Polyamide resin film roll, and production method therefor

A polyamide and resin film technology, which is used in thin material processing, winding strips, flat products, etc., to achieve the effects of excellent pinhole resistance, low crystallization degree and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

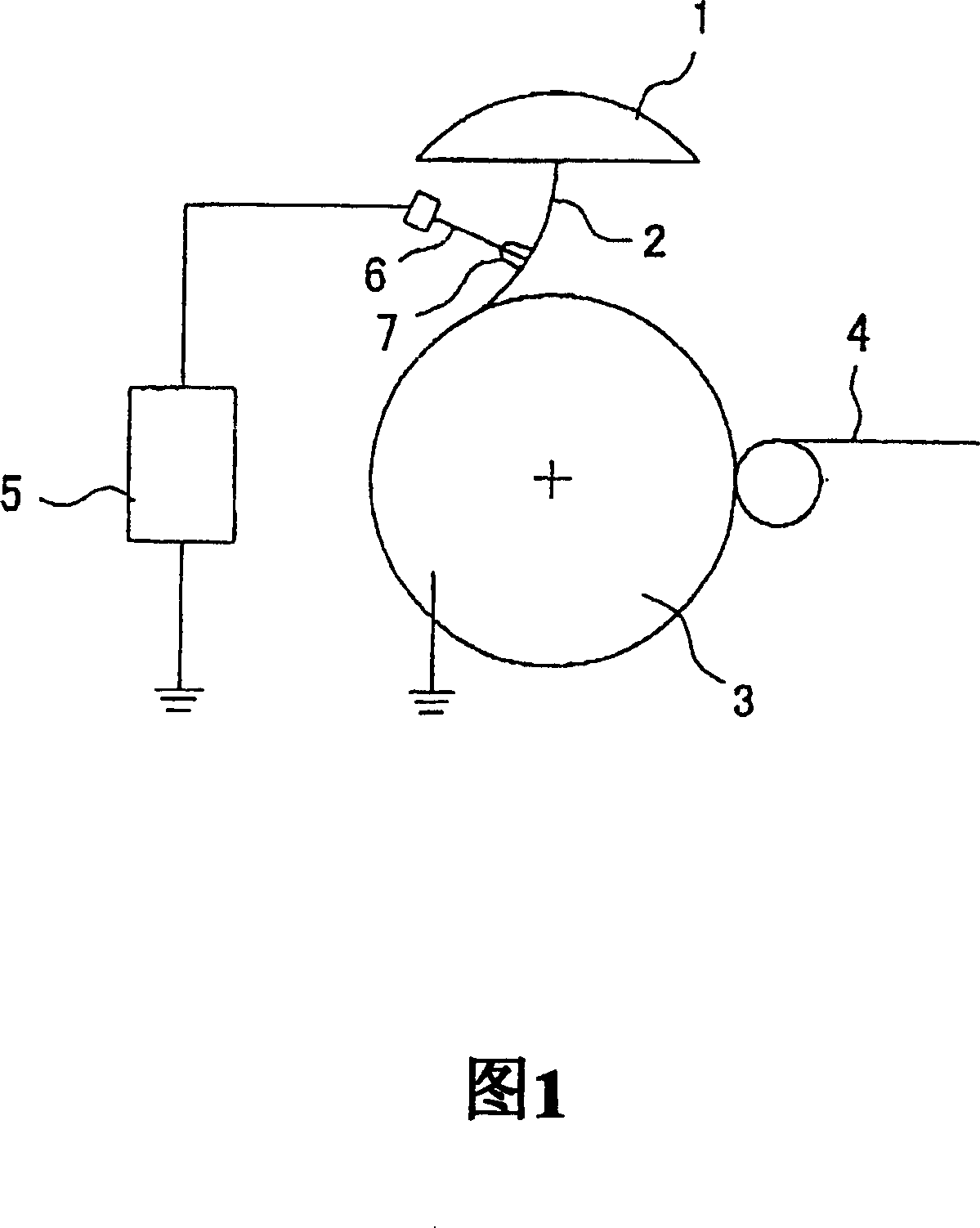

Method used

Image

Examples

Embodiment 1

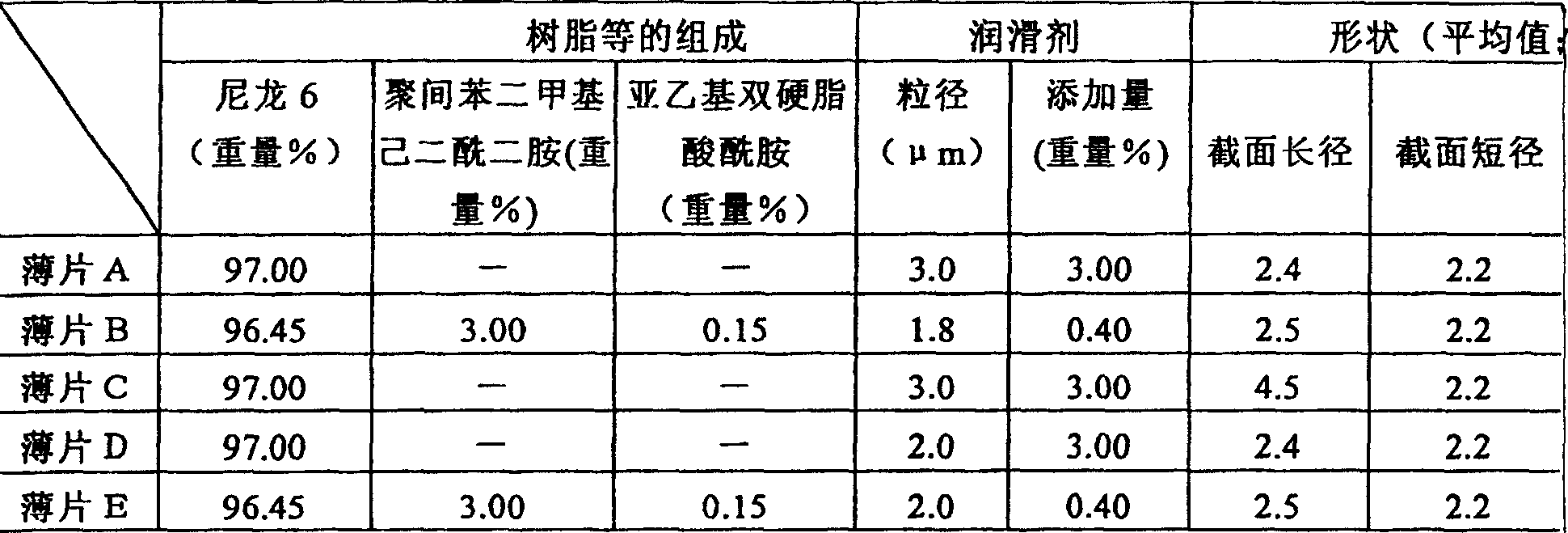

[0124] The above flakes A and B were pre-dried while raising the temperature to about 120° C. with a 15 kl stirring device over about 8.0 hours. A certain amount of each flake was collected from the blender, and its water content was measured. The water content of flakes A and B were both 800 ppm. In addition, the measurement of the water content was performed using a Karl Fischer moisture meter (MKC-210 manufactured by KYOTO Electronics Co., Ltd.), under the conditions of a sample weight of 1 g and a sample heating temperature of 230°C.

[0125] Then, the flakes in each mixer are continuously supplied to the hopper directly above the extruder respectively by a quantitative screw feeder. In addition, the supply amount of the sheet A was 5.0% by weight, and the supply amount of the sheet B was 95.0% by weight. The hopper had a capacity of 150 kg of raw material flakes, and the discharge of the extruder was 450 kg per hour. In addition, adjust the inclination angle of the hopp...

Embodiment 2

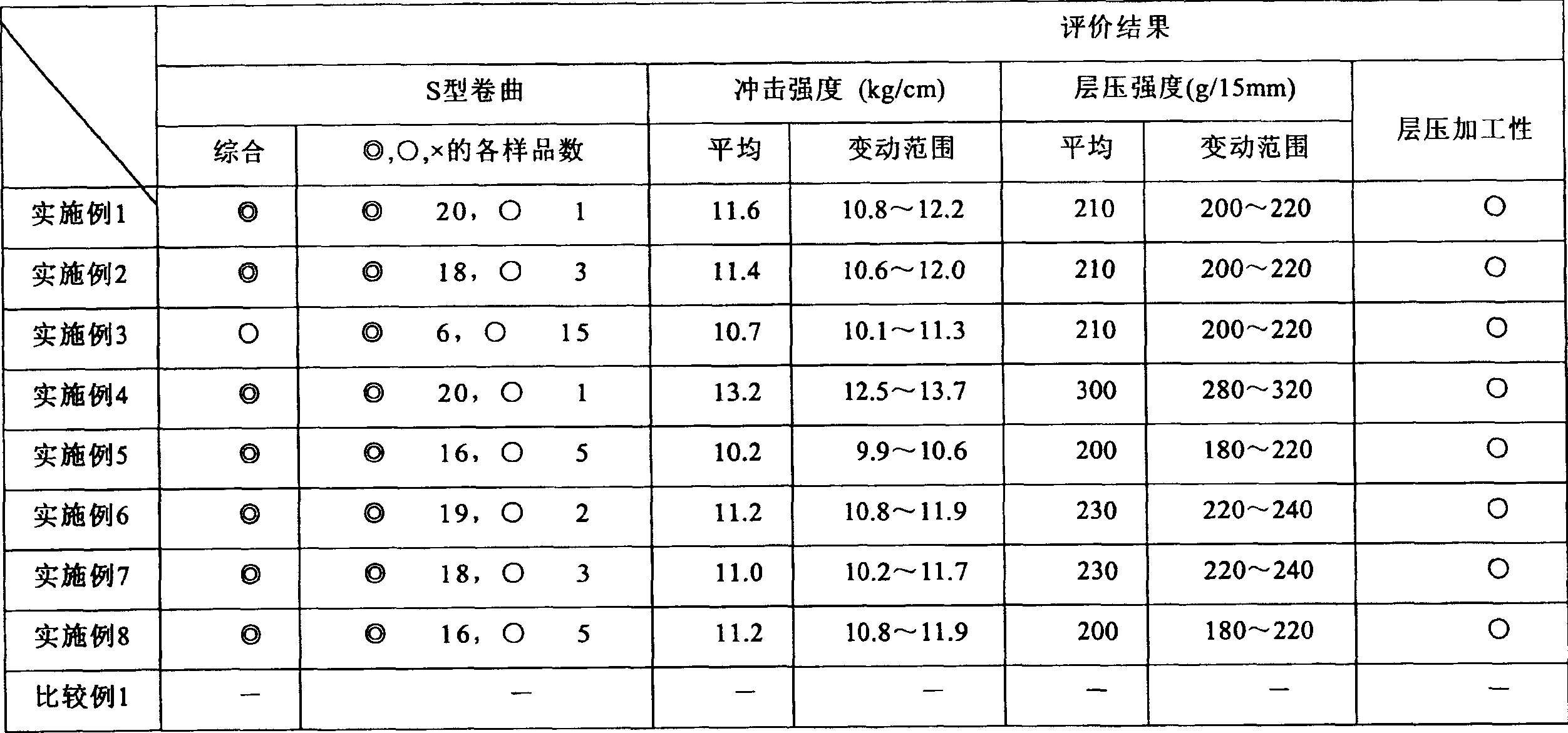

[0153] The polyamide-based resin film of Example 2 was obtained in the same manner as in Example 1, except that the stretching speed of the molten sheet was changed to 75 m / min, and the heat setting temperature after biaxial stretching was changed to approximately 216°C. roll. Then, the properties of the obtained film roll were evaluated by the same method as in Example 1. The evaluation results are shown in Tables 4-8.

Embodiment 3

[0155] After the unstretched film obtained by the same method as in Example 1 is stretched (the first longitudinal stretch) to about 2.2 times with a roll made of Teflon at a stretching temperature of about 90° C., the roll is stretched at about 70 with a roll made of ceramics. Lengthwise stretching (second longitudinal stretching) at about 1.5 times at °C. Furthermore, in the same manner as in Example 1, the longitudinally stretched sheet was continuously introduced into a tenter, stretched horizontally to approximately 4.0 times at approximately 130° C., heat-set at approximately 213° C., and cooled after performing a 5% transverse relaxation treatment. , by cutting both edge portions, continuous film formation to produce a biaxially stretched film of about 15 μm over 2000 m. In addition, the range of change in the surface temperature of the film during the continuous production of the film was the same as in Example 1. The polyamide-based resin film roll of Example 3 was o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com