Method for treating tail gas in acidolysis main reaction in sulfuric acid method titanium pigment production

A technology for exhaust gas treatment and titanium dioxide, which is applied in the directions of titanium dioxide, separation methods, chemical instruments and methods, etc., can solve the problems of affecting the speed of flue gas emission and increasing system resistance, so as to achieve environmental improvement, small gas volume, and low exhaust temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

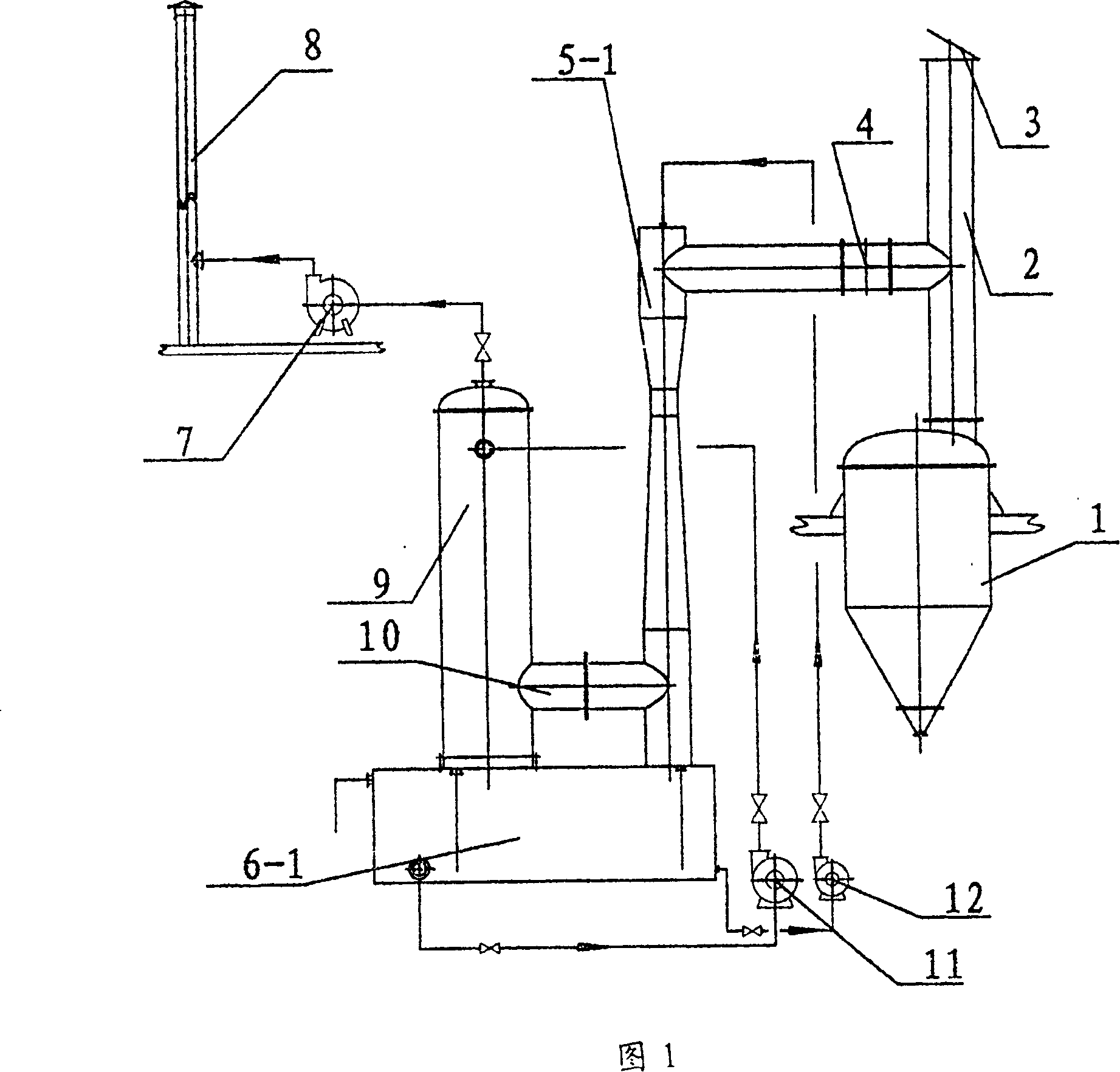

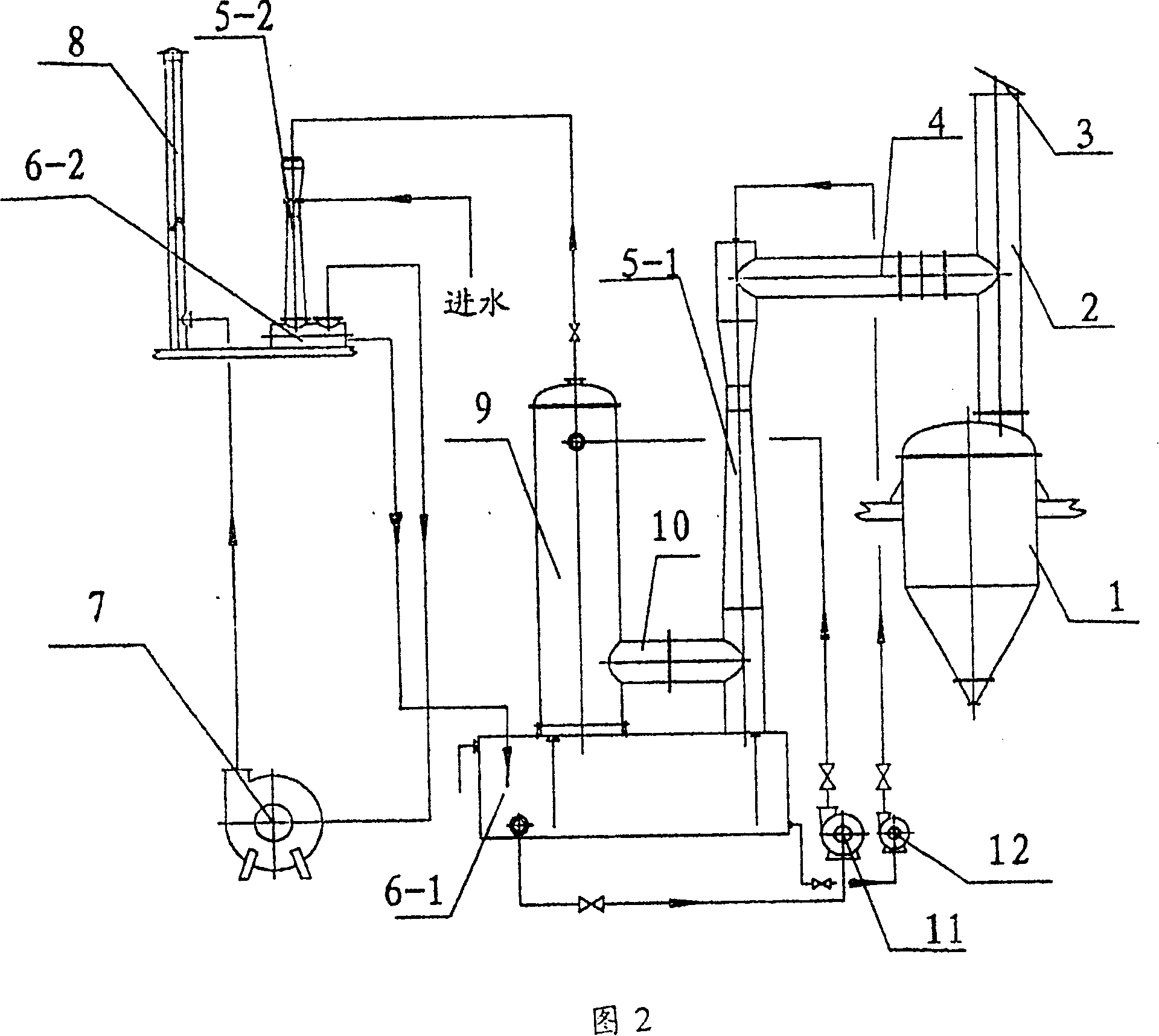

[0017] Below in conjunction with the accompanying drawings describe in detail the implementation of the device for tail gas treatment during the acidolysis main reaction in the production of sulfuric acid titanium dioxide and the device for tail gas treatment during the acidolysis main reaction in a kind of sulfuric acid titanium dioxide production of the present invention, so the present invention The advantages of will become clearer and easier to understand.

[0018] Referring to Fig. 1 and Fig. 2, it can be seen that: a device for treating tail gas during the acidolysis main reaction in the production of sulfuric acid titanium dioxide, it includes an acidolysis tank 1, a chimney 2 with a chimney cover plate 3, and the chimney 2 passes through a chimney pipe and a disc valve 4 lead to the first Venturi tube 5-1, the bottom of the first Venturi tube 5-1 is connected to the circulating pool 6-1, and is connected to the water washing tower 9 through the connecting pipe 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com