Premixed combustion system of diesel engine

A pre-mixed combustion and diesel engine technology, applied to combustion engines, mechanical equipment, machines/engines, etc., to achieve the effects of soft work, lower maximum pressure in the cylinder, and full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

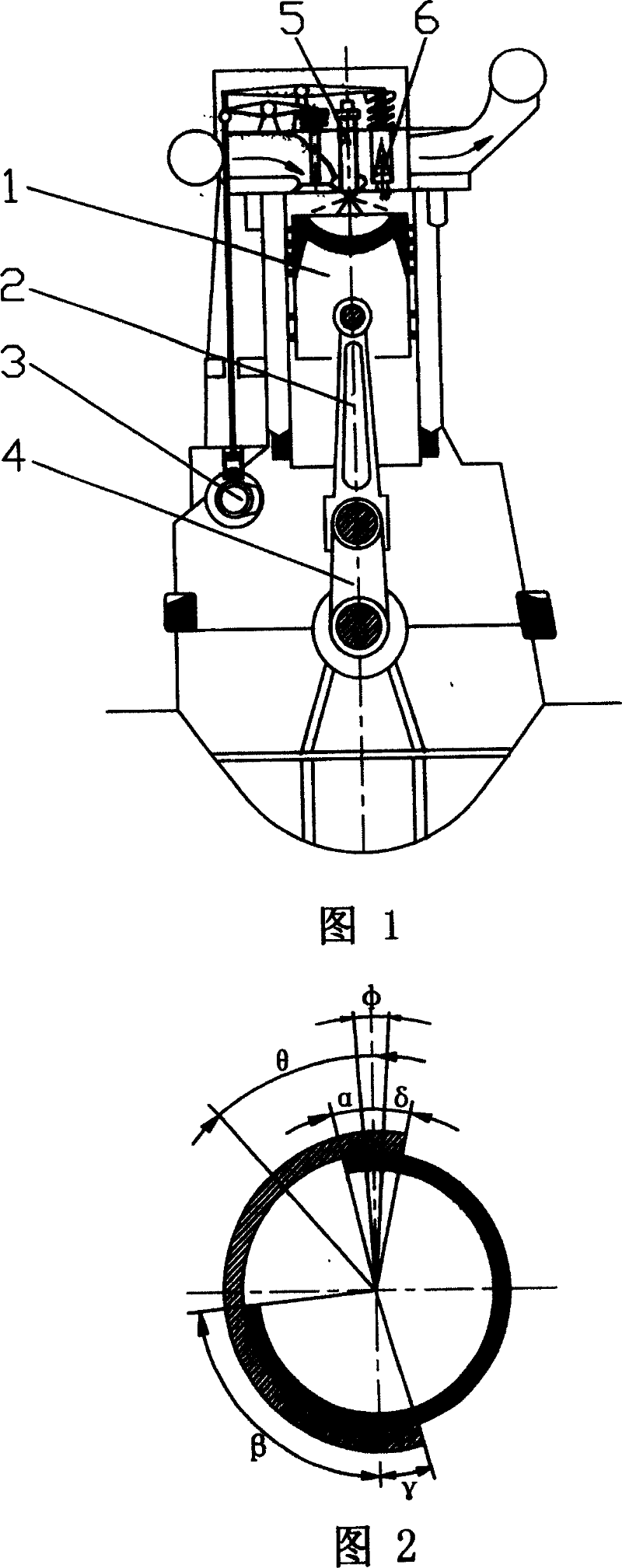

[0011] In the embodiment shown in Figures 1 and 2: the diesel engine adopting premixed combustion in Figure 1 has no obvious difference in structure from the ordinary diesel engine. For example, the piston 1, connecting rod 2 and crankshaft 4 are the main moving parts, and the fixed parts And the major systems have not changed much, but a spark plug 6 is added to the cylinder head, and the intake cam 3 has also become relatively fat. The expansion ratio has been increased from the original 17 to 22. Figure 2 is the fuel supply, ignition and gas distribution phase diagram of the diesel engine shown in Figure 1. Obviously, the diesel engine with premixed combustion has obvious characteristics: the intake delay angle β is 80 degrees crank angle; the geometric fuel supply advance angle θ is 90 degree crank angle; spark plug ignition angle φ is 1 degree crank angle before top dead center. The intake advance angle α, exhaust advance angle γ and exhaust delay angle δ are the same as thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com