Series-parallel multi-stage compounding apparatus and method for producing hydrogen by biomass continceous fermentation

A biomass fermentation and composite device technology, which is applied in the field of hydrogen production by immobilized microorganisms fermenting biomass, can solve the problems that the high efficiency and stability of hydrogen production cannot be well achieved, and achieve stable and sustainable gas production. More, the effect of high hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

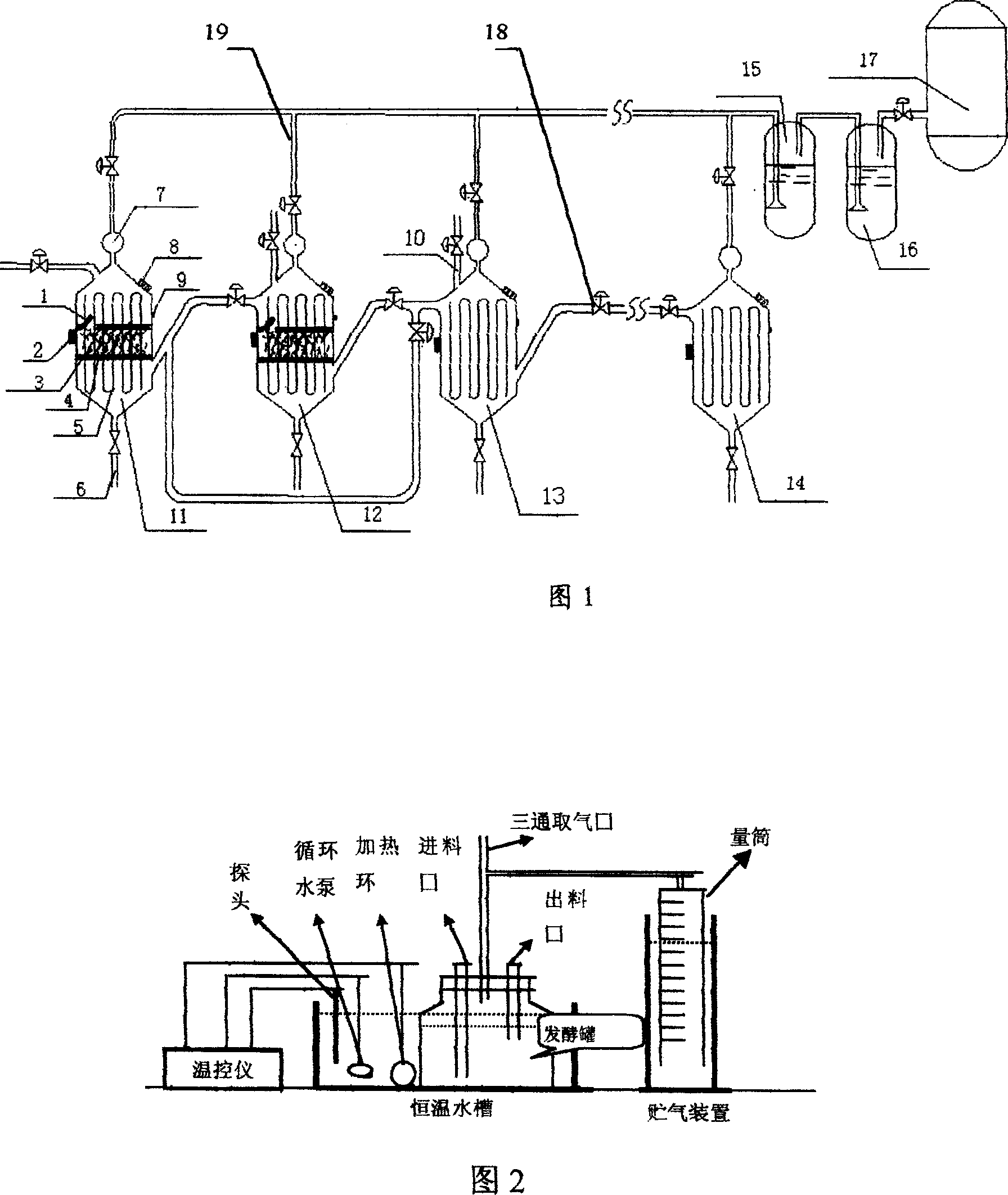

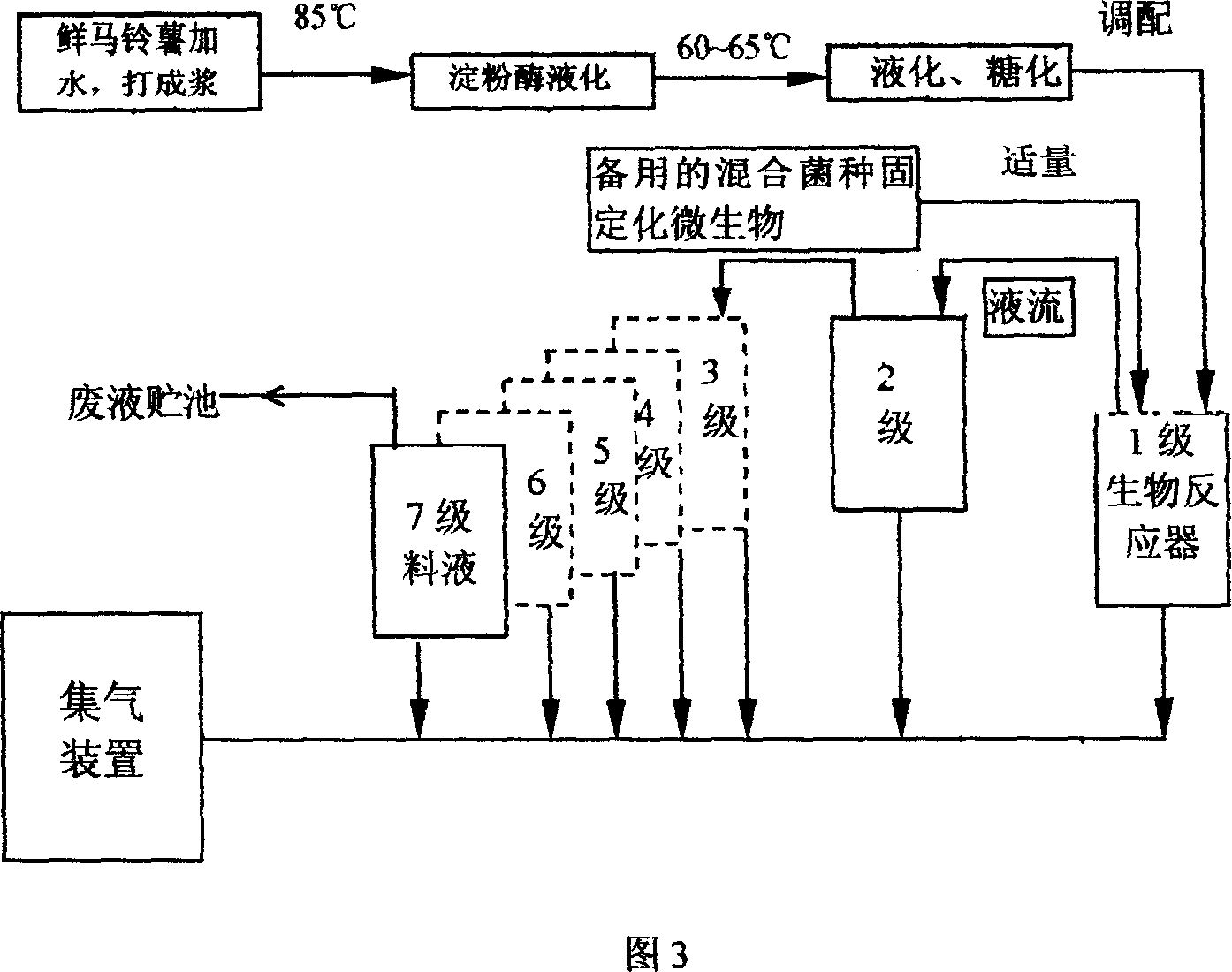

[0049] In Figures 1 and 2, a 1L experimental fermentation hydrogen production fermenter device is used to connect 7 stages of fermenters in series, and only 50-100g of mixed strains of immobilized microbial blocks are put into the first stage. No immobilized microbial blocks are put into the other stages of fermentation hydrogen production fermenters connected in series. Regularly and quantitatively add potato hydrolyzate from the first-stage feed port, suck out the same volume from the second-stage feed port, and then operate in sequence to the last stage to produce hydrogen by fermentation. At each level, the gas volume, hydrogen content, and sampling analysis related indicators and dehydrogenase enzyme activity are measured respectively.

[0050] Level 1, investigation of the ability of mixed strains to immobilize microbial provenance

[0051] From the first 14h of starting, the dehydrogenase activity is at a relatively high level, and at this time hydrogen is hardly produ...

Embodiment 2

[0053] Example 2: After the single-batch investigation of one fermentation cycle of the first-level provenance meets the expected requirements, the continuous fermentation hydrogen production with multi-stage fermentation tanks connected in series using potato hydrolyzate as raw material was formally started.

[0054] Among Fig. 1, 3, the 1st stage (11) is the fermenter that the provenance is cultivated and fermented concurrently, and the 2nd stage (12) is the auxiliary fermenter that the provenance is cultivated and fermented concurrently. The two-stage fermentation tank uses steel bars with a diameter ≥ 1.5 cm, and welds two upper and lower screen plates with a criss-cross interval of about 10 cm. The plates are respectively set at about 1 / 3 of the height of the tank body. Between the two plates is the space for the immobilized microbial strain block of mixed strains. There is a 90cm square hole on the upper plate for putting in and taking out the immobilized block.

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com