System for treating solid discharge filth

A technology for treating system and dirt, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high use cost, lack of clean air, large investment cost, etc. The effect of low cost, simple structure and reduced investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

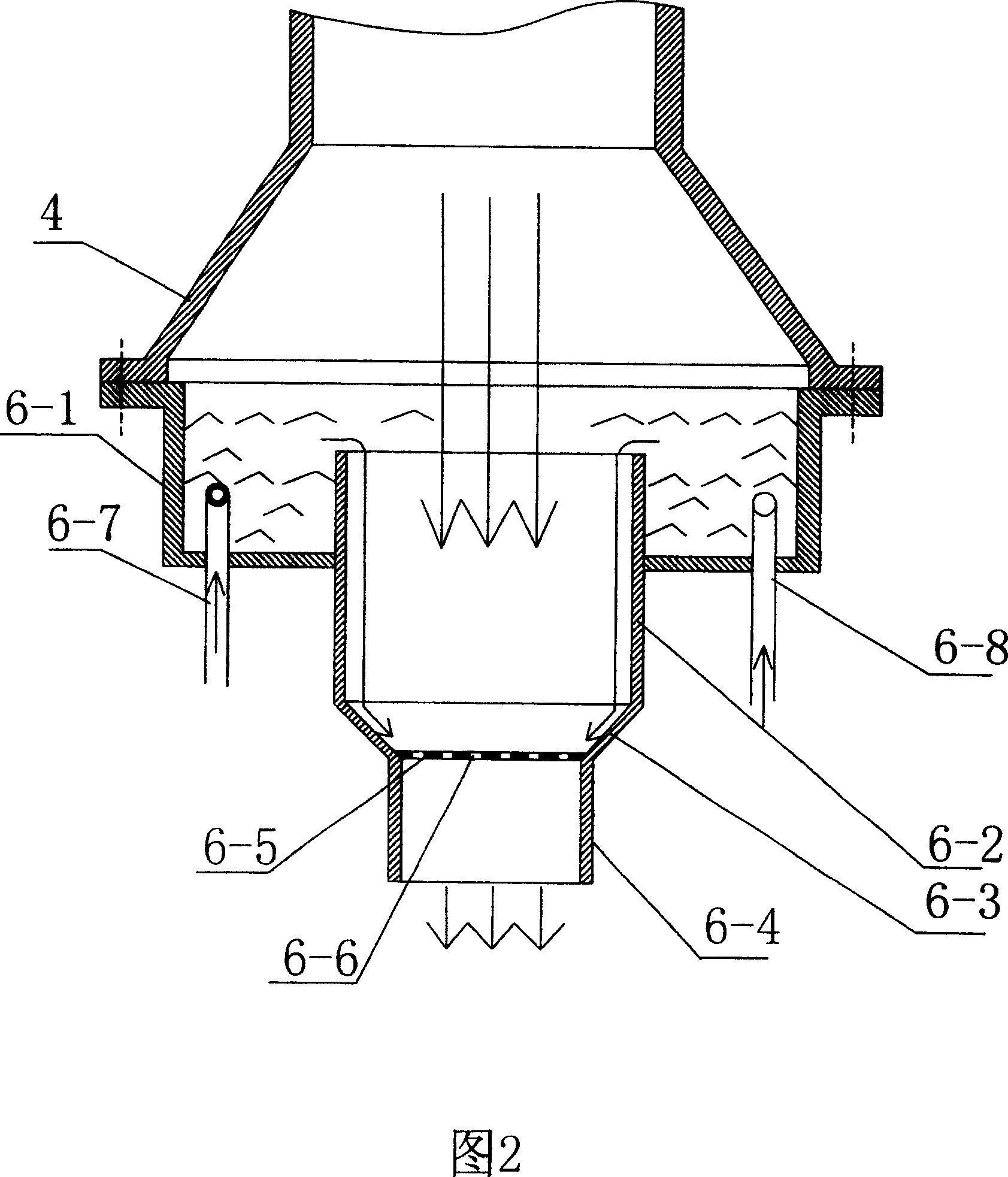

[0015] The atomization device 6 includes a water collecting pan 6-1 arranged between the delivery pipeline 3 and the sewage tank 8, two water inlet pipes 6-7 and 6-8 are arranged in the water collecting tray 6-1, and two water inlet pipes The ends of 6-7 and 6-8 are arranged in the tangential direction of the water collecting tray 6-1, and the water outlet direction is arranged forward. A through mixing cylinder is arranged in the water collection tray 6-1. The mixing cylinder is composed of two large and small cylinders 6-2 and 6-4. The two cylinders are transitionally connected by a conical cylinder 6-3. , Weld the horizontal dividing plate 6-5 that all opens circular through hole 6-6 on the connecting surface of conical cylinder 6-3 and lower cylinder 6-4.

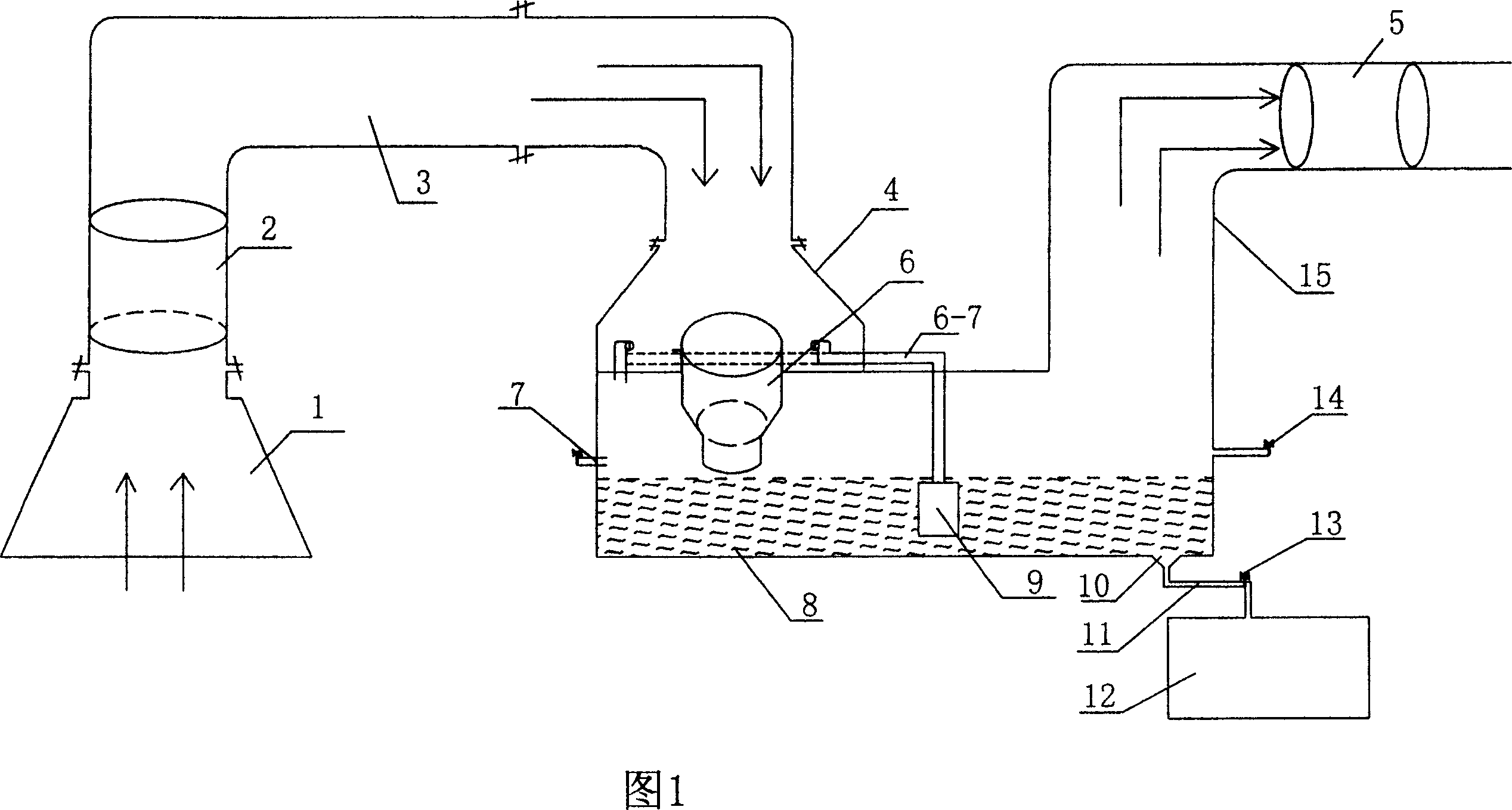

[0016] The conveying pipeline 3 is connected between the dirt collecting chamber 1 and the atomizing device 6, the exhaust fan 2 is arranged in the conveying pipeline 3, the atomizing device 6 is connected to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com