Composite structure of diamond surface coated with glass, cubic boron nitride and titanium layers and its manufacturing method

A cubic boron nitride and surface coating technology, which is applied in the direction of surface coating liquid devices, special surfaces, pre-treated surfaces, etc., can solve the problems of low tool life, increased production costs, tool shedding, etc., and achieve volume Effect of enlargement, prevention of early shedding, uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

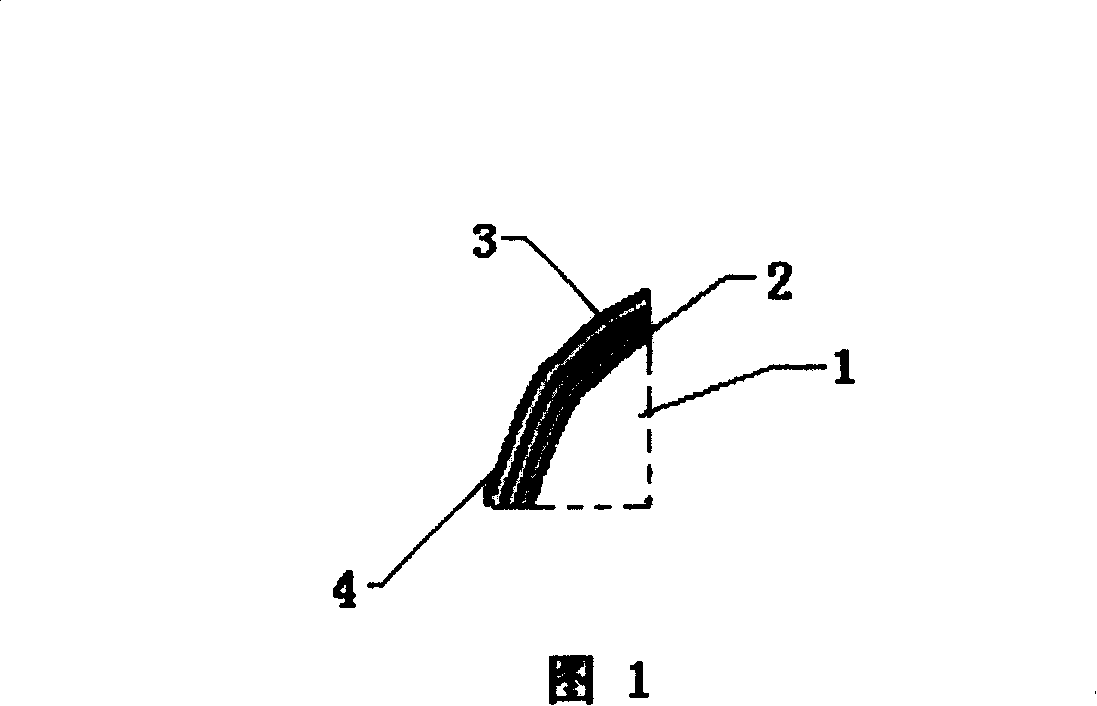

[0011] Embodiment 1: as shown in Figure 1, the present invention is by: a glass layer 2 is arranged on the diamond 1 surface; A cubic boron nitride layer 3 is arranged on the described glass layer 2, and a cubic boron nitride layer 3 surface layer is arranged on the described cubic boron nitride layer 3. Titanium layer 4.

Embodiment 2

[0012] Embodiment 2: Diamond 1 is granular and has an irregular and uneven surface. The glass layer 2, cubic boron nitride layer 3 and titanium layer 4 form a composite according to the irregular and uneven surface of the diamond 1. Layer, wrapping diamond 1.

Embodiment 3

[0013] Embodiment 3: A method for manufacturing a diamond surface-coated glass-coated cubic boron nitride-coated titanium-coated composite structure, the steps of which are as follows:

[0014] Step 1: Coating a layer of glass on the diamond; equipment used: ordinary resistance oven; the steps are as follows;

[0015] Step 1) Put 120g of rosin and 120ml of alcohol in the bottle to completely melt the rosin;

[0016] Step 2) Fully mix the diamond with the above solution at a ratio of 1000CTS / 60ml, then spread it out and let it dry naturally; use glass powder with a particle size 5-6 finer than diamond, for example, the coating particle size is 80 / 100 The diamond of # uses glass powder of 230 / 270~270 / 325#;

[0017] Sodium water glass: Na 20 n. SiO 2 .nH 2 O;

[0018] Step 3) Fully mix the glass powder and diamond with a ratio of 4:1 and pack into a jar;

[0019] Step 4) Preheat the oven to 110°C, put the jar in step 3) into the oven for 2 hours, take it out and cool it;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com