Energy-saving gasification furnace for preparing gas from biomass

A gasifier and biomass technology, which is applied in the field of biomass gas production and energy-saving gasifier, can solve the problems of short corrosion life, uneven oxygen supply, low gas volume, etc., and achieve non-corrosion service life and stable firepower combustion. , the effect of high gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

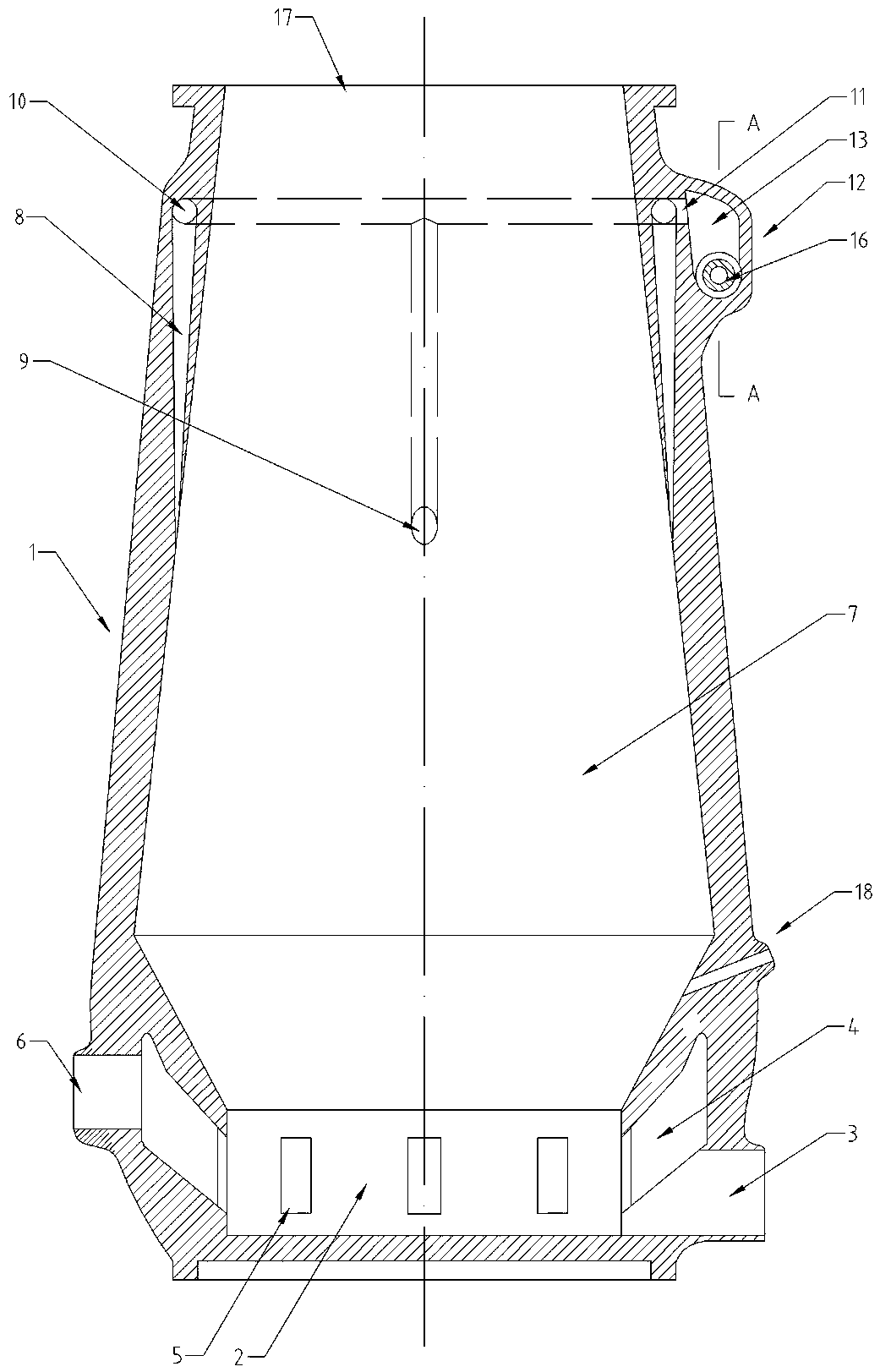

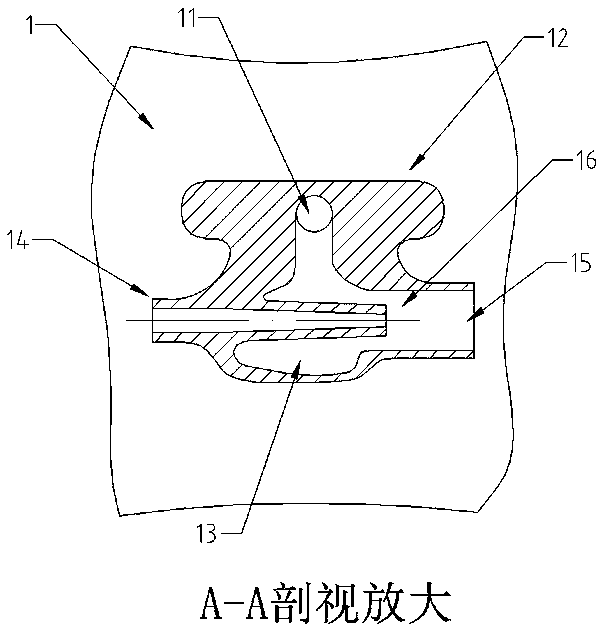

[0014] Refer to attached figure 1 It is an energy-saving gasification furnace for biomass gas production. It is composed of a feed port 17, a furnace and a furnace bottom. The furnace body 1 is integrally sintered with ceramic materials; the inner wall of the combustion zone of the furnace 7 is a conical tube with a narrow top and a wide bottom. Body, the furnace bottom at the lower part of the furnace 7 is the bottom of the concave cylinder, the upper end of the furnace body 1 has a feed port 17, and the bottom has a space 2 for installing oxygen distribution components and an ash storage ignition outlet 3; the furnace in the space 2 There is an annular oxygen supply preheating channel 4 in the body 1 side, and five wall holes 5 are distributed along the inner wall of the annular oxygen supply preheating channel to communicate with the space 2, and there is an external fan on the outside of the annular oxygen supply preheating channel 4 The air inlet 6; the lower side of the ...

Embodiment 2

[0016] This embodiment is an energy-saving gasification furnace for biomass gas production, which is composed of a feed port 17, a furnace and a furnace bottom. The furnace body 1 is sintered and formed with tile and mud materials; the body wall of the furnace body 1 is a sealed annular interlayer cavity used as a water heater Use, the inwall of interlayer cavity is furnace 7, and the outer layer of interlayer cavity has water inlet and water outlet. The inner wall of the combustion zone of the furnace 7 is a conical cylinder with a narrow top and a wide bottom. The bottom of the lower part of the furnace 7 is the bottom of the concave cylinder. The upper end of the furnace body 1 is opened with a feed port 17, and an oxygen supply distribution part is installed at the bottom. There is an annular oxygen supply preheating channel 4 in the furnace body 1 side of the space 2, and six wall holes 5 are distributed along the inner wall of the annular oxygen supply preheating channel ...

Embodiment 3

[0018] This implementation is an energy-saving gasification furnace for biomass gas production, which is composed of a feed port 17, a furnace and a furnace bottom. The furnace body 1 is integrally sintered and formed with earth materials; The bottom of the furnace is the bottom of the concave cylinder. The upper end of the furnace body 1 has a feed port 17, and the bottom has a space 2 for installing oxygen distribution components and an ash storage ignition outlet 3; there is a furnace body 1 side of the space 2 Annular oxygen supply preheating channel 4, the annular oxygen supply preheating channel is distributed with eight wall holes 5 connected with the space 2 along the inner wall, and the outer side of the annular oxygen supply preheating channel 4 has an air inlet 6 for an external fan; There are eight vertical air-receiving passages 8 in the inner wall layer of the furnace 7, the lower end openings of the air-receiving passages 8 are connected to the furnace 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com