Method for depriving arsenic fluorin phosphoric acid from tail gas of yellow phosphorus

A yellow phosphorus tail gas and removal technology is applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

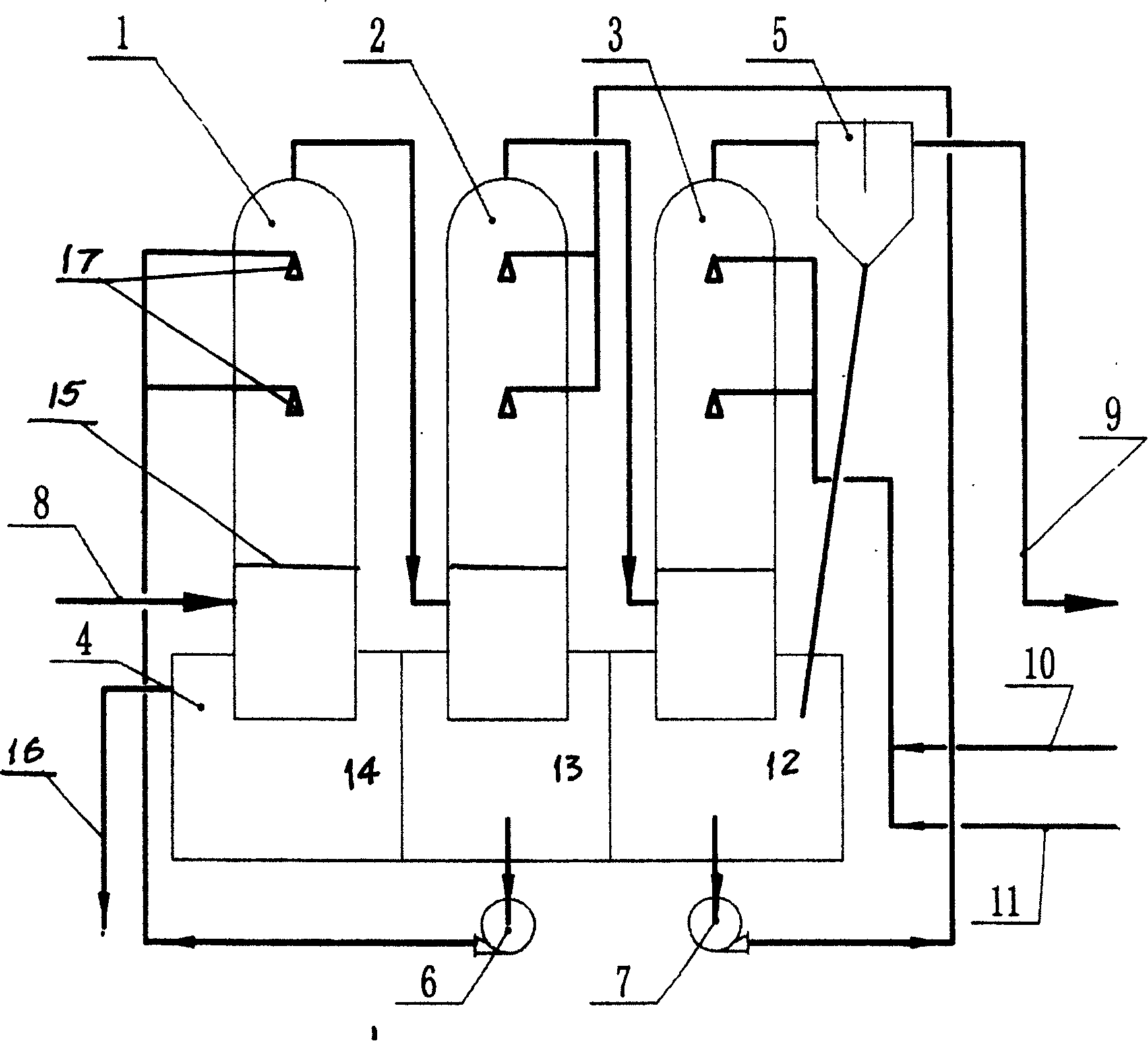

Image

Examples

Embodiment 1

[0035] Embodiment 1. Take the yellow phosphorus tail gas production methanol as an example after purification

[0036] The composition and impurity content of yellow phosphorus tail gas are as follows:

[0037] Yellow phosphorus tail gas

Element

CO

CO 2

N 2

H 2

CH 4

O 2

Volume ratio

85~92%

2~4%

1~3%

4~5%

0.4%

1.0%

[0038]The impurity content of yellow phosphorus tail gas:

[0039] Impurities

As

SiF 4

Total P

h 2 S

Concentration (mg / L)

1.8

450

800

1150

[0040] Yellow phosphorus tail gas volume is 3500Nm 3 / h.

[0041] The lime milk concentration is 10%, the lime milk volume is 55 liters / h, and the circulating water volume is 20m 3 / h. Circulating water quality is phosphorus -1 <100mg / L, pH value 6-8.

[0042] Absorption tower: φ1800×14000mm, three sets, each equipped with two swirl nozz...

Embodiment 2

[0048] Embodiment 2. Taking the purified yellow phosphorus tail gas power generation as an example

[0049] The composition and impurity content of yellow phosphorus tail gas are as follows:

[0050] Yellow phosphorus tail gas

Element

CO

CO 2

N 2

H 2

CH 4

O 2

Volume ratio

85.4%

2.7%

4.39%

6.48%

0.43%

0.6%

[0051] The impurity content of yellow phosphorus tail gas:

[0052] Element

As

h 2 S

Total P

HF

Concentration (mg / L)

2

1050

1170

370

[0053] Yellow phosphorus tail gas volume is 1750Nm 3 / h.

[0054] The lime milk concentration is 5%, the lime milk volume is 50 liters / h, and the circulating water volume is 10m 3 / h.

[0055] Absorption tower: φ1400×11000mm, three sets, each equipped with two swirl nozzles, and the distance between the nozzles is 4m.

[0056] Circulation canal:...

Embodiment 3

[0061] Embodiment 3. Take the yellow phosphorus tail gas burning boiler as an example after purification

[0062] The composition and impurity content of yellow phosphorus tail gas are as follows:

[0063] Element

CO

CO 2

N 2

O 2

Volume ratio

89.7%

1.6%

7.5%

1.2%

[0064] The impurity content of yellow phosphorus tail gas:

[0065] Element

As

h 2 S

Total P

HF

Concentration (mg / L)

1.8

850

800

400

[0066] Yellow phosphorus tail gas volume is 1050Nm 3 / h.

[0067] The lime milk concentration is 8%, the lime milk volume is 25 liters / h, and the circulating water volume is 6m 3 / h.

[0068] Absorption tower: φ1200×11000mm, three sets, each equipped with two swirl nozzles, and the distance between the nozzles is 4m.

[0069] Circulation canal: 1.6×5.4×1.5m.

[0070] Circulating pump: 3 sets of 40GW9-30, two open and one stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com