Low pressure double flow spray method and system for high temperature fume quenching and tempering and dust processing

A technology of two-fluid spray and high-temperature flue gas, which is applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve problems that are not involved in flue gas conditioning and cooling, extinguishing high-temperature flue gas sparks, etc., and occupy an area Small area, reduced area, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

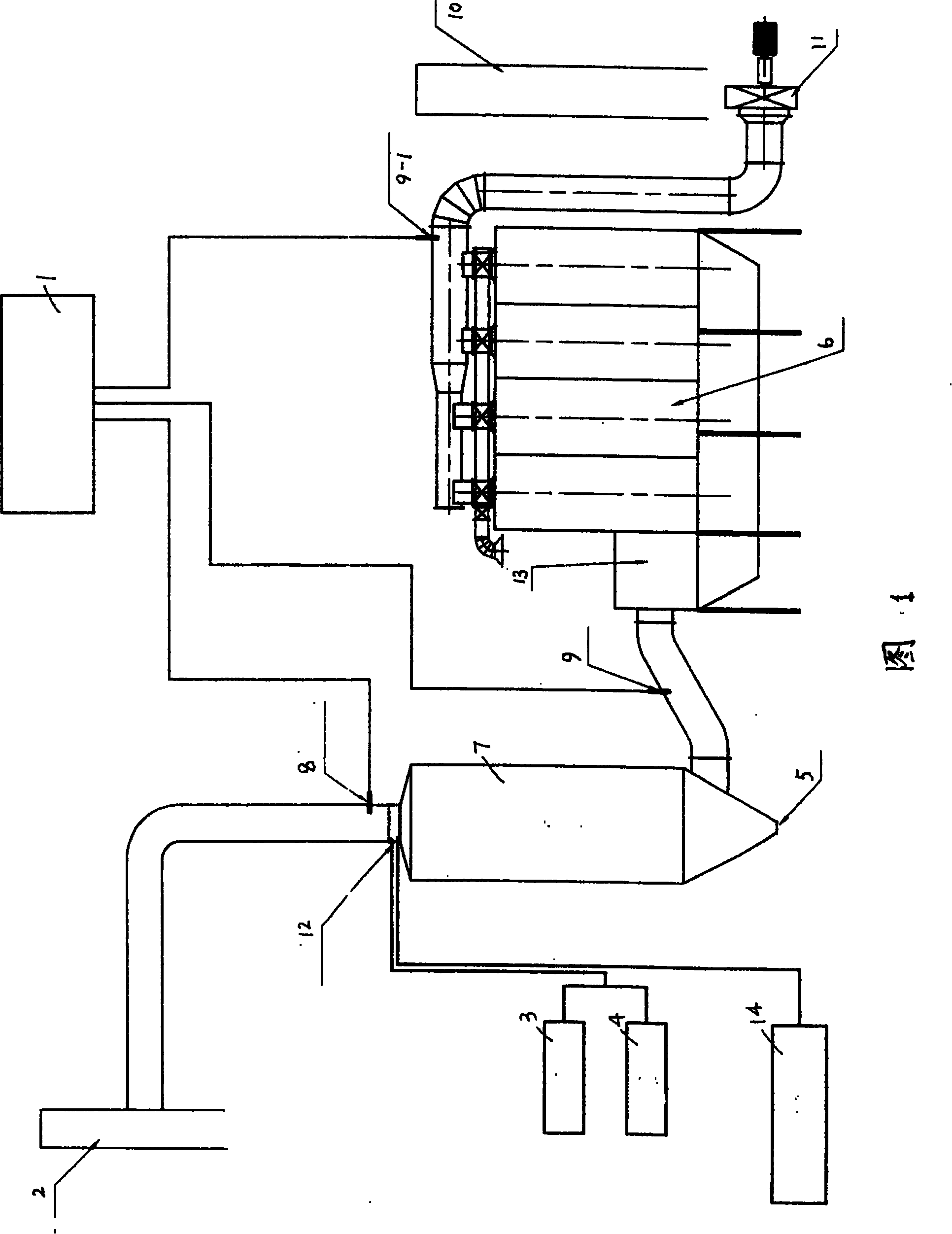

[0019] The high-temperature gas enters the spray tower from the furnace chimney, and a low-pressure dual-fluid nozzle is installed on the upper part of the spray tower. Inside the spray tower, the high-temperature dust-laden gas contacts and mixes with the fine water mist ejected from the nozzle. The effect is completely evaporated, the sparks carried in the high-temperature gas are completely extinguished, and the large particles in the dusty gas are directly discharged through the lower part of the spray tower due to the effect of water mist dedusting, and the cooled dusty gas enters the bag filter through the pipe.

[0020] An air equalization chamber is added at the entrance of the bag dust collection to ensure that the water mist and gas are completely mixed and guide the dusty gas, so that the dusty gas enters each dust removal room evenly, and after being purified by the dust removal function of the bag, it passes through the fan. Exhausted into the atmosphere by the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com