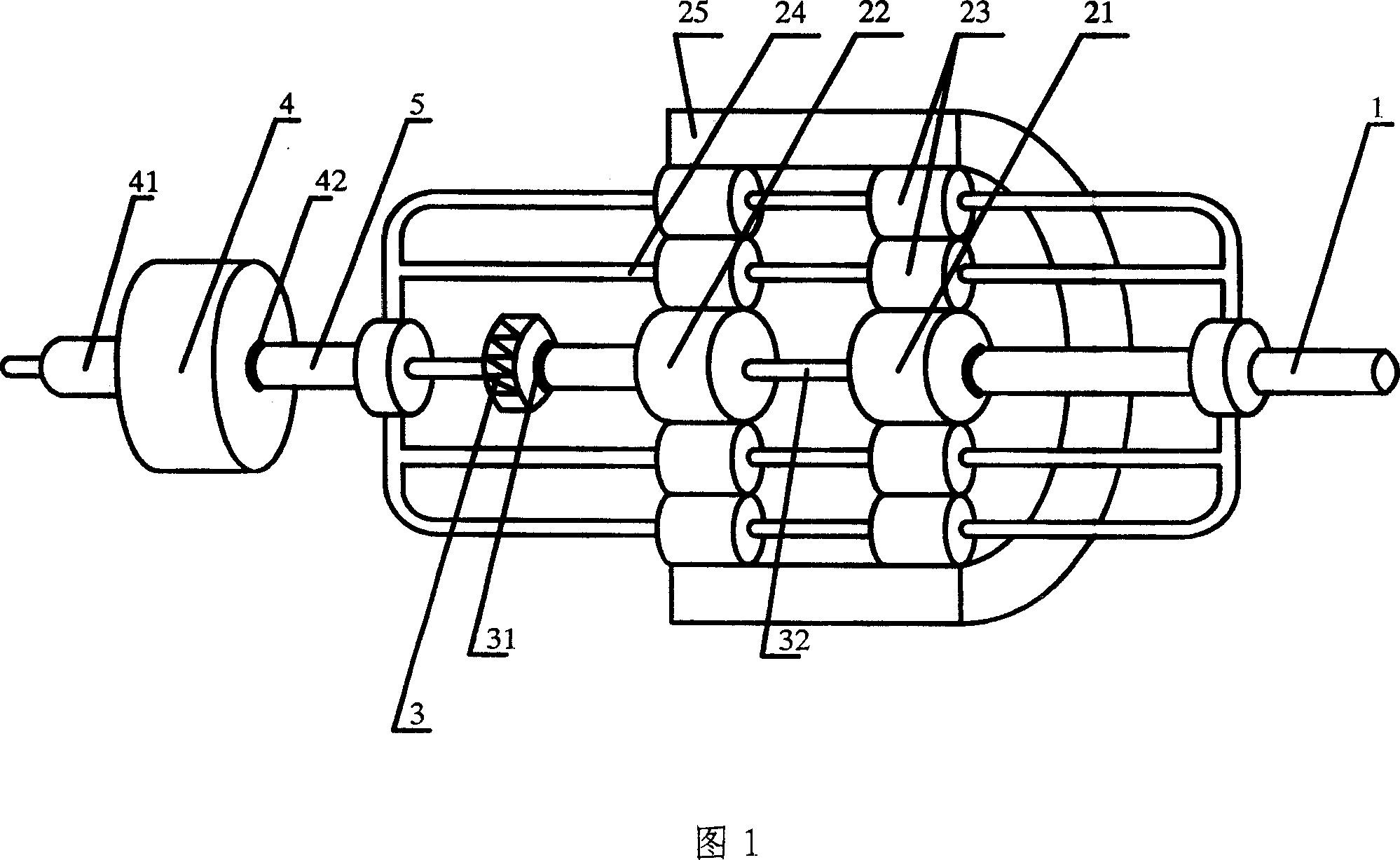

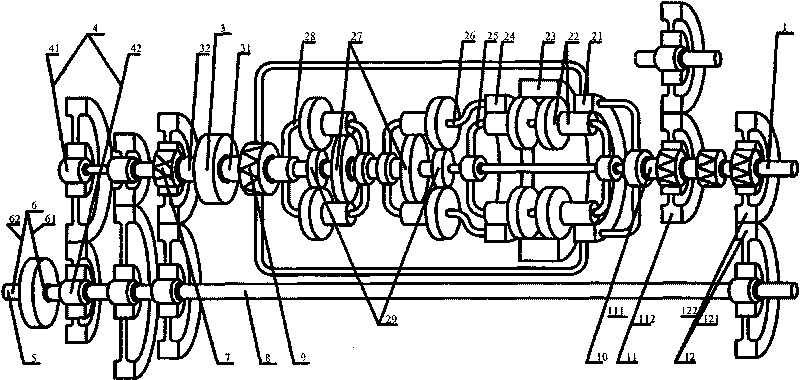

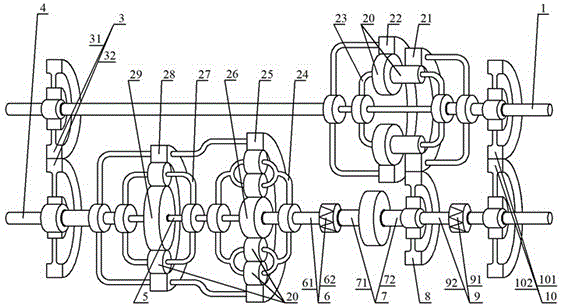

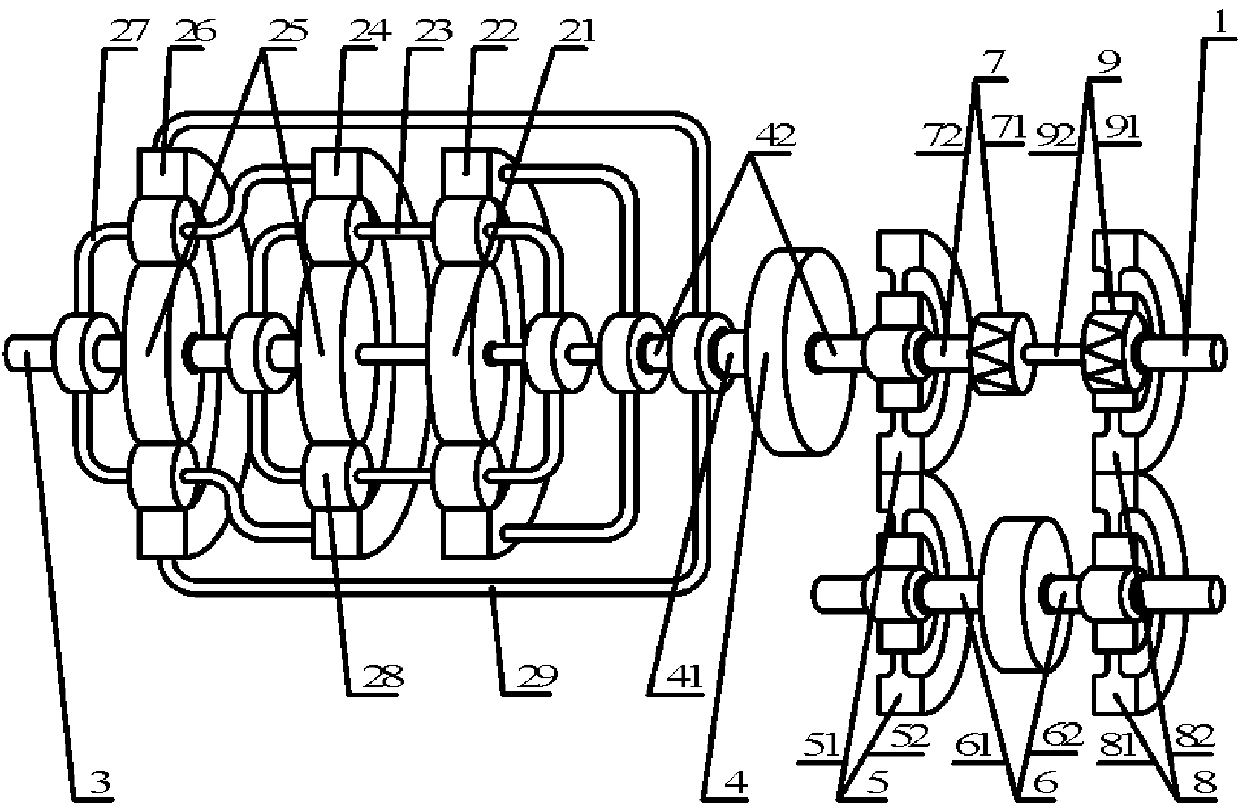

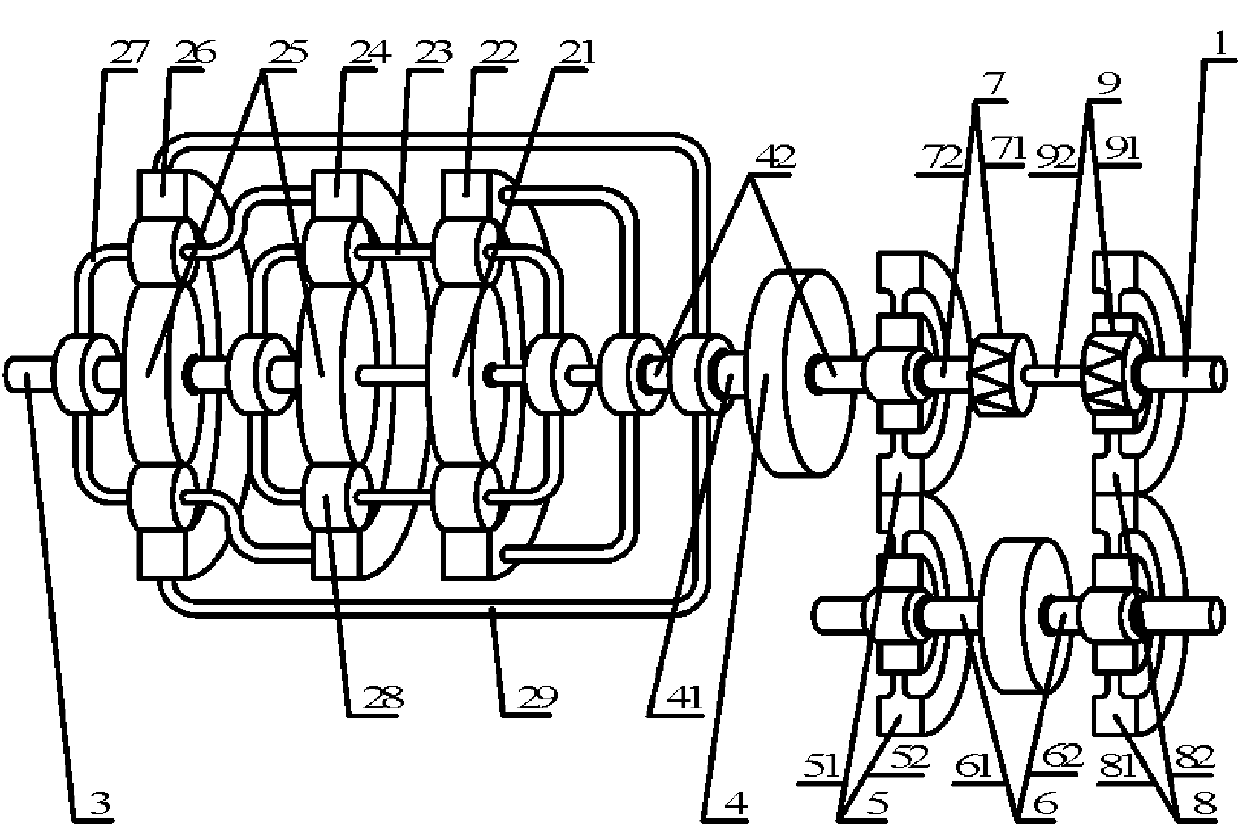

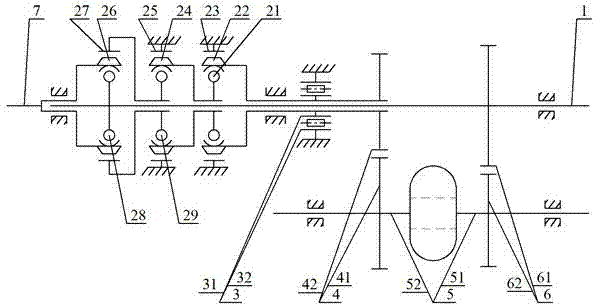

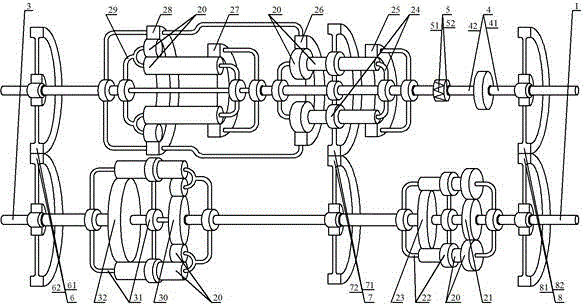

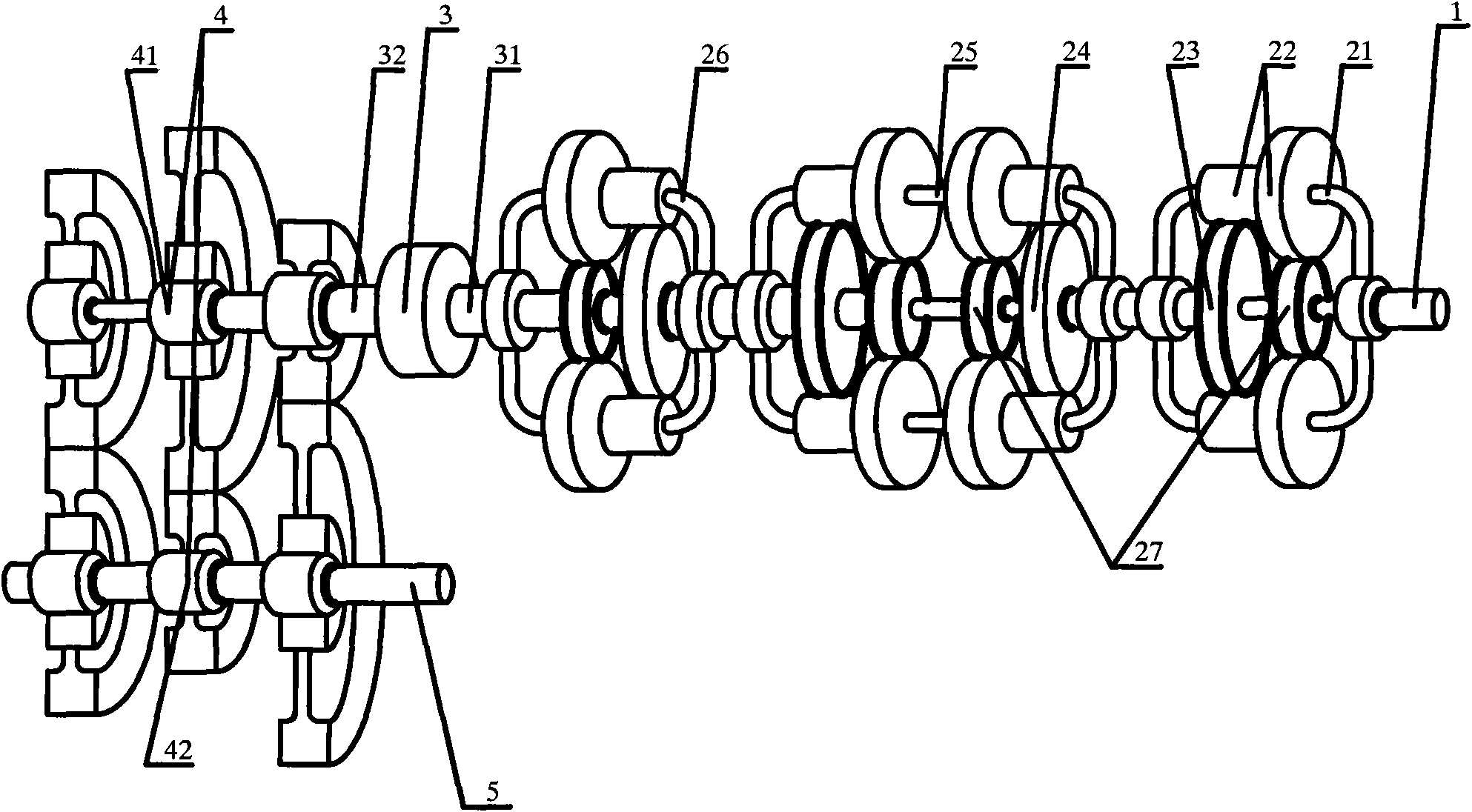

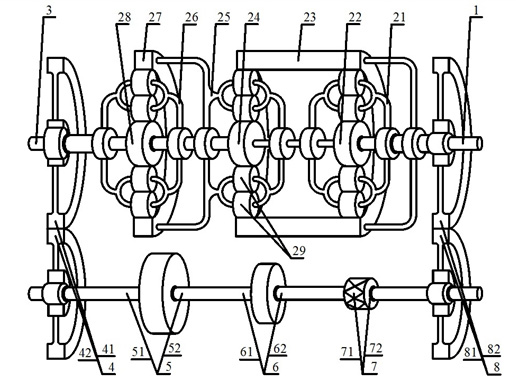

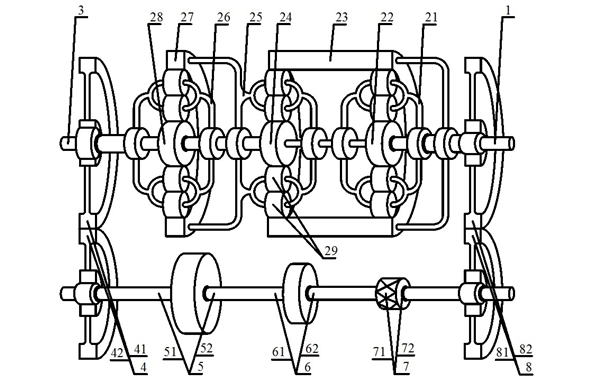

The invention provides a torque changer for prolong the service lives of engine and transmitter. The invention comprises an input axle 1, a connector 3, and an output axle 4. The input axle 1 and the output axle 4 are arranged with an input tooth ring 21, an output tooth ring 22, a planet gear 23, a public output planet support 24, a connecting tooth ring 25, a large gear 26, a public planet support 27, a connecting gear 28, and a small gear 29 between them. The input tooth ring 21 is connected to the input axle 1, and connected to the public output planet support 24 and the connecting tooth ring 25 via the planet gear 23. The connecting tooth ring 25 is connected to the output tooth ring 22 and the public output planet support 24 via the planet gear 23. The output tooth ring 22 is connected to the large gear 26. The large gea3 26 is connected to the public planet support 27 and the connecting gear 28 via the planet gear 23. The connecting gear 28 via the planet gear 23 is connected to the public planet support 27 and the small gear 29. The small gear 29 is connected to the external elements. The public planet support 27 is connected to the input tooth ring 21 via the connector 3. The public output planet support 24 is connected to the output axle 4.

Owner:吴志强

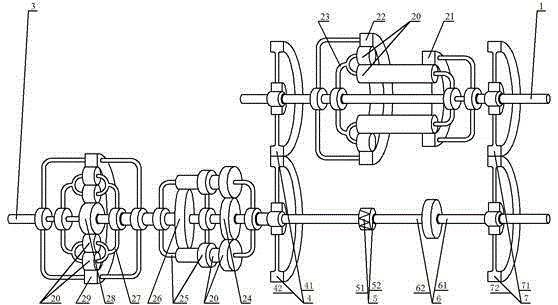

Stepless speed variator

InactiveCN101235877ASimple structureLow manufacturing costToothed gearingsFluid gearingsClutchVariator

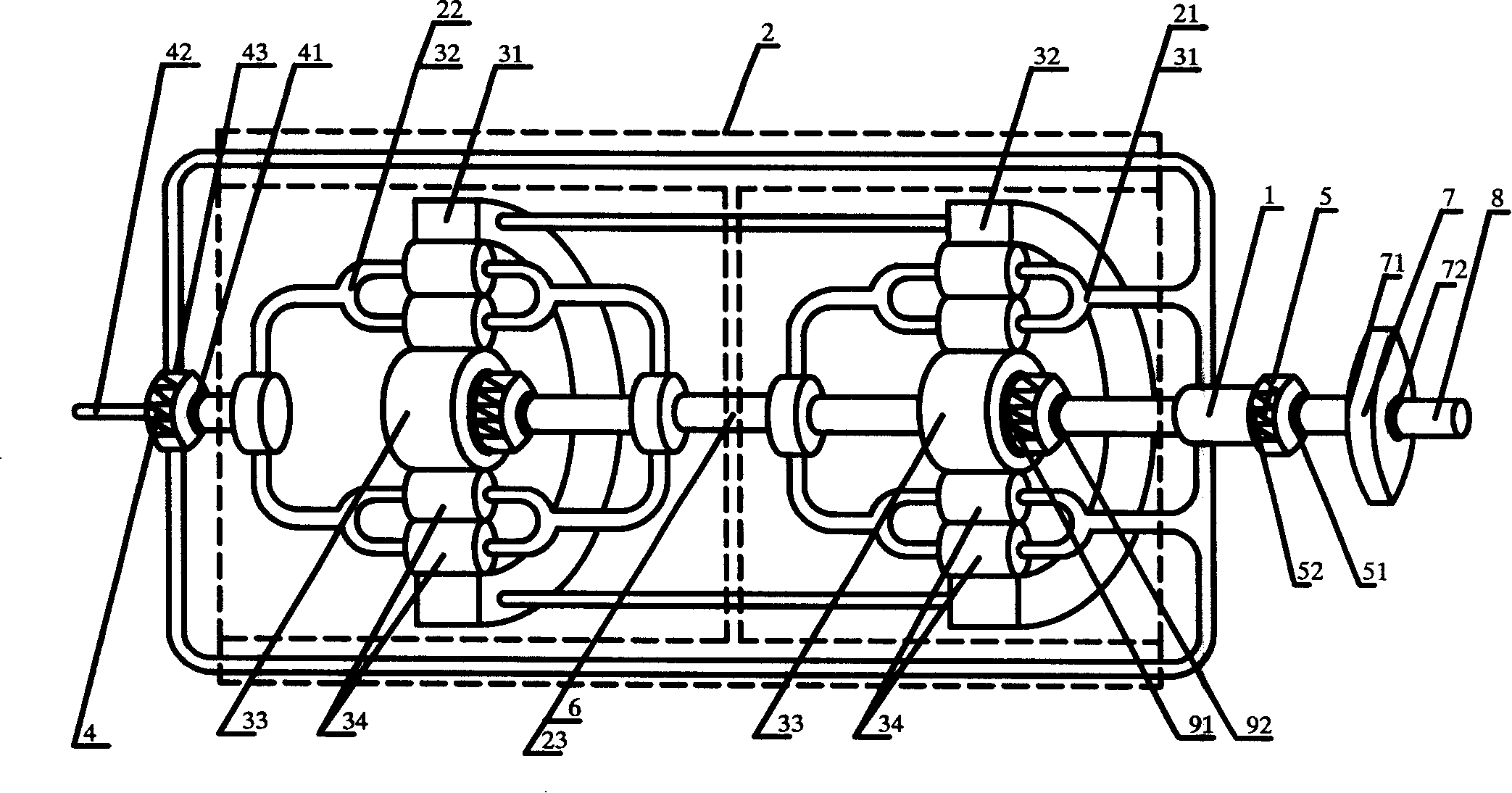

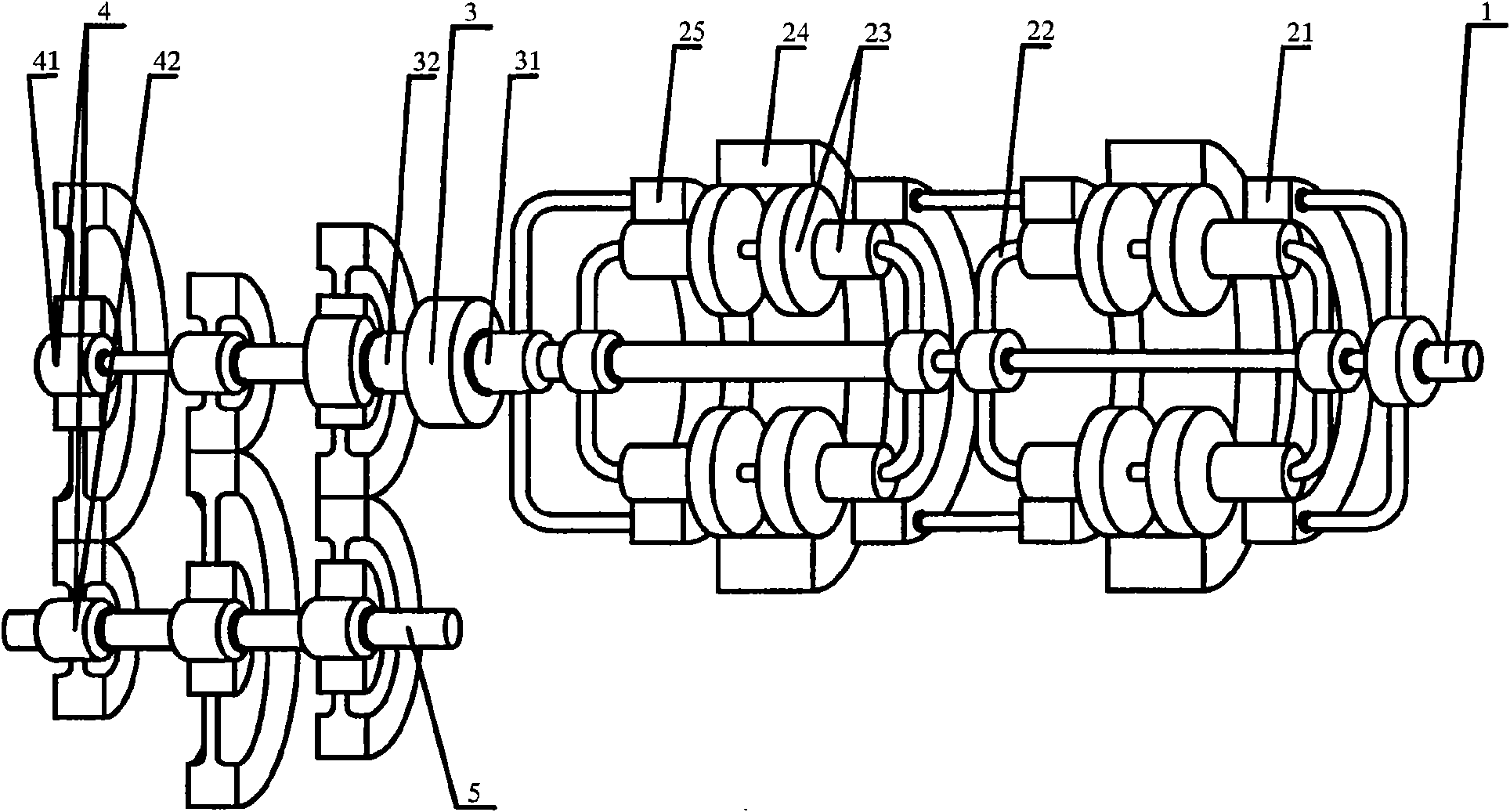

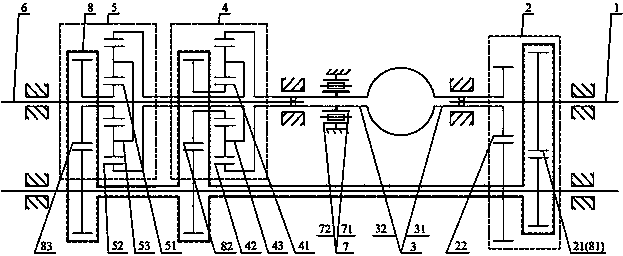

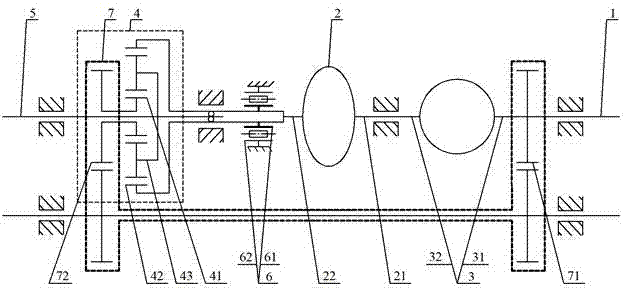

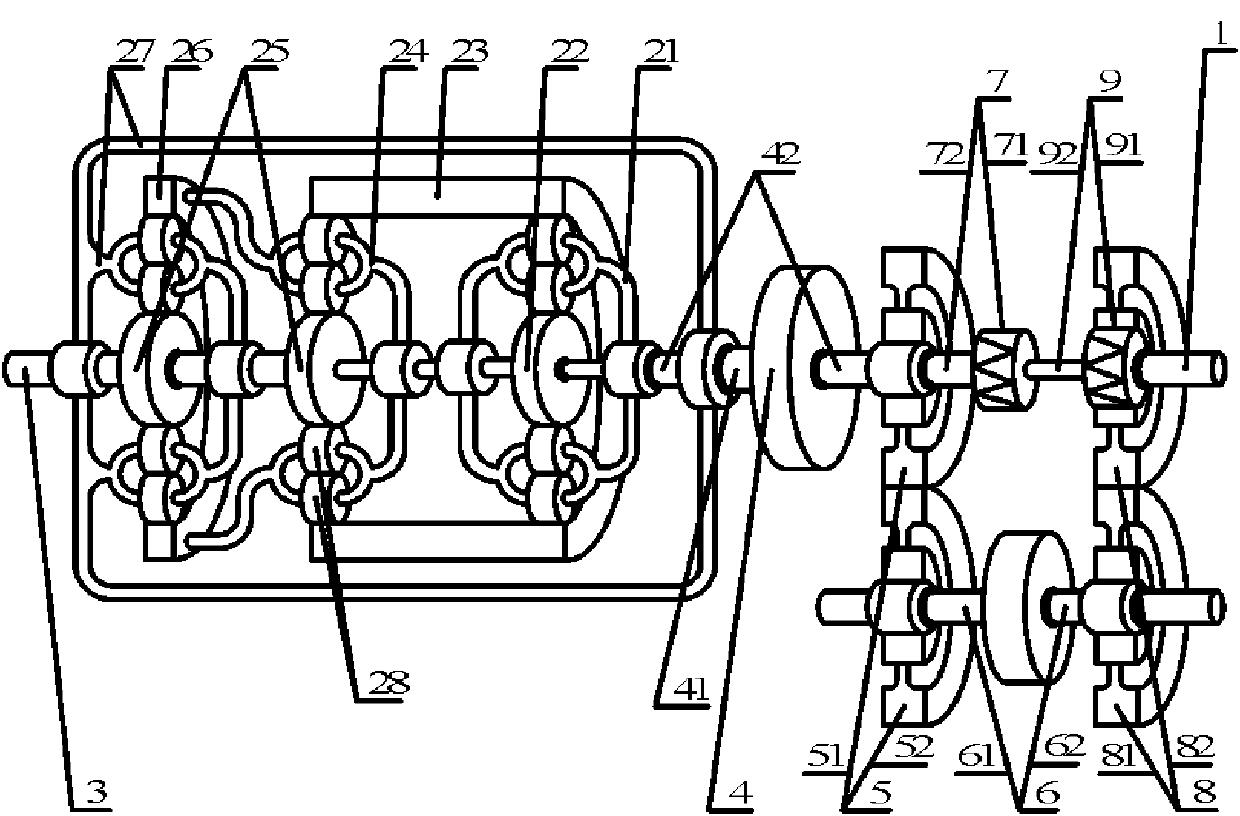

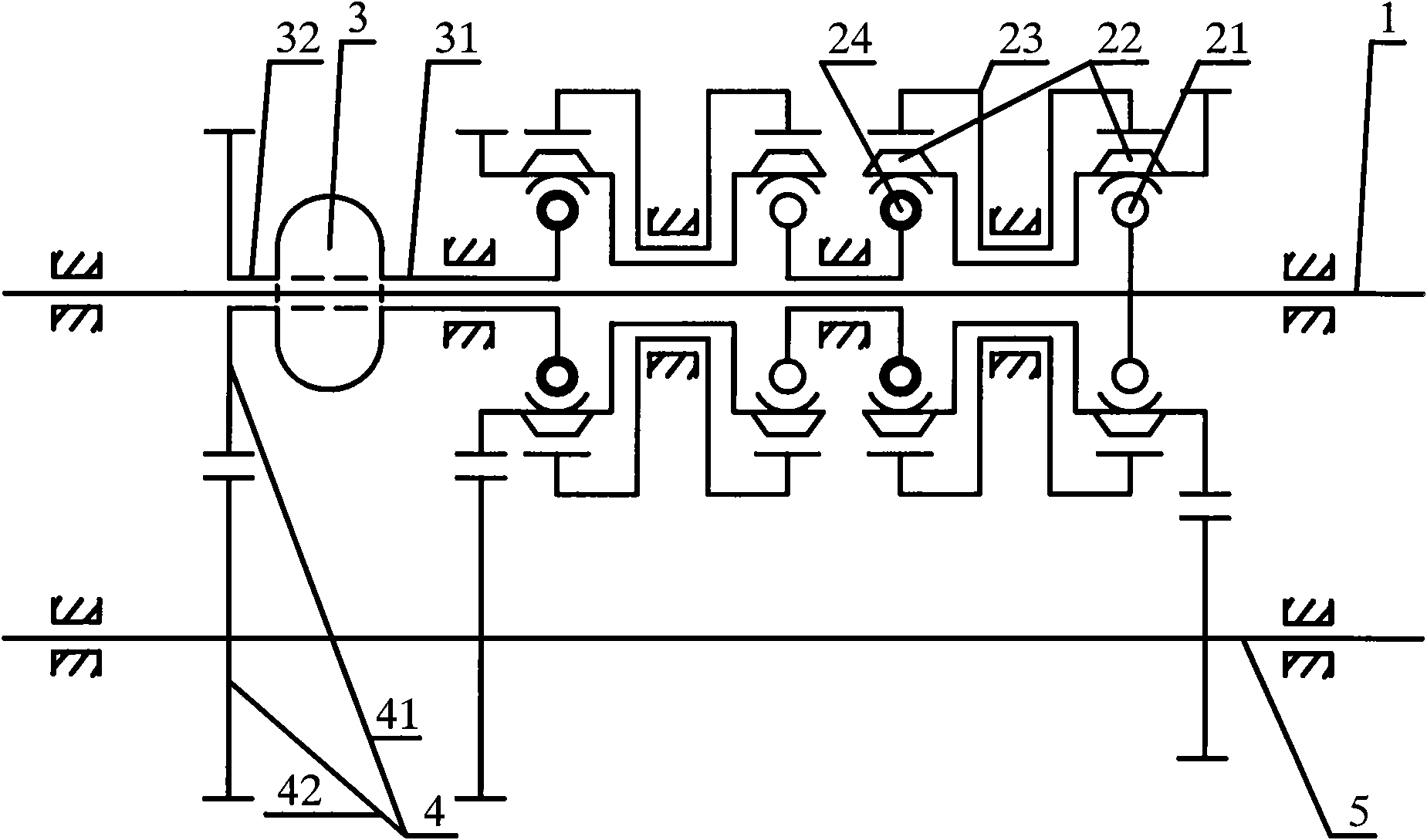

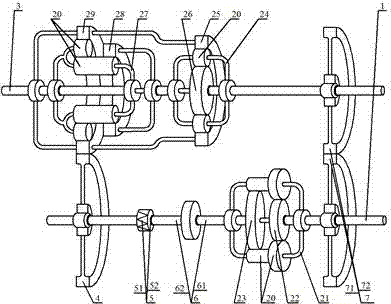

The invention provides a stepless transmission, which aims at providing a stepless transmission which prolongs the service life of the motor and the actuating system, has simple structure, convenient operation, low cost and is energy saving and highly efficient. The main points of the technical scheme is that the invention includes an input shaft, a coupler, a one-way clutch, a neutral and reverse mechanism and an output shaft, wherein an output end 52 of the one-way clutch 5 is connected with the output shaft 1, an output end 72 of the neutral and reverse mechanism 7 is connected with an output shaft 8, a moment converting unit 2 composed of a planetary row 3 and a public output shaft 6 which are sequentially collected and an one-way element 9 is arranged between the output shaft 1 and the output shaft 8, an input end of the moment converting unit 2 is connected with an input shaft 1, an output end 22 is connected with a coupler 4, an output end 44 of the coupler is connected with a plurality of elements except for elements of the stepless transmission, one end of a public output end 23 of the moment converting unit 2 is connected with an input end 71 of the neutral and reverse mechanism 7, and the other end is connected with an input end 51 of the one-way clutch 5.

Owner:吴志强

Hydraulic pump and hydraulic motor

The invention provides a hydraulic pump and a hydraulic motor, for prolonging the service lives of engine and transmitter, with simple structure and low cost. The invention comprises an input axle, a connector, a hydraulic pump, a hydraulic motor, and an output axle, wherein, the input axle and the output axle are arranged with an input outer mesh gear, an output outer mesh gear, a planet gear, a public planet support, and a connecting inner mesh tooth ring between them. The input outer mesh tooth ring is connected to the input axle, and connected to the connecting inner mesh tooth ring via the planet gear of public planet support. The connecting inner mesh tooth ring via another planet gear of public planet support is connected to the output outer mesh gear connected to the input of the connector. The output of connector is connected to the input inner mesh tooth ring and the inputs of hydraulic motor and hydraulic pump. The outputs of hydraulic motor and hydraulic pump and the public planet support are respectively connected to the output axle.

Owner:吴志强

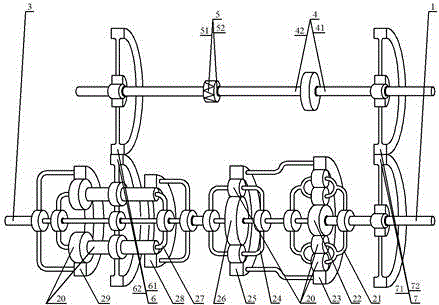

Composite inner cone output planetary cone type stepless variable speed unit

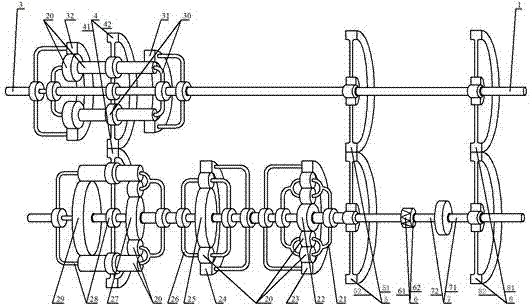

InactiveCN101598198AImprove power efficiencyImprove transmission efficiencyToothed gearingsEngineeringControl theory

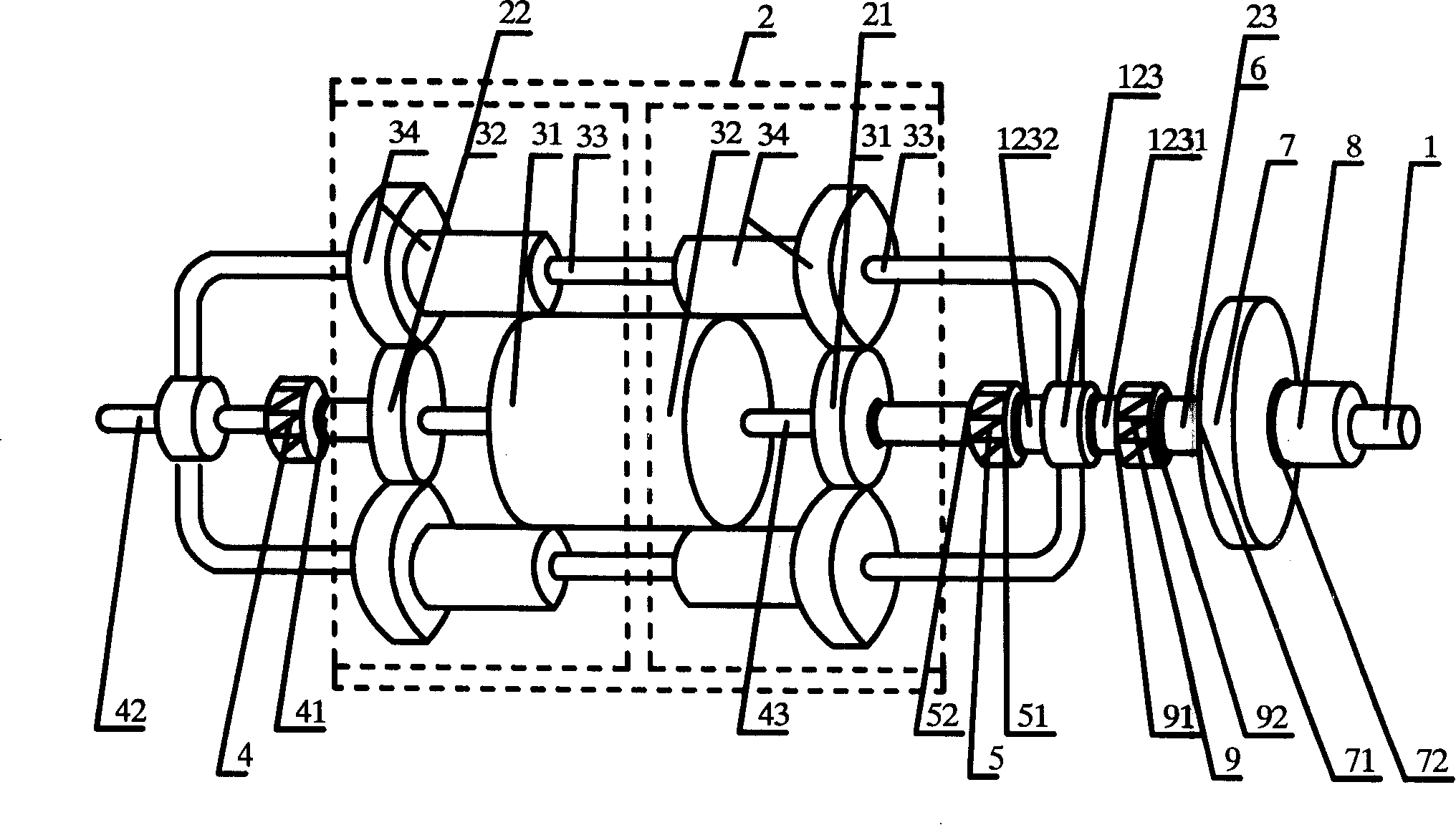

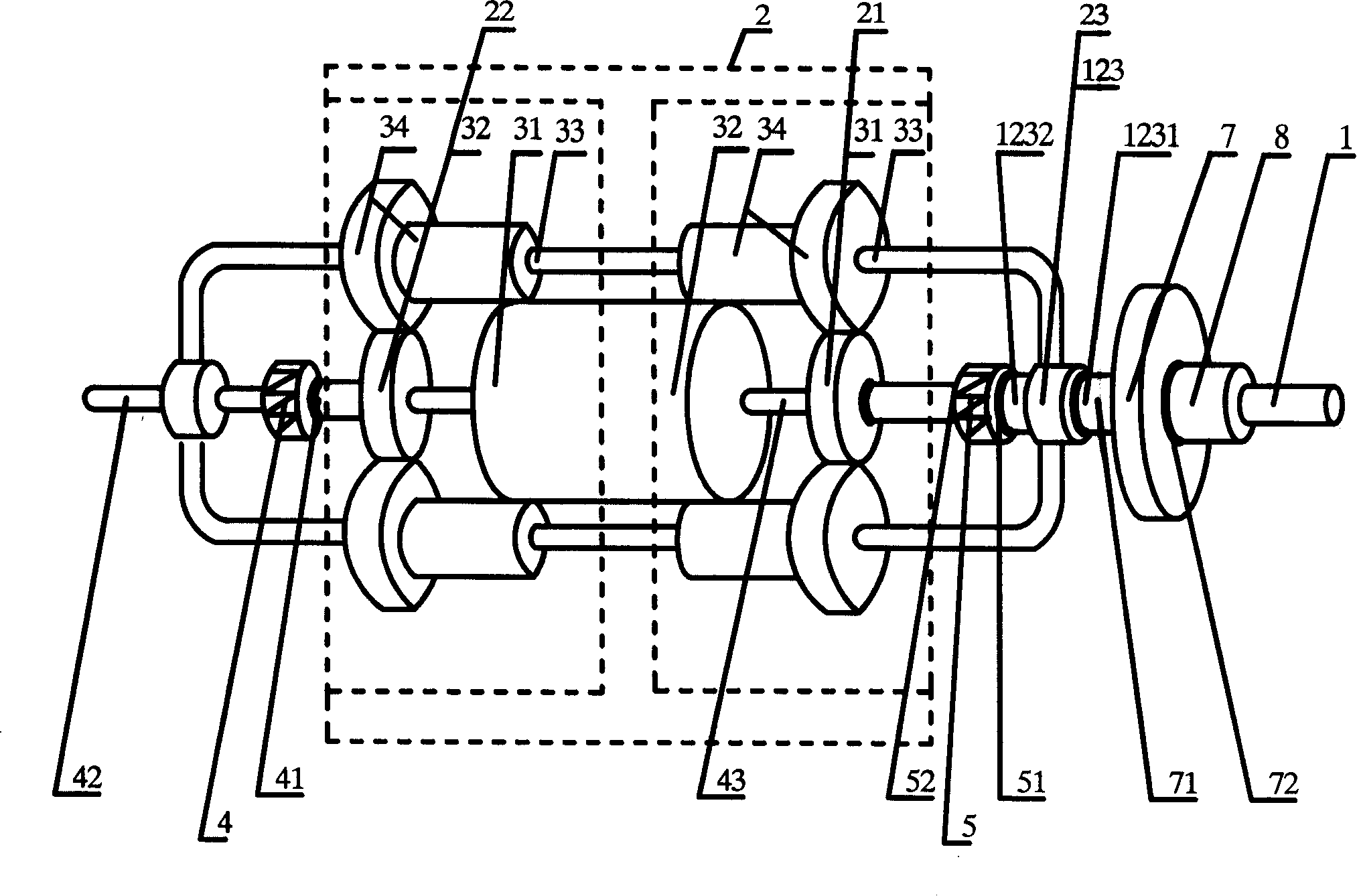

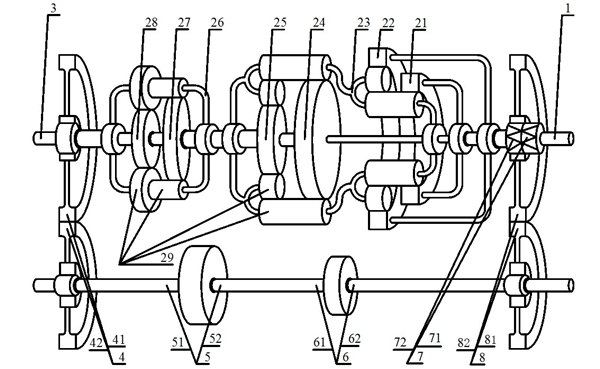

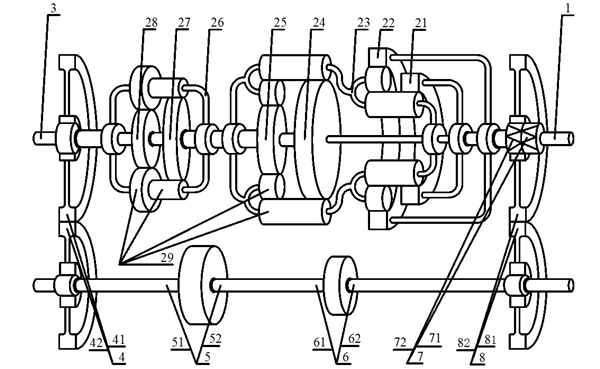

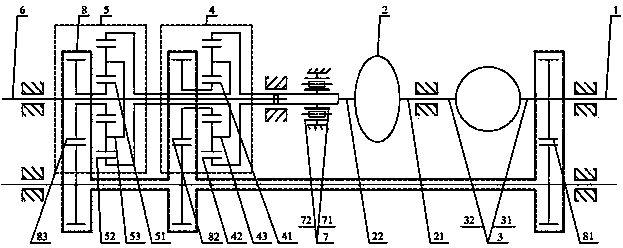

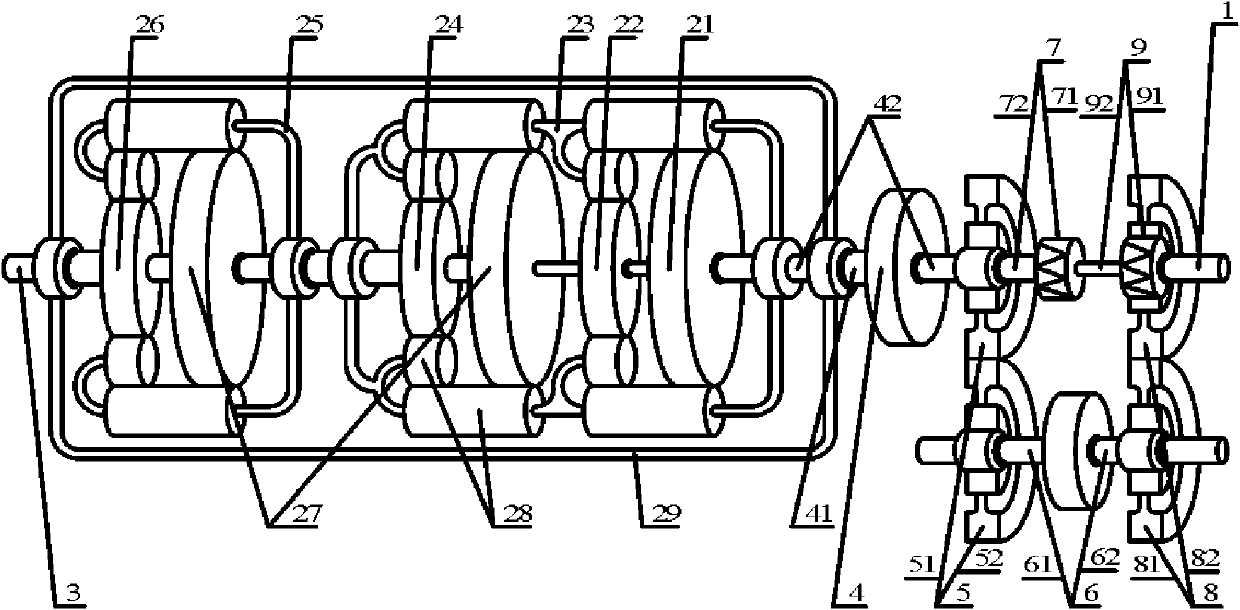

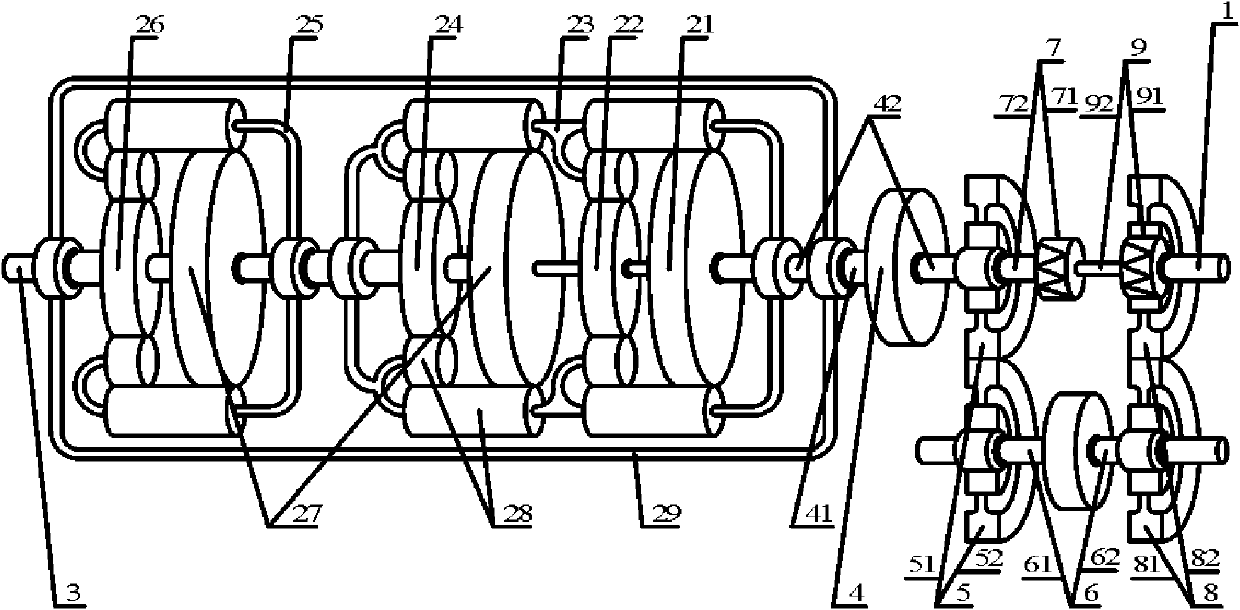

The invention provides a composite inner cone output planetary cone type stepless variable speed unit which has the technical scheme that a first input small gear ring 21 is connected with an input shaft 1; a first output planet carrier 22 is connected with the matched first input small gear ring 21, a first connecting big gear ring 24 and a first output small gear ring 25 by two groups of planetary gears 23 on the first output planet carrier 22; a second output planet carrier 22 is connected with a matched second input small gear ring 21, a second connecting big gear ring 24 and a second output small gear ring 25 by two groups of planetary gears 23 on the second output planet carrier 22; a second output small gear ring 25 is connected with the input end 31 of an inner cone output planetary cone type stepless variable speed unit 3; and the output end 32 of the inner cone output planetary cone type stepless variable speed unit 3 and all output planet carriers 22 are connected with input gears 41 of respectively matched gear pairs 4.

Owner:吴志强

Variable-speed device

The invention provides a stepless speed changer, which can prolong service life of engine and drive system, and has simple structure, operation and control convenience, low cost and high energy-saving efficiency. And the key points of its technical solution: it comprises input shaft, controllable moment apparatus, empty reverse gear mechanism, clutch, and output shaft, where there are several moment increasing units composed of planetary gear sets connected in turn, where each moment increasing unit comprises input component, output component, common output component, and planetary gear, the input component of the first moment increasing unit is connected with the input shaft and the common output component is connected to the output end of the controllable moment apparatus and then connected to the input end of the empty reverse gear mechanism, and the output unit of the last moment increasing unit is connected with the input end of the controllable moment apparatus.

Owner:吴志强

Composite box grind type hydraulic coupler

InactiveCN102312938AImprove power efficiencyImprove transmission efficiencyRotary clutchesFluid gearingsEngineeringControl theory

The invention provides a composite box grind type hydraulic coupler. The key points of the technical scheme are that: an input gear ring 21 is connected with an input shaft 1; a connecting planet carrier 23 is connected with the input gear ring 21, an input large gear ring 22, an output large gear 24 and an output gear 25; the output large gear 24 is connected with an output small gear 28 and an output shaft 3; the output gear 25 is connected with an input gear 27; an output planet carrier 26 is connected with the input gear 27 and the output small gear 28 and is connected with an input gear pair 4; the input gear pair 4 is connected with a speed change mechanism 5; the speed change mechanism 5 is connected with a box grind type hydraulic coupler 6; the box grind type hydraulic coupler 6 is connected with an output gear pair 8; and the output gear pair 8 is connected with a fixed one-way clutch 7 and the input large gear ring 22.

Owner:吴志强

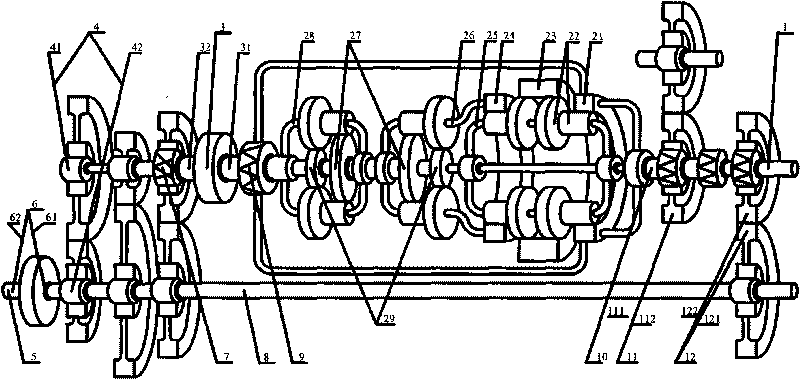

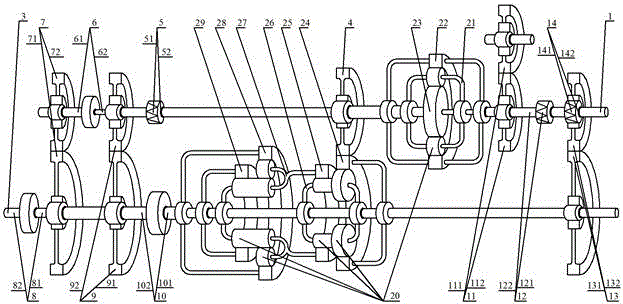

Simultaneous multi-gear meshing transmission of composite hydraulic torque converter

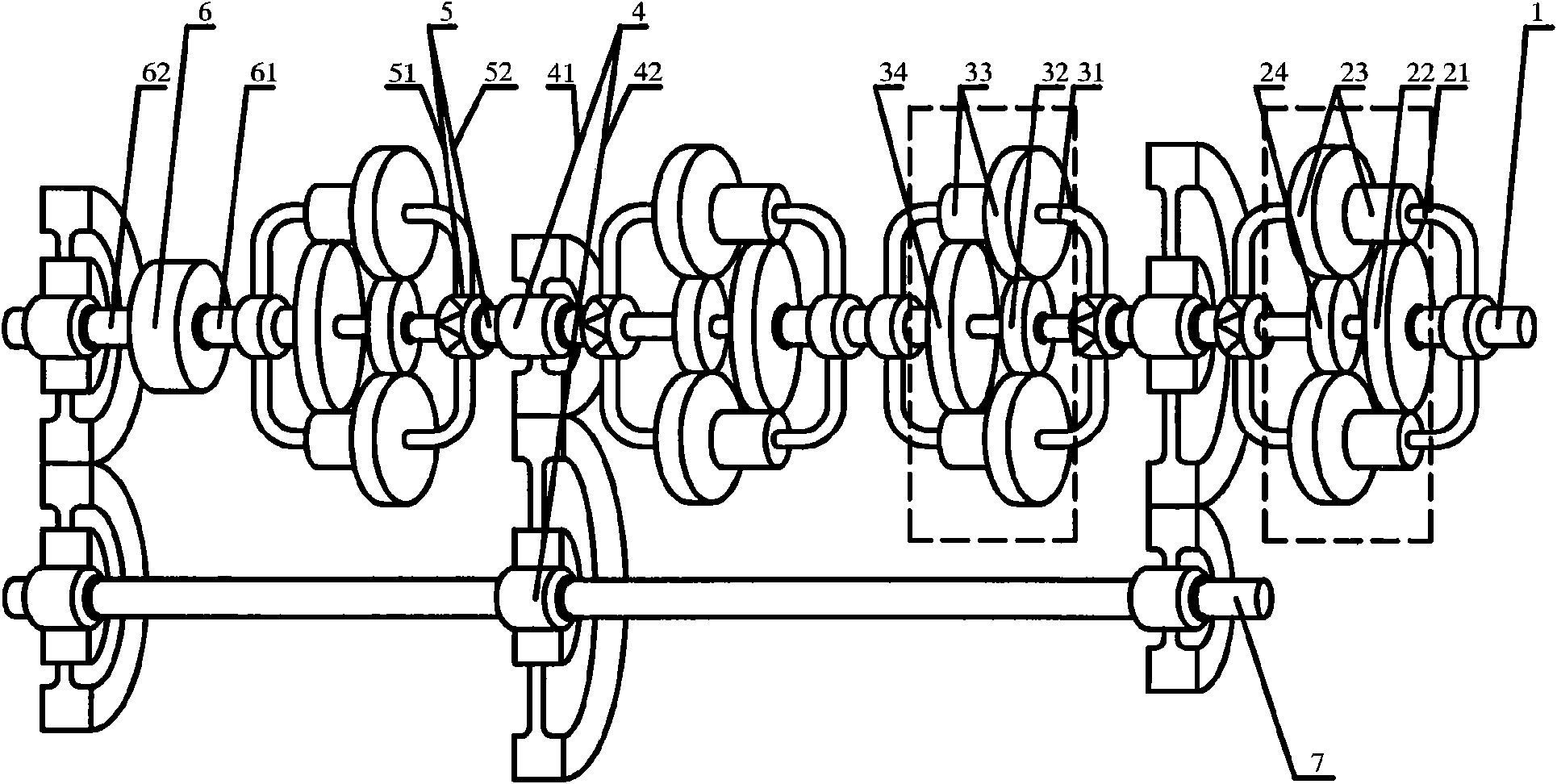

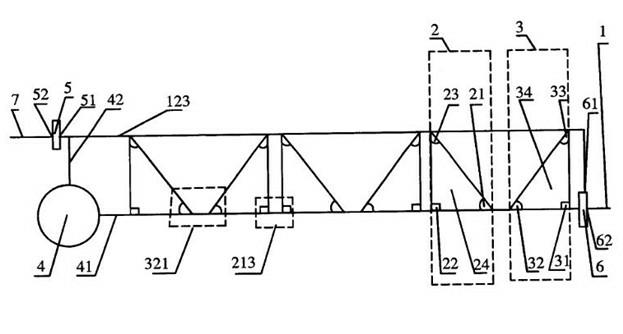

InactiveCN103148181AAvoid physical laborSimple structureToothed gearingsFluid gearingsControl theoryTorque converter

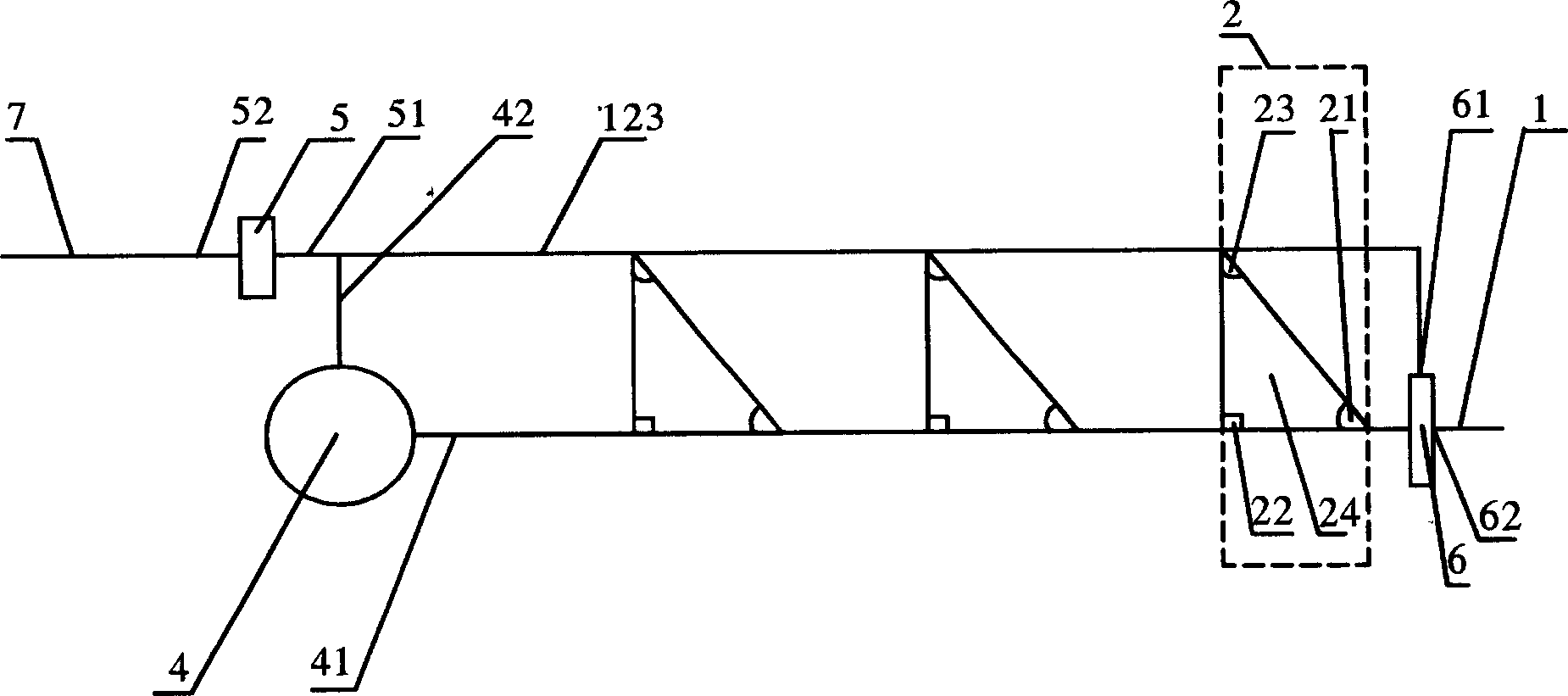

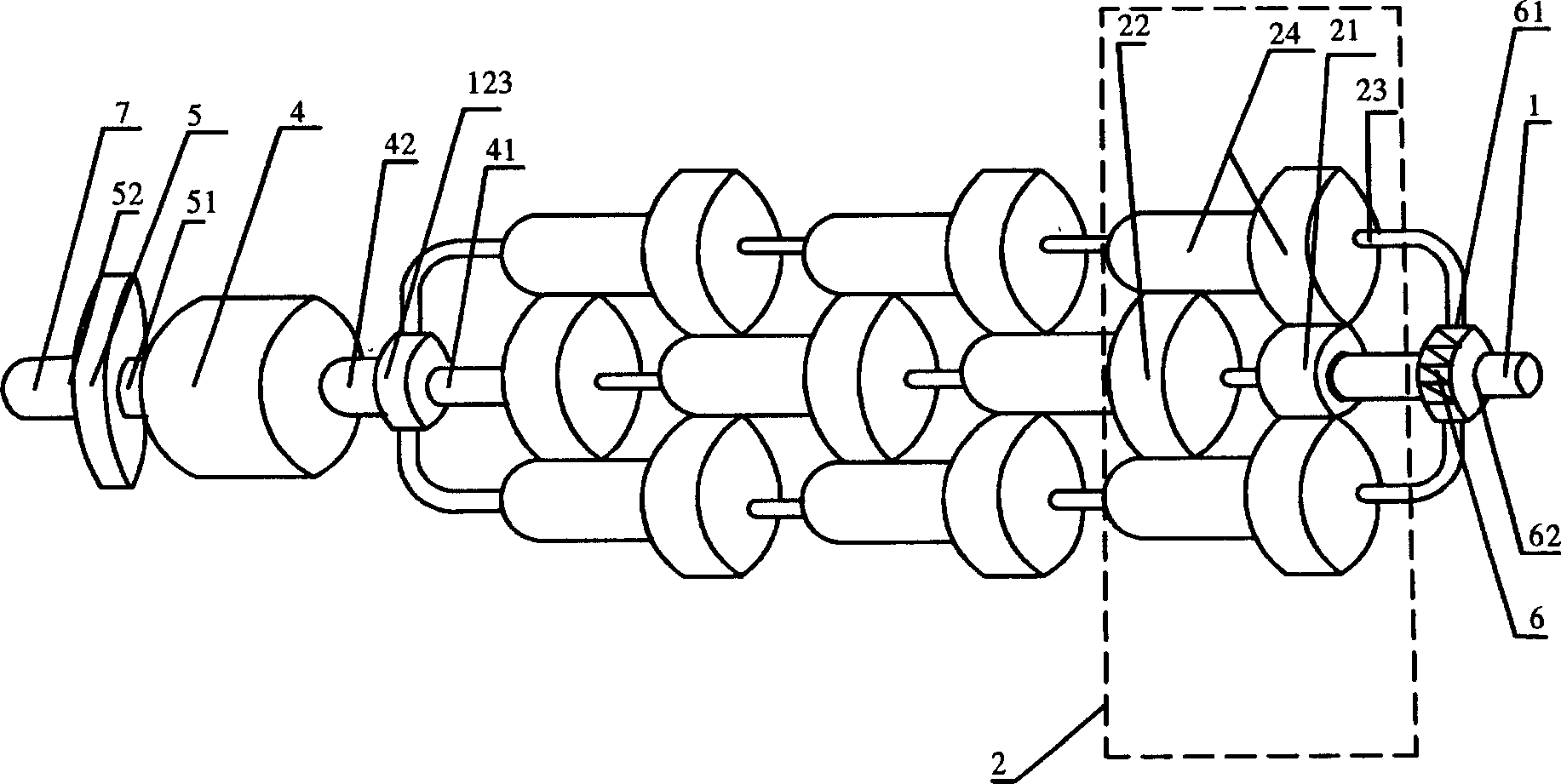

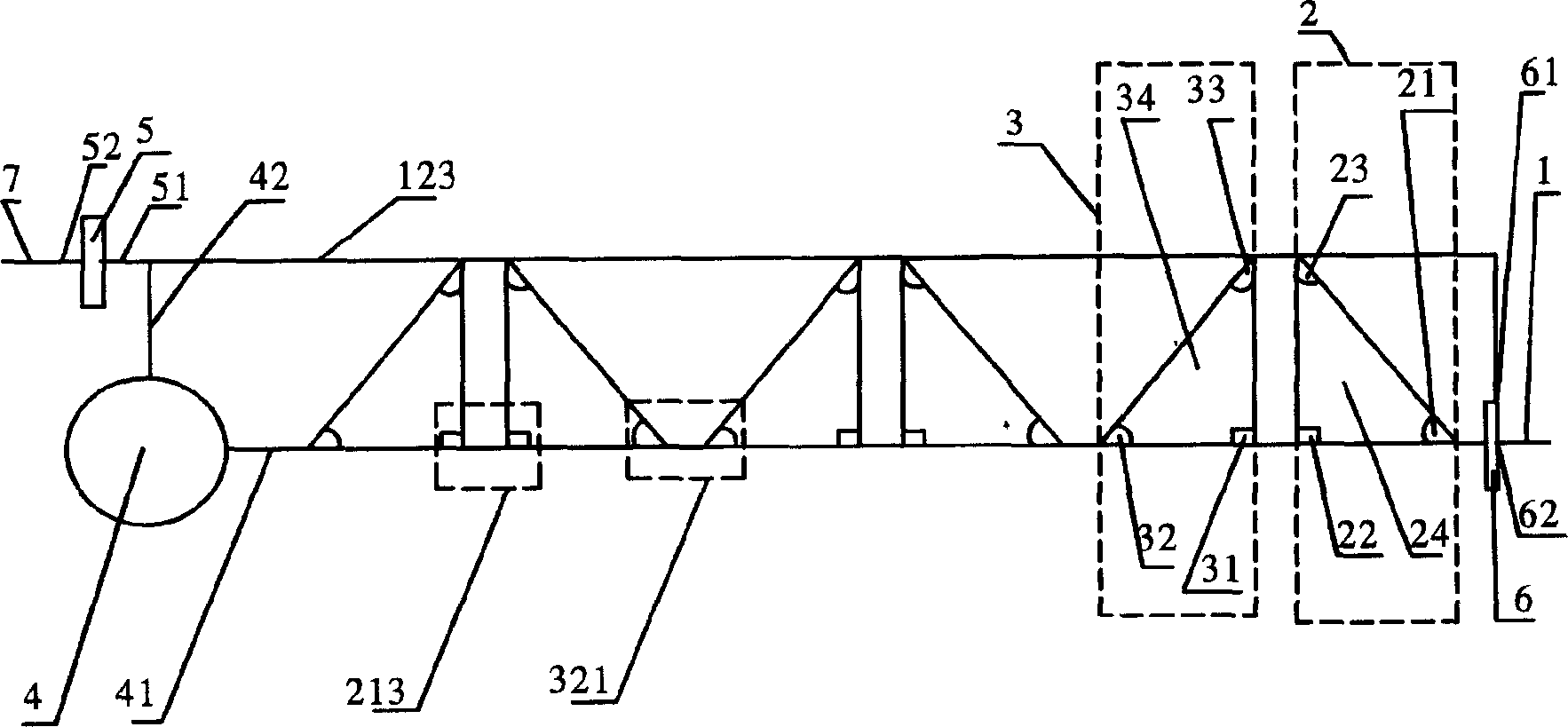

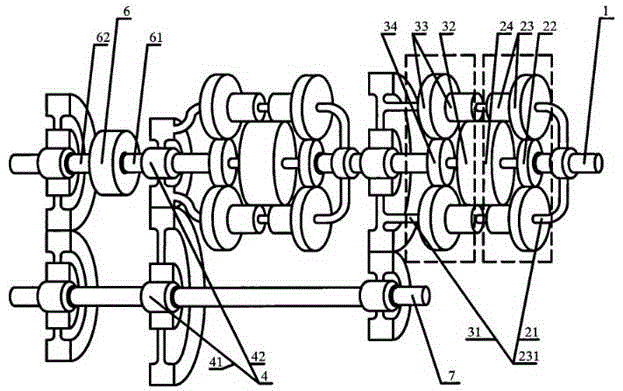

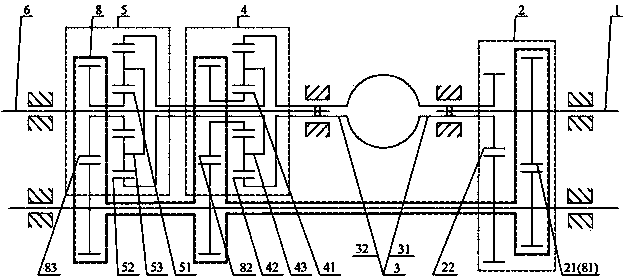

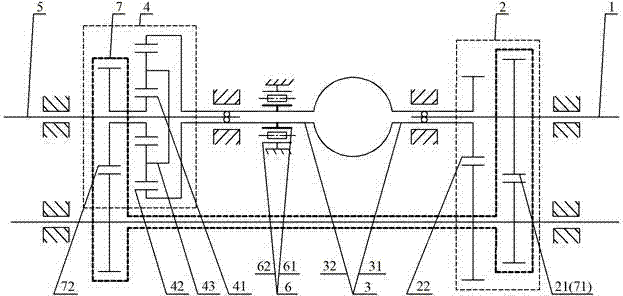

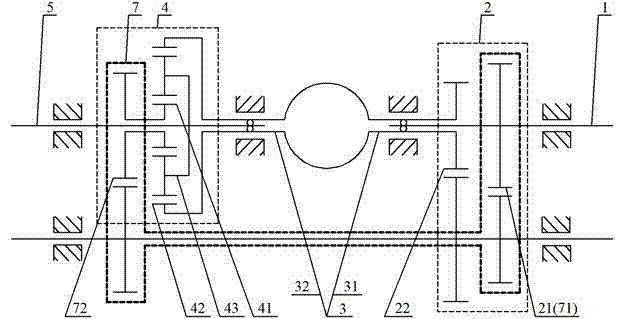

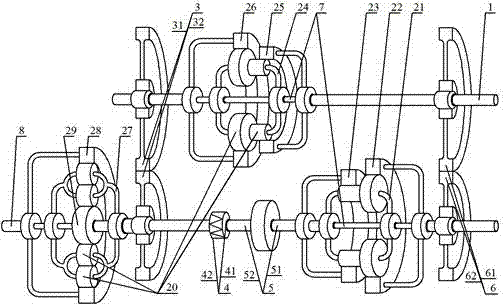

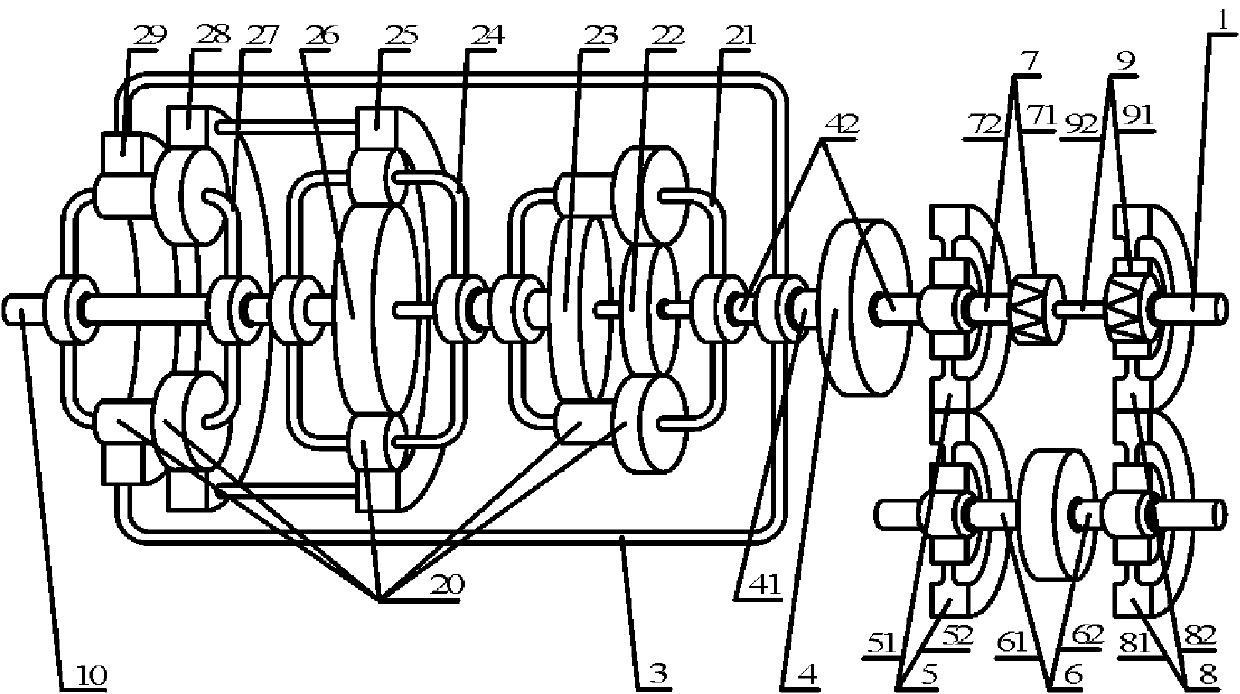

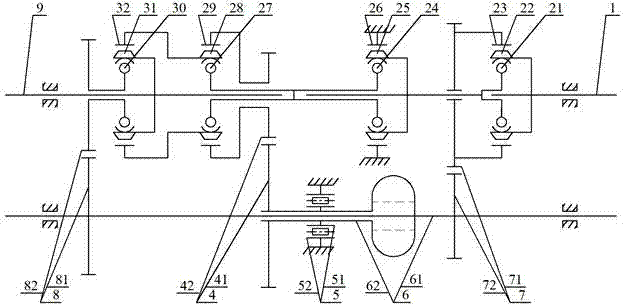

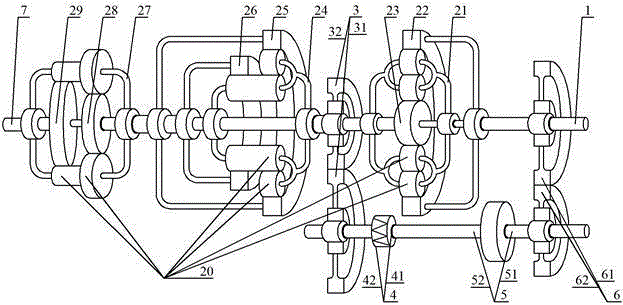

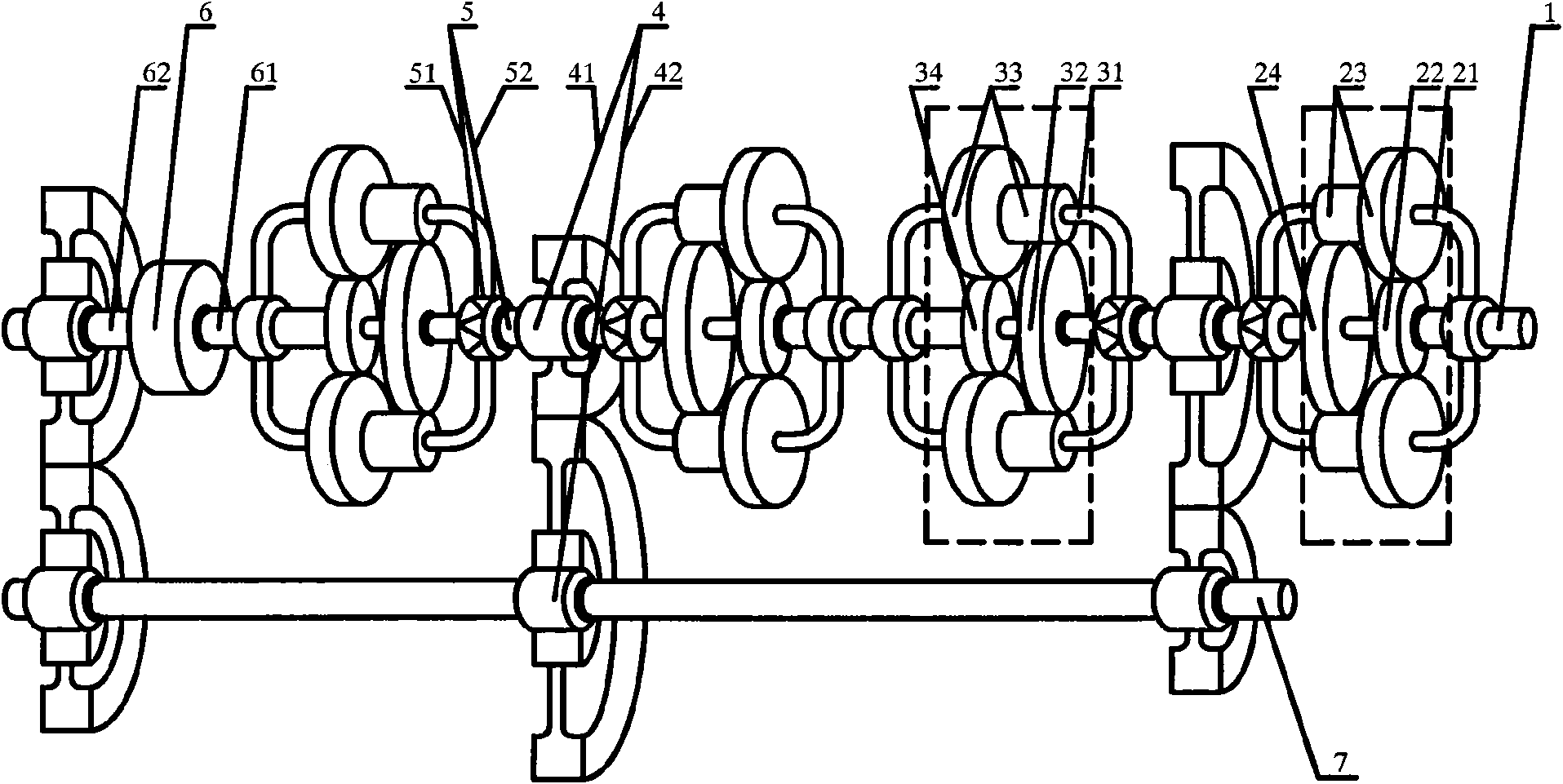

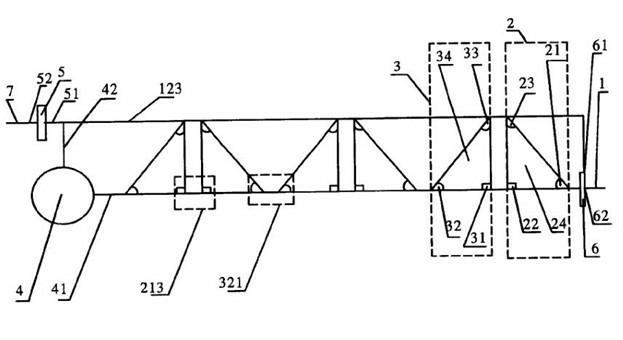

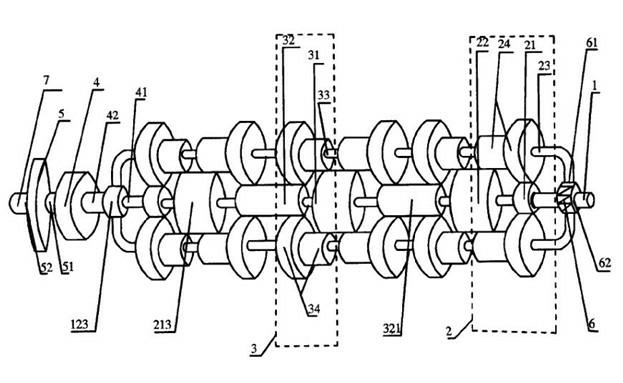

The invention provides a simultaneous multi-gear meshing transmission of a composite hydraulic torque converter. According to the technical scheme, the simultaneous multi-gear meshing transmission is mainly characterized in that an output end 62 is connected with an input end 41, all output ends 42 are connected with an output shaft 7, two torque increasing units 2 and two speed regulating units 3 are arranged between an input shaft 1 and the output shaft 7, a first input element 22 is connected with the input shaft, other input elements 22 are connected with previous connecting elements 34 respectively, the last connecting element 34 is connected with an input end 61, all connecting elements 24 are connected with next input elements 32 respectively, and a public output element 231 is directly connected with the input ends 41 matching with the torque increasing units 2 and the speed regulating units 3 respectively.

Owner:吴志强

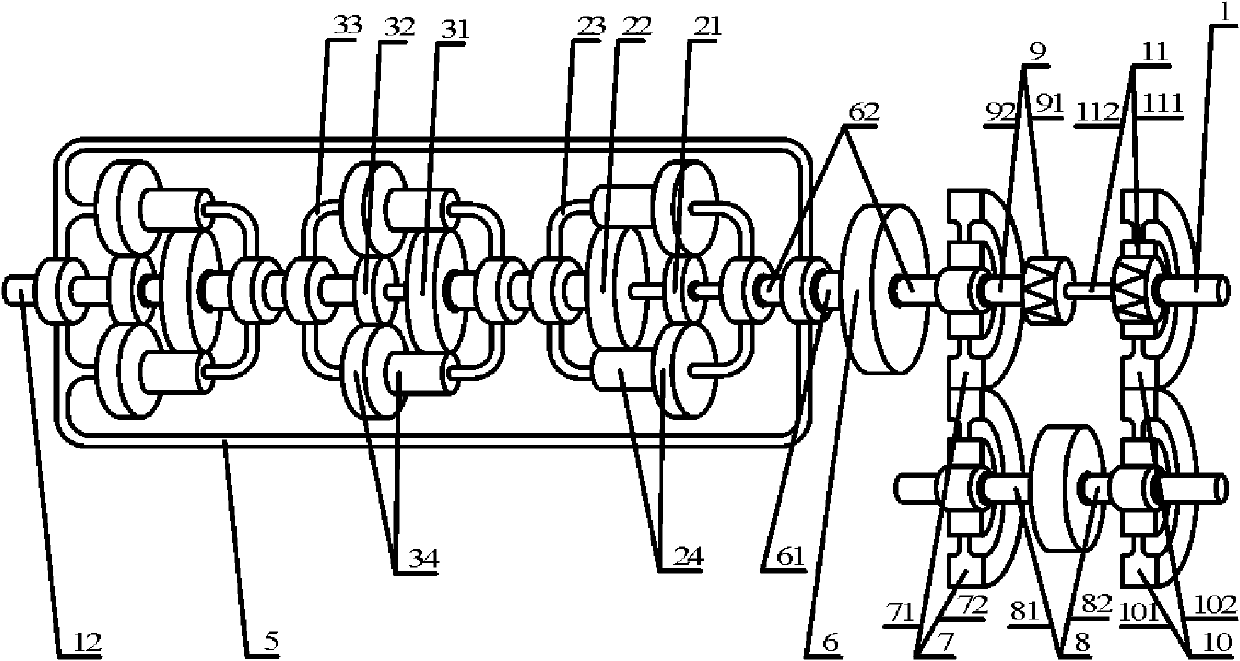

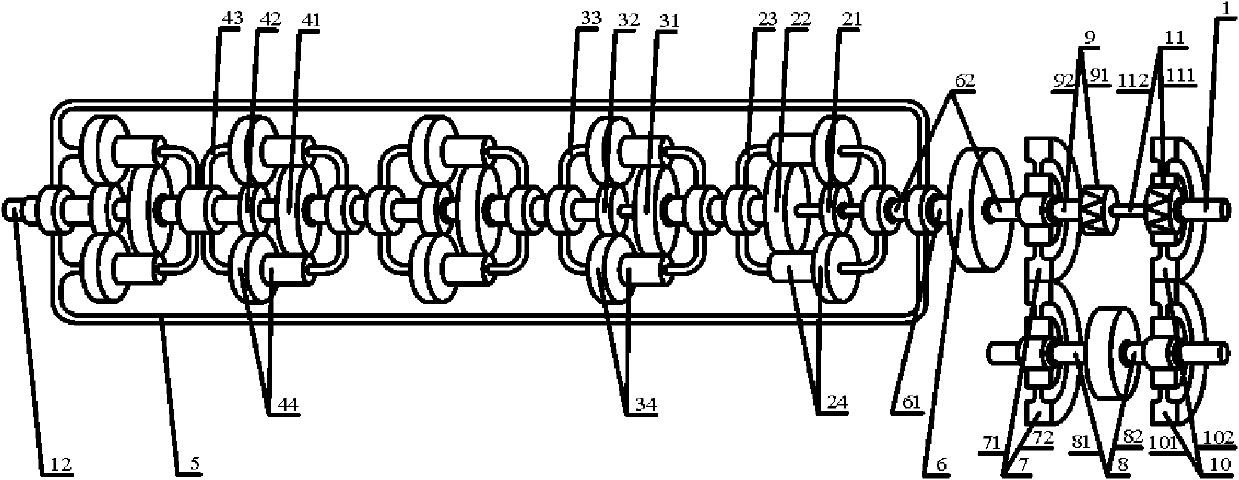

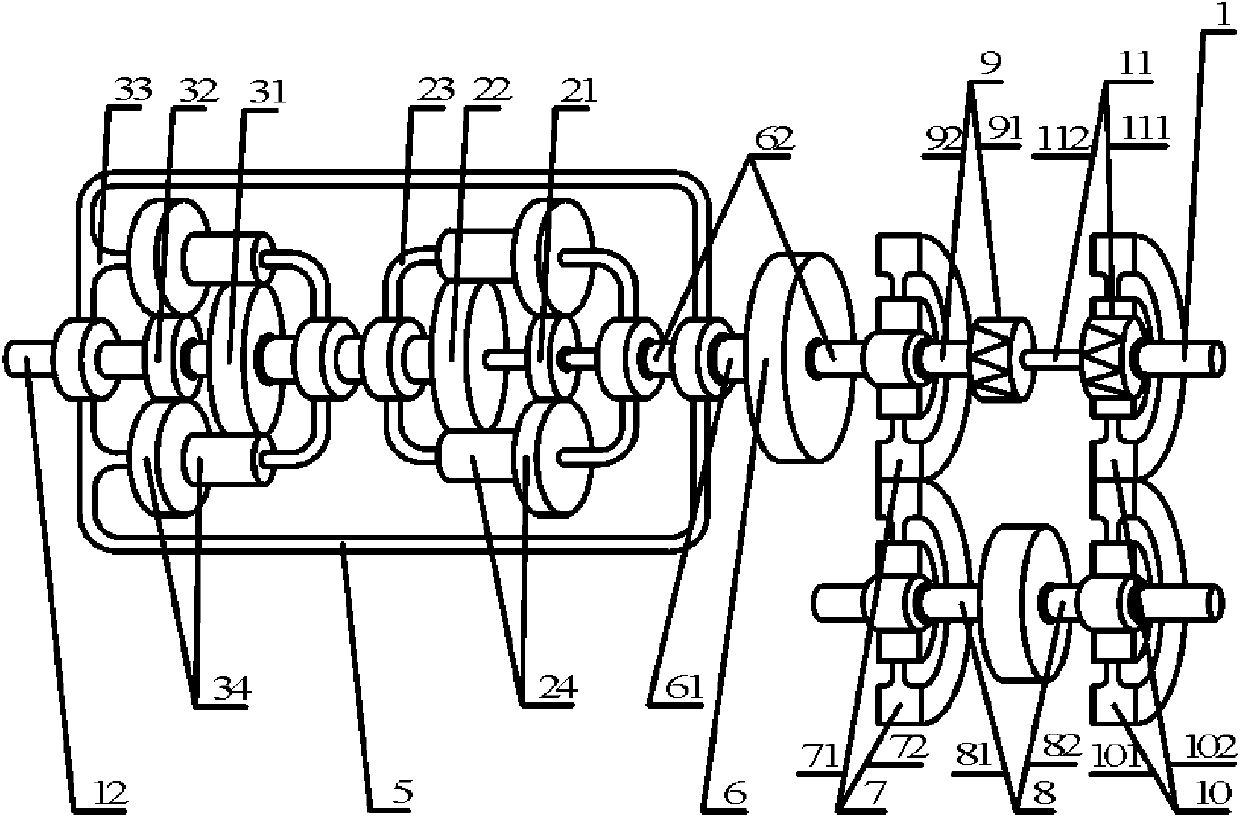

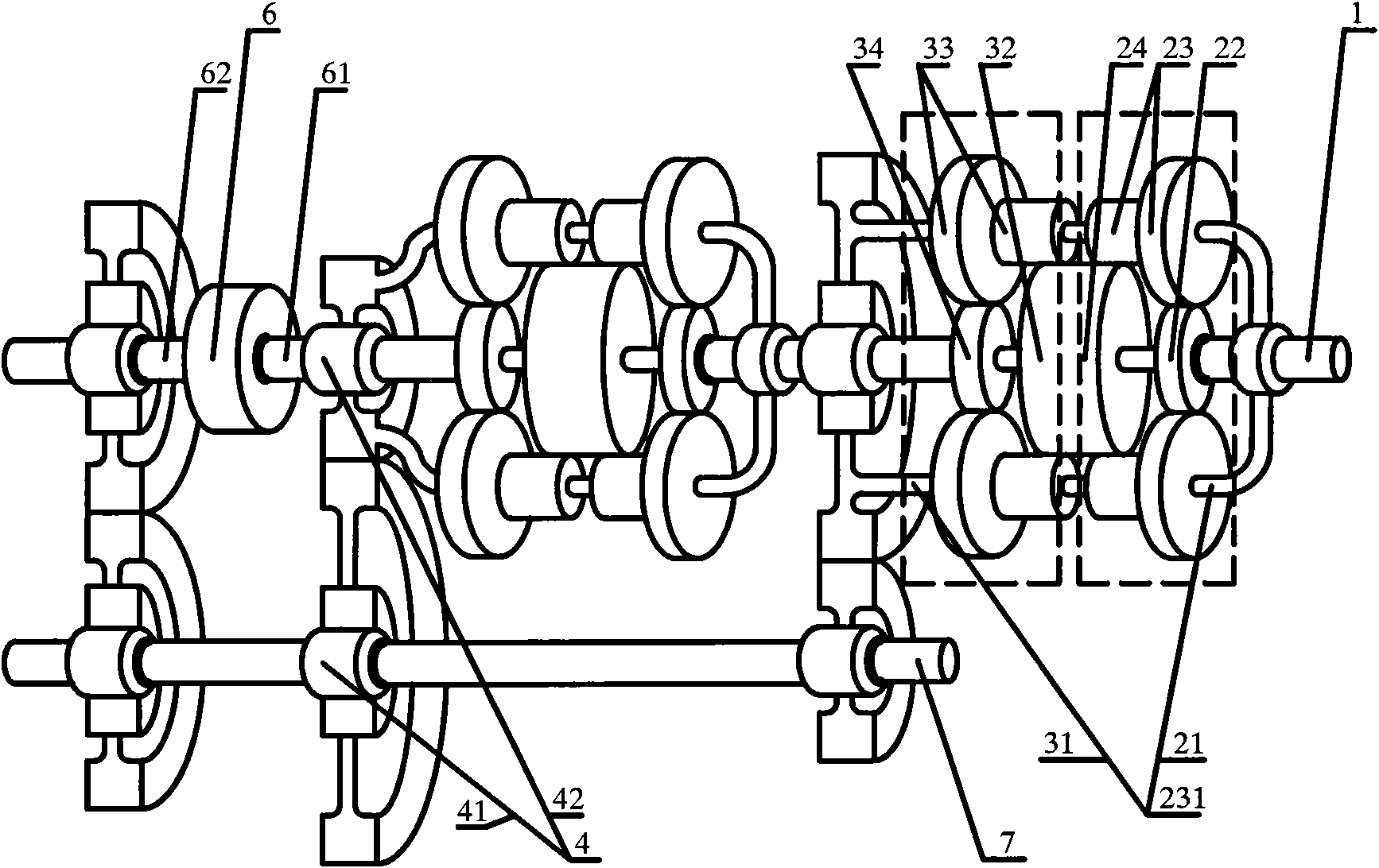

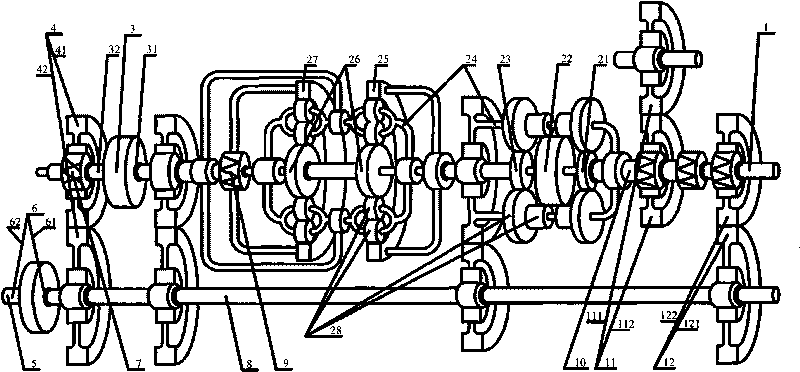

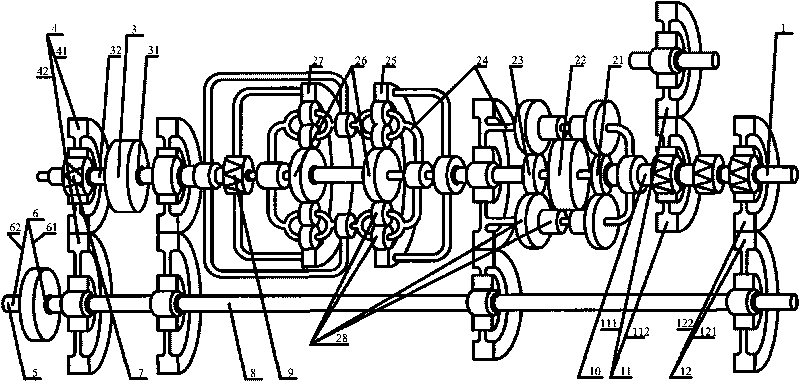

Stepless speed changer

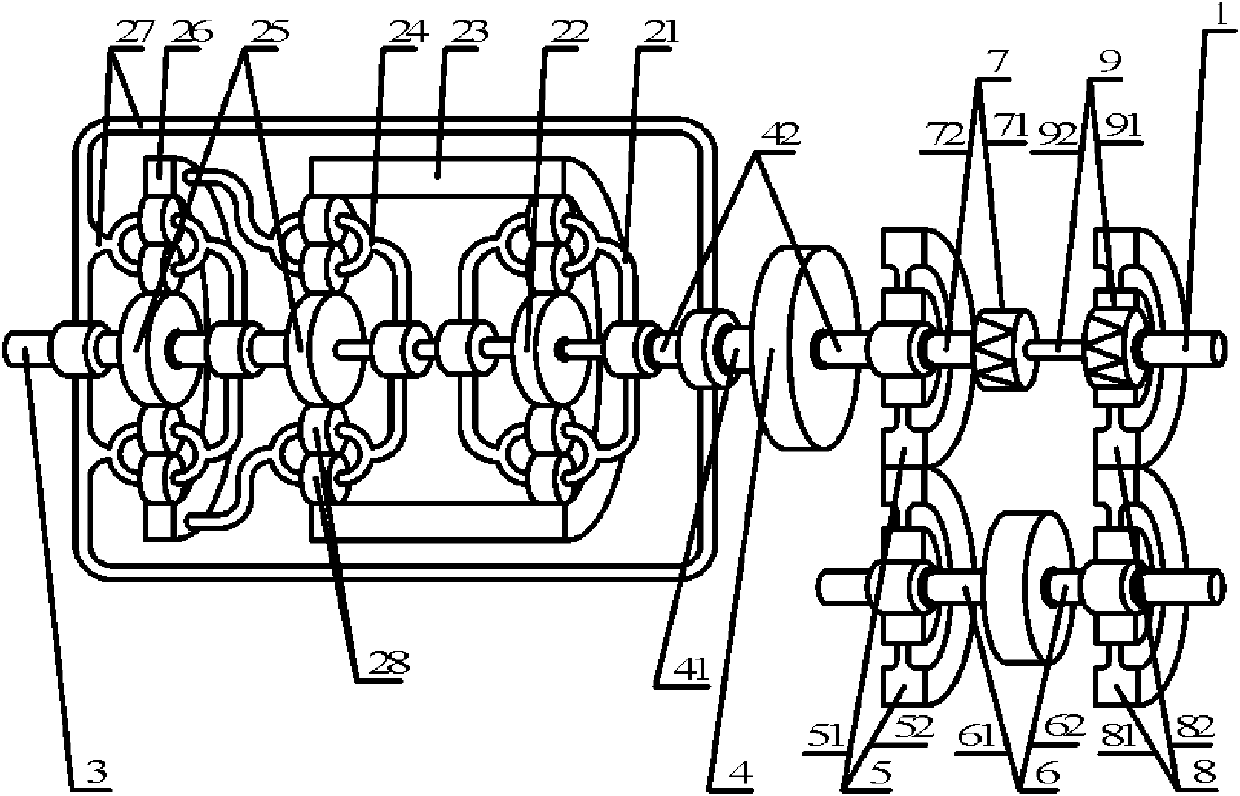

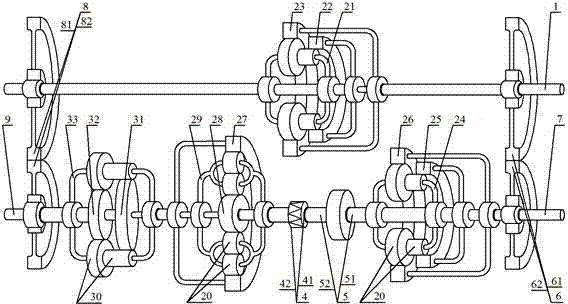

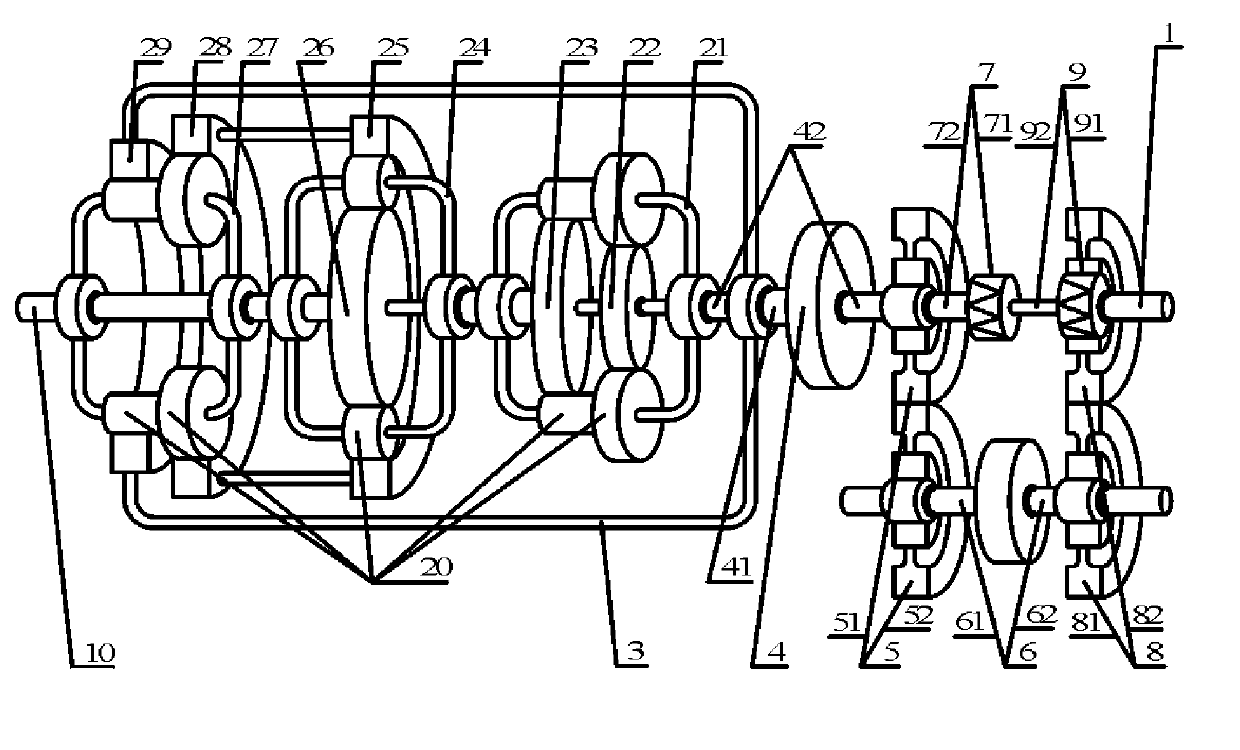

The invention provides a stepless speed changer which is technically characterized in that a confluence output component 22 is connected with a first shunt input component 31, and each shunt input component 31 of the rest is connected with a last second shunt output component 33 matched with the shunt input component 31; each first shunt output component 32 is connected with an output shaft 12, and a connecting frame 5 is connected with the final second shunt output component 33, a plurality of components outside the stepless speed changer and the input end 61 of a speed changing mechanism 6; the output end 62 of the speed changing mechanism 6 is connected with a second confluence input component 23, an input gear 71 of an input gear pair 7 and the output end 92 of a fixed one-way clutch 9, and an output gear 72 of the input gear pair 7 is connected with the input end 81 of a connector 8; and the output end 82 of the connector 8 is connected with an input gear 101 of an output gear pair 10, an output gear 102 of the output gear pair 10 is connected with the input end 111 of a one-way clutch 11, and the output end 112 of the one-way clutch 11 is connected with a first confluence input component 21 and an input shaft 1.

Owner:吴志强

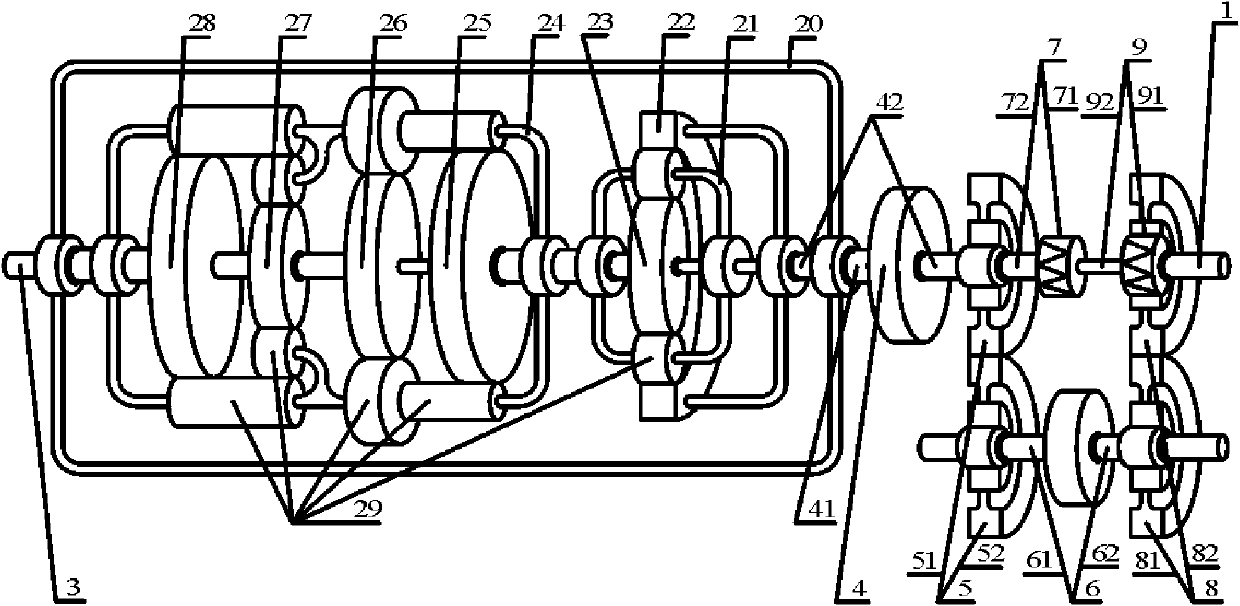

Compound closed planetary cone-shaped stepless speed change concurrent starter

InactiveCN101761630AIncreased transmission power and transmission efficiencySimple structureToothed gearingsClutchVariator

The invention provides a compound closed planetary cone-shaped stepless speed change concurrent starter. The key points of the technical scheme are that a share output planet carrier 25 is connected with an input gear ring 21, a large connecting gear ring 23 and an output gear ring 24; an input planet carrier 26 and an output planet carrier 28 are connected with a connecting gear 27 and an output gear 29; the output gear ring 24 is connected with the input planet carrier 26; the output planet carrier 28 is connected with an input end 91 of a one-way clutch 9, a plurality of elements except for the compound closed planetary cone-shaped stepless speed change concurrent starter and an input end 31 of a closed planetary cone-shaped stepless transmission 3; the one-way clutch 9 is connected with the input gear ring 21; the closed planetary cone-shaped stepless transmission 3 is connected with a clutch 7; an output end 72 of the clutch 7, the share output planet carrier 25 and the output gear 29 are connected with transmission gear pairs 4; and various transmission gear pairs 4, a neutral and reverse gear mechanisms 6 and input gears 121 of starting gear pairs 12 are connected with a gear pair connecting shaft 8.

Owner:吴志强

Continuously variable transmission

The invention provides a continuously variable transmission. According to the key point of the technical scheme, a speed accelerating unit 2, a speed changing unit 4 and a speed transferring unit 5 are linked with an input shaft 1; the speed accelerating unit 2 is linked with a hydrodynamic driving device 3; the hydrodynamic driving device 3 and a controller 7 are linked with the speed changing unit 4; the speed changing unit 4 is linked with the speed transferring unit 3 and the speed transferring unit 5 is linked with an output shaft 6.

Owner:吴志强

Compound type hydraulic drive device

InactiveCN103939559AMeet the needs of useChange gear ratioGearboxesFluid gearingsControl theoryMechanical engineering

Owner:吴志强

Composite type hydraulic torque converter with external overflow valve

InactiveCN102022509AImprove power efficiencyImprove transmission efficiencyFluid gearingsEngineeringPinion

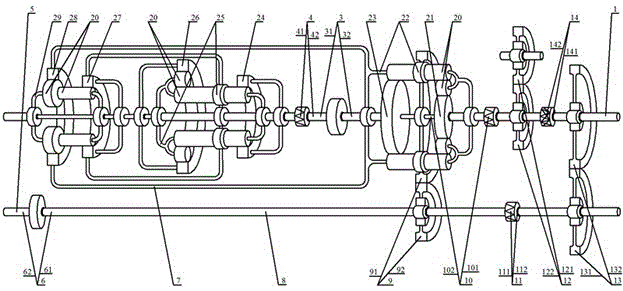

The invention provides a composite type hydraulic torque converter with an external overflow valve. The technical scheme comprises the following key points: a double-star planet carrier 21 is connected with a pinion 22 and a coupling gear ring 23; a coupling planet carrier 24 is connected with the coupling gear ring 23, an output pinion 25 and an input gear ring 26; the output pinion 25 is connected with an output shaft 3; an output planet carrier 27 is connected with the output pinion 25, the input gear ring 26, a plurality of components outside the composite type hydraulic torque converter and an input end 41 of a speed change mechanism 4; an output end 42 of the speed change mechanism 4 is connected with the double-star planet carrier 21, an input gear 51 of an input gear pair 5, and an output end 72 of a fixed one-way clutch 7 respectively; an output gear 52 of the input gear pair 5 is connected with an input end 61 of the hydraulic torque converter 6 with the external overflow valve; an output end 62 of the hydraulic torque converter 6 is connected with an input gear 81 of an output gear pair 8; an output gear 82 of the output gear pair 8 is connected with an input end 91 of a one-way clutch 9; and an output end 92 of the one-way clutch 9 is connected with the pinion 22 and an input shaft 1.

Owner:吴志强

Compound type hydraulic torque converter with overflow valve arranged externally and continuously variable transmission

ActiveCN103939565AImprove power efficiencyImprove transmission efficiencyFluid gearingsGearing detailsGear wheelEngineering

The invention provides a compound type hydraulic torque converter with an overflow valve arranged externally. According to the technical scheme, the compound type hydraulic torque converter with the overflow valve arranged externally is characterized in that a small input gear ring 25 and an input gear pair 6 are connected with an input shaft 1, a large output gear ring 26 is connected with an output gear pair 3, the output gear pair 3 is connected with a collector planet carrier 27, the input gear pair 6 is connected with a large input gear ring 22, a small output gear ring 23 is connected with a hydraulic torque converter body 5 with the overflow valve arranged externally, the hydraulic torque converter body 5 with the overflow valve arranged externally is connected with a one-way clutch 4 and a collector gear 29, a fixed planet carrier 21 and a fixed planet carrier 24 are connected with a fixed component through connecting shafts 7, and a large output gear ring 28 is connected with an output shaft 8.

Owner:济宁高新科达科技项目服务有限公司

Compound type torque limited type aqueous medium fluid coupling and starter

InactiveCN105090391AImprove power efficiencyImprove transmission efficiencyToothed gearingsFluid gearingsFluid couplingElectromagnetic clutch

The invention provides a compound type torque limited type aqueous medium fluid coupling and a starter. According to the technical scheme, an input shaft (1) is connected with a starter gear pair (13) and an overrun clutch (14), and the overrun clutch (14) is connected with a first one-way clutch (10) and a starter gear pair (12); the first one-way clutch (10) is connected with an input pinion (21), an output planet carrier (22) is connected with a connecting frame (7) and an output gear pair (9), and a connecting shaft (8) is connected with an idle gear engaging mechanism (6), the output gear pair (9) and an electromagnetic clutch (11); the electromagnetic clutch (11) is connected with the starter gear pair (13), the idle gear engaging mechanism (6) is connected with an output shaft (5), and the connecting frame (7) is connected with an input gear ring (28); an output gear ring (27) is connected with an input planet carrier (25), a small output gear ring (24) is connected with a second one-way clutch (4), and the second one-way clutch (4) and the first one-way clutch (10) are connected with the torque limited type aqueous medium fluid coupling (3); and the torque limited type aqueous medium fluid coupling (3) is connected with a large input gear (23).

Owner:吴志强

Composite gear chain type stepless variable speed unit

InactiveCN101598204AImprove power efficiencyImprove transmission efficiencyGearingGear wheelChain type

The invention provides a composite gear chain type stepless variable speed unit which has the technical scheme that a first input wave generator 21 is connected with an input shaft 1 and connected with a first output flexible gear 22 and a first connecting rigid gear 23; the first connecting rigid gear 23 is connected with the first output flexible gear 22 and a first output wave generator 24; the first output wave generator 24 is connected with a second input wave generator 21; the second input wave generator 21 is connected with a second output flexible gear 22 and a second connecting rigid gear 23; the second connecting rigid gear 23 is connected with the second output flexible gear 22 and a second output wave generator 24; the second output wave generator 24 is connected with the input end 31 of a gear chain type stepless variable speed unit 3; and the output end 32 of the gear chain type stepless variable speed unit 3, the first output flexible gear 22 and the second output flexible gear 22 are respectively connected with input gears 41 of matched gear pairs 4.

Owner:吴志强

Compound type double guide wheel hydraulic torque converter

InactiveCN102022505AImprove power efficiencyImprove transmission efficiencyFluid gearingsControl theoryTorque converter

The invention provides a compound type double guide wheel hydraulic torque converter. The technical scheme comprises the following key points that: a compound planet carrier 21 is connected with an input small gear 22 and an output gear 23; the output gear 23 is connected with an input planet carrier 24; the input planet carrier 24 is connected with an output gear ring 25 and an output big gear 26; the output gear ring 25 is connected with an input gear ring 28; an output planet carrier 27 is connected with the input gear ring 28 and an output small gear ring 29, and is also connected with the output big gear 26 and an output shaft 10; a connecting frame 3 is connected with the output small gear ring 29, other components and a variable speed gear 4; the variable speed gear 4 is respectively connected with the compound planet carrier 21, an input gear pair 5 and a fixed one-way clutch 7; the input gear pair 5 is connected with a double guide wheel hydraulic torque converter 6; the double guide wheel hydraulic torque converter 6 is connected with an output gear pair 8; the output gear pair 8 is connected with a one-way clutch 9; and the one-way clutch 9 is respectively connected with the input small gear 22 and an input shaft 1.

Owner:吴志强

Composite centripetal turbine type hydraulic torque converter

InactiveCN102022506AImprove power efficiencyImprove transmission efficiencyFluid gearingsEngineeringTurbine

The invention provides a composite centripetal turbine type hydraulic torque converter. The key point of the technical scheme is that: a connection planet carrier 23 is connected with an input gear 21, an input gear ring 22, an output big gear ring 24 and an output gear 25; the output gear 25 is connected with an output shaft 3; an input planet carrier 27 is connected with the output big gear ring 24, the output gear and an output gear ring 26; a connection carrier 29 is connected with the output gear ring 26, a plurality of components except for the composite centripetal turbine type hydraulic torque converter and the input end 41 of a speed change mechanism 4; the output end 42 of the speed change mechanism 4 is connected with the input gear 22, an input gear 51 of an input gear pair 5 and the output end 72 of a fixed one-way clutch 7 respectively; an output gear 52 of the input gear pair 5 is connected with the input end 61 of the centripetal turbine type hydraulic torque converter 6; the output end 62 of the centripetal turbine type hydraulic torque converter 6 is connected with an input gear 81 of an output gear pair 8; an output gear 82 of the output gear pair 8 is connected with the input end 91 of a one-way clutch 9; and the output end 92 of the one-way clutch 9 is connected with the input gear 21 and an input shaft 1 respectively.

Owner:吴志强

Composite impeller type hydraulic torque converter

InactiveCN102022513AImprove power efficiencyImprove transmission efficiencyFluid gearingsImpellerGear wheel

The invention provides a composite impeller type hydraulic torque converter. The key point of the technical scheme is that: a connecting planet carrier 23 is connected with a bull gear 21, an input pinion gear 22, a connecting pinion gear 24 and an output gear 27; the output gear 27 is connected with an output shaft 3; the connecting pinion gear 24 is connected with an input planet carrier 25; the input planet carrier 25 is connected with the output gear 27 and an output pinion gear 26; a connecting rack 29 is connected with the output pinion gear 26, a plurality of elements apart from those of the invention are connected with the input end 41 of a speed change mechanism 4; the output end 42 of the speed change mechanism 4 is connected with the bull gear 21, an input gear 51 of an input gear pair 5 and the output end 72 of a fixed one-way clutch 7; an output gear 52 of the input gear pair 5 is connected with the input end 61 of an impeller type hydraulic torque converter 6; the output end 62 of the impeller type hydraulic torque converter 6 is connected with an input gear 81 of an output gear pair 8; an output gear 82 of the output gear pair 8 is connected with the input end 91 of a one-way clutch 9; and the output end 92 of the one-way clutch 9 is connected with the input pinion gear 22 and an input shaft 1.

Owner:吴志强

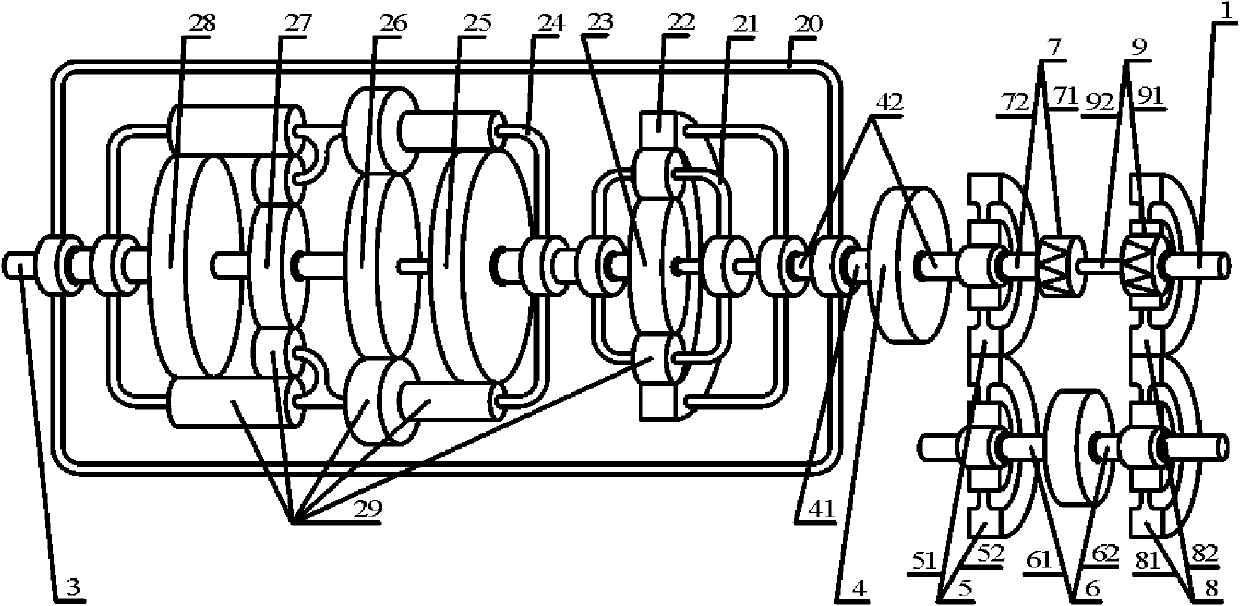

Compound axial-flow type hydraulic torque converter and continuously variable transmission

ActiveCN103939569AImprove power efficiencyImprove transmission efficiencyGearboxesFluid gearingsWave formControl theory

The invention provides a compound axial-flow type hydraulic torque converter. According to the technical scheme, the compound axial-flow type hydraulic torque converter is characterized in that a collector wave form generator 28 and an input gear pair 6 are connected with an input shaft 1, the input gear pair 6 is connected with an axial-flow type hydraulic torque converter body 5, the axial-flow type hydraulic torque converter body 5 is connected with an output gear pair 4, the output gear pair 4 is connected with an input flexible gear 22 and a one-way clutch 3, the one-way clutch 3 is connected with a fixed component, an output wave form generator 21 is connected with a connection flexible gear 24, a connection wave form generator 29 is connected with a collector rigid gear 27, and an output flexible gear 26 is connected with an output shaft 7.

Owner:济宁高新科达科技项目服务有限公司

Compound type centripetal turbine hydraulic torque converter

InactiveCN105333089AImprove power efficiencyImprove transmission efficiencyFluid gearingsGearing detailsTurbineControl theory

The invention provides a compound type centripetal turbine hydraulic torque converter. According to the technical scheme, the key point is that an input large gear ring (22) is connected with an input gear pair (6) and an input shaft (1); an output gear (23) is connected with a junction gear (28); an input gear pair (6) is connected with a centripetal turbine hydraulic torque converter (5); the centripetal turbine hydraulic torque converter (5) is connected with a one-way clutch (4) and an output gear pair (3); the output gear pair (3) is connected with a connection planetary carrier (24); an output small gear ring (26) is connected with a junction planetary carrier (27); and an output gear (29) is connected with an output shaft (7).

Owner:吴志强

Multi-gear simultaneous meshing variable speed unit

InactiveCN101598197AAvoid physical laborSimple structureToothed gearingsFluid gearingsControl theoryClutch

Owner:吴志强

Composite axial-flow hydrotransmitter

InactiveCN102022514AImprove power efficiencyImprove transmission efficiencyFluid gearingsGear wheelEngineering

The invention provides a composite axial-flow hydrotransmitter. The invention adopts the technical scheme that an output planet carrier (21) is connected with an input gearwheel (25), an input great gear rim (22) and an input pinion (23), a connection planet carrier (24) is connected with the input gearwheel (25), an output gear (26), an output pinion (27) and an output gearwheel (28), the output gear (26) is connected with the output pinion (27) and an output shaft (3), a connection carrier (20) is connected with the output gearwheel (28), a plurality of other elements and the input end (41) of a gear shifting mechanism (4), the output end (42) of the gear shifting mechanism (4) is respectively connected with the input great gear rim (22), an input gear (51) of an input gear pair (5) and the output end (72) of a fixed one-way clutch (7), an output gear (52) of the input gear pair (5) is connected with the input end (61) of the axial-flow hydrotransmitter (6), the output end (62) of the axial-flow hydrotransmitter (6) is connected with an input gear (81) of an output gear pair (8), an output gear (82) of the output gear pair (8) is connected with the input end (91) of the one-way clutch (9), and the output end (92) of the one-way clutch (9) is respectively connected with the input pinion (23) and an input shaft (1).

Owner:吴志强

Compound hydraulic special-shaped coupler and starter

InactiveCN104482161AImprove power efficiencyImprove transmission efficiencyTransmission elementsFluid gearingsEngineeringClutch

The invention provides a compound hydraulic special-shaped coupler and a starter. The technical proposal key points are as follows: an input gear ring (22) is connected with a starting gear pair (11) and an overturning coupler (12); an input gear (4) is connected with an output planet carrier (21) and an internal and external engaged gear ring (24); an output gear ring (25) is connected with an input planet carrier (27); an output duplex planet carrier (26), an output small gear ring (29) and a starting input gear pair (13) are connected with an empty shift mechanism (8); an output large gear ring (28) is connected with a speed change mechanism (10); the speed change mechanism (10) is connected with an output gear pair (7) and an input gear pair (9); the output gear pair (7) is connected with the hydraulic special-shaped coupler (6); the hydraulic special-shaped coupler (6) is connected with the input gear ring (22).

Owner:吴志强

Compound toothed chain stepless speed change concurrent starter

InactiveCN101761624AIncreased transmission power and transmission efficiencySimple structureToothed gearingsClutchVariator

The invention provides a compound toothed chain stepless speed change concurrent starter. The key points of the technical scheme are that a first output planet carrier (24) is connected with an input gear (21), a connecting gear (22) and an output gear (23); a second output planet carrier (24) is connected with an input gear ring (25), a connecting pinion (26) and an output gear ring (27); the output gear ring (23) is connected with the input gear ring (25); the output gear ring (27) is connected with a one-way clutch (9) and a toothed chain stepless transmission (3); the one-way clutch (9) is connected with the input gear (21) and a plurality of elements except for the compound toothed chain stepless speed change concurrent starter; an output end (32) of the toothed chain stepless transmission (3) is connected with a clutch (7); an output end (72) of the clutch (7) and various output planet carriers (24) are connected with input gears (41) of transmission gear pairs (4) which are respectively matched; and output gears (42) of various transmission gear pairs (4), input ends (61) of neutral and reverse gear mechanisms (6) and input gears (121) of starting gear pairs (12) are connected with a gear pair connecting shaft (8).

Owner:吴志强

Composite overflow valve external type hydraulic torque converter and continuously variable transmission

ActiveCN104653744AImprove power efficiencyImprove transmission efficiencyTransmission elementsFluid gearingsPinionControl theory

The invention provides a composite overflow valve external type hydraulic torque converter. The composite overflow valve external type hydraulic torque converter is characterized in that an input pinion (22) and an output gear pair (7) are connected with an input shaft (1); an output large gear ring (23) is connected with an input gear ring (25); an output planet carrier (24) is connected with an input small gear ring (28); the input planet carrier (27) is connected with an input gear (26) and an input gear pair (6); the input gear pair (6) and an overrunning clutch (5) are connected with an overflow valve external type hydraulic torque converter (4); the overflow valve external type hydraulic torque converter (4) is connected with the output gear pair (7); an output gear ring (29) is connected with an output shaft (3).

Owner:山东百沃生物科技有限公司

Composite hydraulic torque converter with adjustable guide blade and stepless transmission

ActiveCN104712726AImprove power efficiencyImprove transmission efficiencyFluid gearingsControl theoryTorque converter

The invention provides a composite hydraulic torque converter with an adjustable guide blade. According to the technical scheme, the composite hydraulic torque converter is characterized in that a small input gear (22) and an output gear pair (7) are connected with an input shaft (1), a large output gear (23) is connected with the hydraulic torque converter (6) with the adjustable guide blade, the hydraulic torque converter (6) with the adjustable guide blade is connected with an overrunning clutch (5) and an input gear (4), the input gear (4) is connected with a large input gear ring (29), an output planetary frame (27) is connected with an output shaft (3), the output gear pair (7) is connected with an input gear (26), an input gear ring (25) is connected with the large input gear ring (29), and a connection planetary frame (24) is connected with a small input gear ring (28).

Owner:江苏九州传动科技有限公司

Composite pyramid type stepless variable speed unit

InactiveCN101598205AImprove power efficiencyImprove transmission efficiencyToothed gearingsEngineeringElectrical and Electronics engineering

The invention provides a composite pyramid type stepless variable speed unit which has the technical scheme that an input planetary carrier 21 is connected with an input shaft 1 and connected with a first output gear 23 and a first output small gear 27 by a group of planetary gears 22 on the input planetary carrier 21; the first output gear 23 is connected with a first input gear 24; a connecting planetary carrier 25 is connected with the first input gear 24, the first output small gear 27, a second output small gear 27 and a second output gear 23 by two groups of planetary gears on the connecting planetary carrier 25; the second output gear 23 is connected with a second input gear 24; an output planetary carrier 26 is connected with the second input gear 24 and the second output small gear 27 by a group of planetary gears 23 on the output planetary carrier 26 and connected with the input end 31 of a pyramid type stepless variable speed unit 3; and the output end 32 of the pyramid type stepless variable speed unit 3 and all output small gears 27 are respectively connected with input gears 41 of matched gear pairs 4.

Owner:吴志强

Compound valve control and refill type fluid coupling

InactiveCN102312981AImprove power efficiencyImprove transmission efficiencyFluid gearingsFluid couplingGear wheel

The invention provides a compound valve control and refill type fluid coupling. The key technical schemes are that: an input gear (22) is connected with an input shaft (1); a syntropy inner-outer meshed input planet carrier (21) is connected with a connection gear (22) and a connection gear ring (23); the gear ring (23) is connected with an output gear (24) and a syntropy inner-outer meshed connection planet carrier (25); the syntropy inner-outer meshed connection planet carrier (25) is connected with an input gear ring (27); the input gear ring (27) is connected with a syntropy inner-outer meshed output planet carrier (26) and an output connection gear (28); the output connection gear (28) is connected with the output gear (24) and an output shaft (3); the syntropy inner-outer meshed output planet carrier (26) is connected with elements except the compound valve control and refill type fluid coupling and an output gear pair (4); the output gear pair (4) is connected with a gear shifting mechanism (5); the gear shifting mechanism (5) is connected with a valve control and refill type fluid coupling (6); the valve control and refill fluid coupling (6) and the input gear pair (8) are connected with a one-way clutch (7); and the input gear pair (8) is connected with the syntropy inner-outer meshed input planet carrier (21).

Owner:吴志强

Composite type stepless transmission

InactiveCN102661371ASimple structureLow costToothed gearingsFluid gearingsControl theoryTransmission system

The invention aims to provide a composite type stepless transmission, which prolongs the service life of an engine and a transmission system, improves the travelling performance of a vehicle and ensures efficient work of the engine. The technical scheme is characterized in that a first acceleration unit (3) is connected with an input shaft (1); one end of a sharing output element (33) is connected with a one-way clutch (6), and the other end of the sharing output element (33) is sequentially connected with the other sharing output elements (33) and each sharing output element (23) and a controllable torque (4); other input elements (31) are connected with a respective previous output element (22); any output element (32) is connected with a respective next input element (21); and the last output element (22) is connected with the controllable torque (4).

Owner:吴志强

Compound axial-flow type torque converter

InactiveCN105333095AImprove power efficiencyImprove transmission efficiencyFluid gearingsPinionControl theory

The invention provides a compound axial-flow type torque converter. The technical solution of the compound axial-flow type torque converter has the following key points: an output planet carrier (23) is coupled with an input gear pair (4) that is coupled with an input planet carrier (25); an output gear (26) is coupled with an input planet carrier (27); an output gear ring (29) is coupled with an output shaft (3); an input gear (24), an input pinion (28) and an overrunning clutch (5) are coupled with an axial-flow type torque converter (6); the axial-flow type torque converter (6) is coupled with an output gear pair (7) that is coupled with an input gear ring (21) and an input shaft (1).

Owner:吴志强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com