Method for industralized prodn. of super fine powder and equipment for crushing super fine powder

A technology for pulverizing equipment and fine powder, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc. Achieve the effect of strong automatic control ability, high efficiency and high technology integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

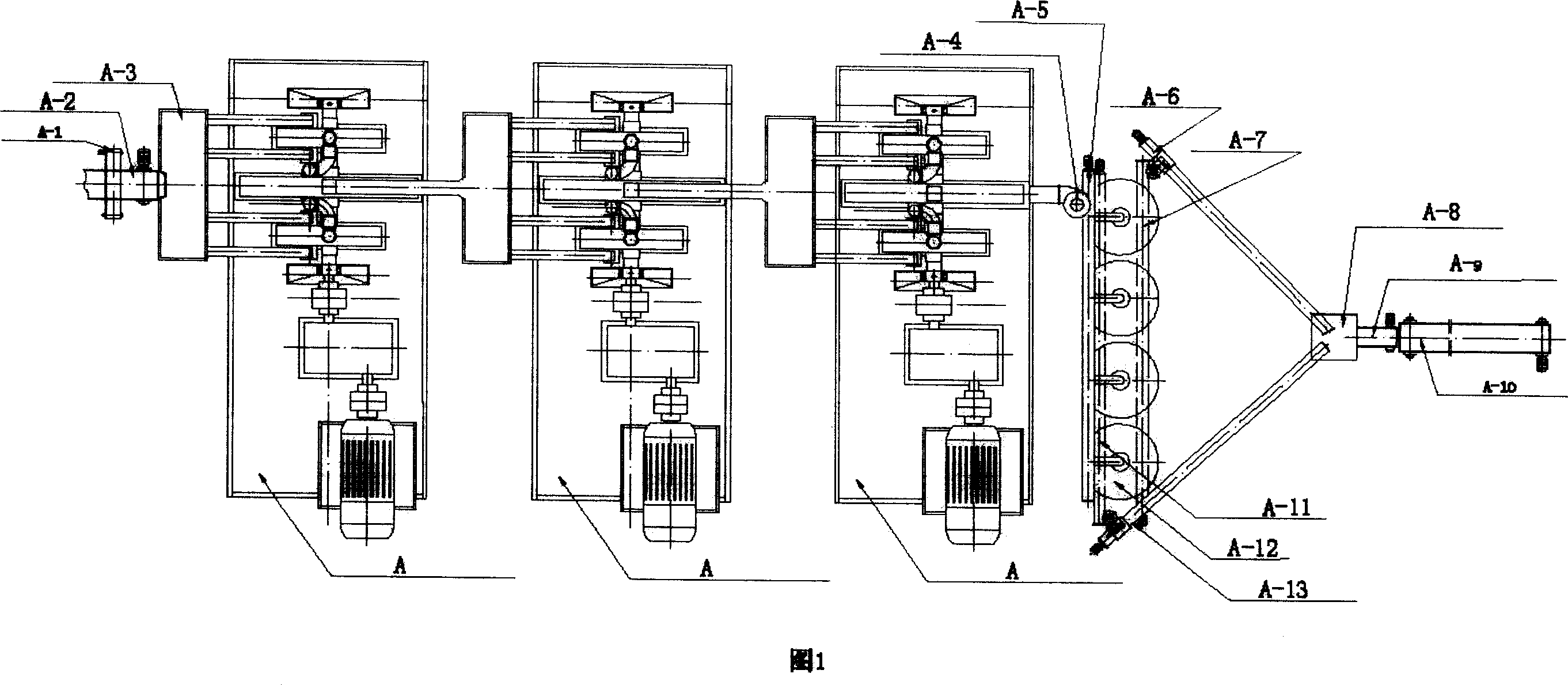

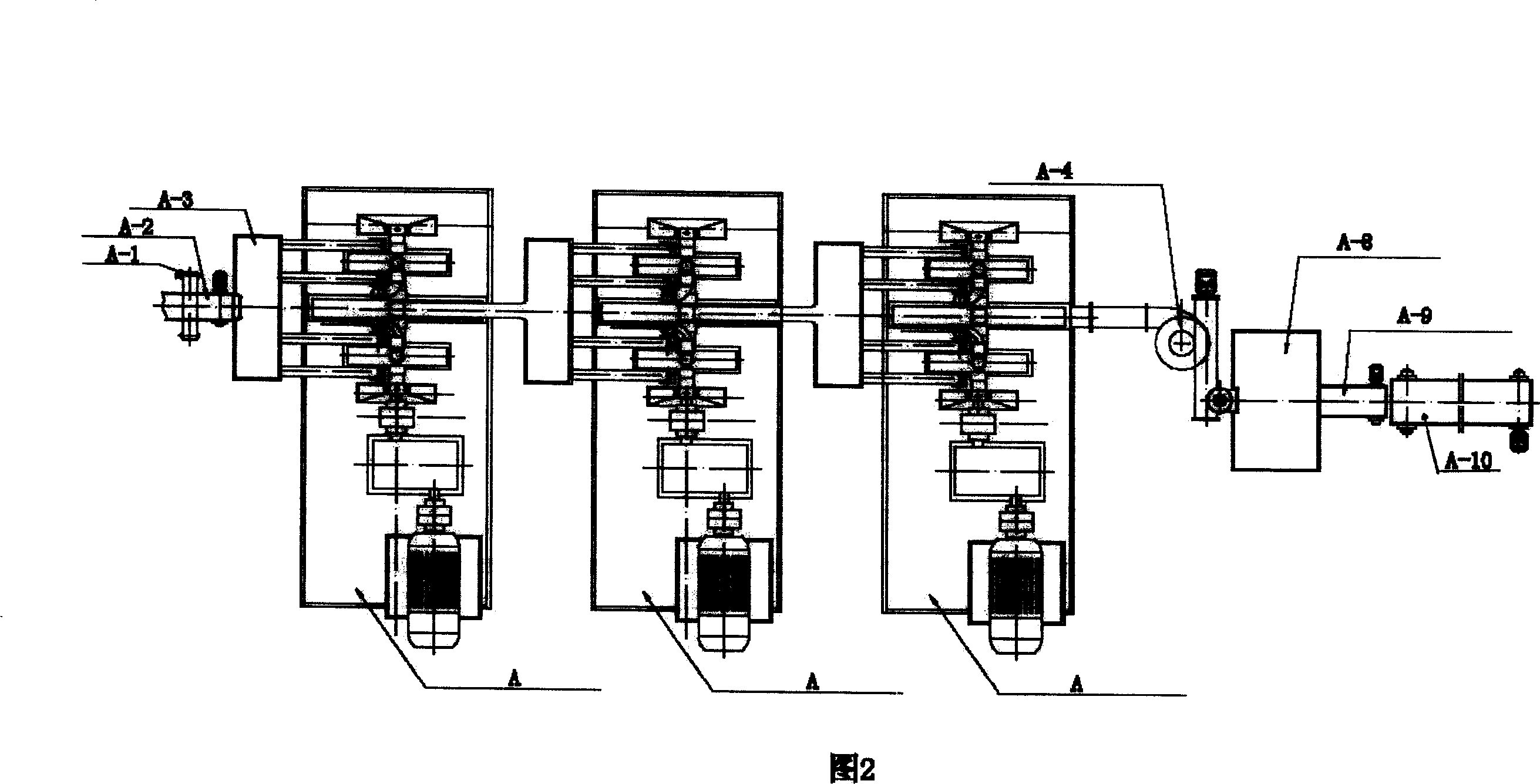

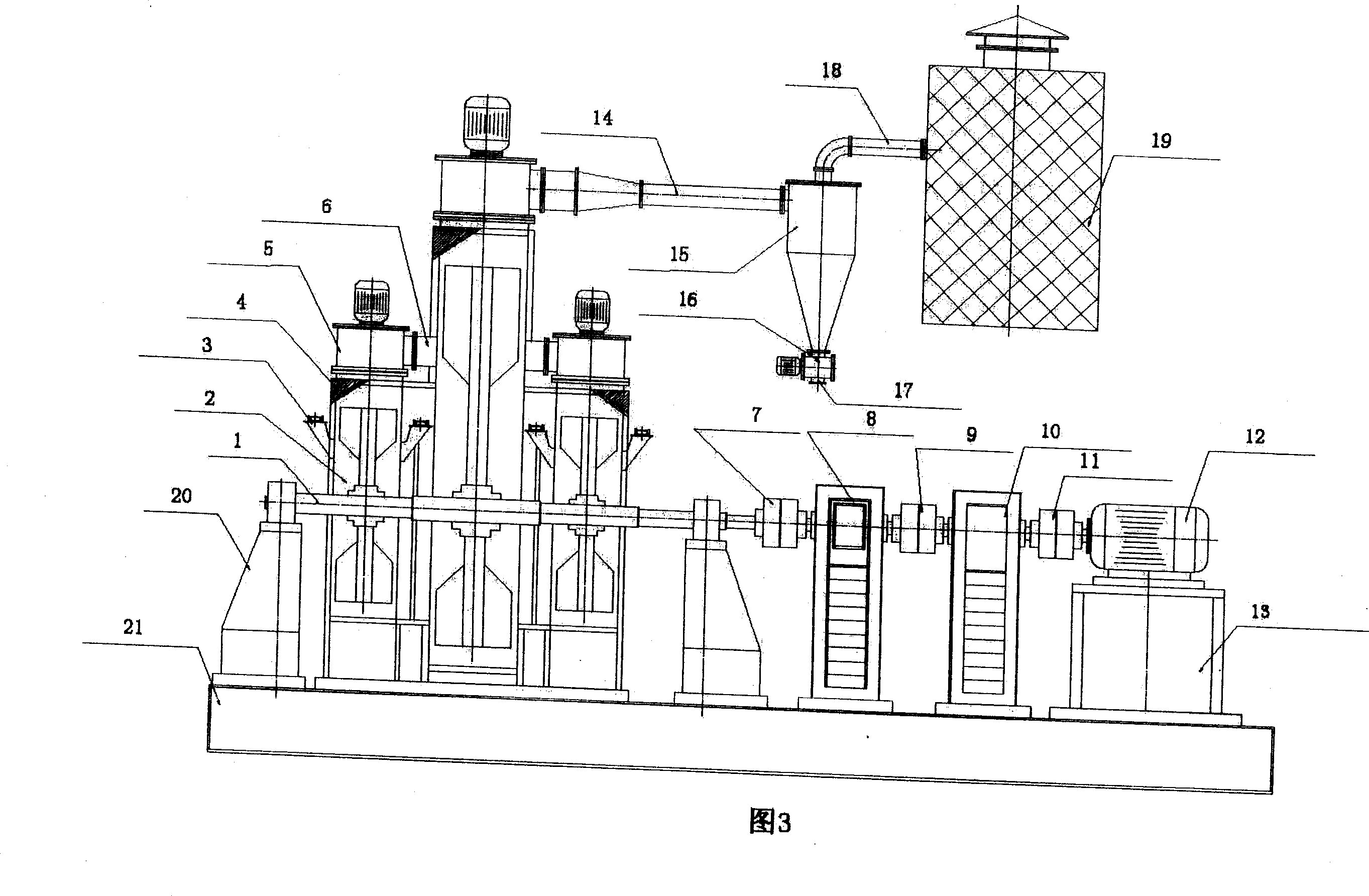

[0049] River sand with a medium Mohs hardness of less than or equal to 3mm is used as a raw material to carry out large-scale industrial production of fine powder according to the process flow and feature (2) of the above schematic diagram 1.

[0050] The raw material enters the micro-opening material box A-3 from the raw material conveyor A-2, and the iron remover A-1 is installed on the raw material conveyor to remove iron. After the raw material enters the micro-opening material box A-3, it is automatically processed The flow fine pulverizer A sucks and pulverizes, and automatically feeds the pulverized material into the micro-opening material box of the secondary flow fine pulverizer A, and is automatically sucked and pulverized by the secondary flow fine pulverizer A, and automatically puts The pulverized material is input into the micro-opening material box of the three-stage follow-up fine grinder A, and is automatically sucked and crushed by the three-stage follow-up fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com