Method of extracting radioactive uranium in fly ash

A technology for radioactive uranium and fly ash, applied in the field of extracting radioactive uranium, can solve problems such as inability to meet demand and shortage of resources, and achieve the effects of shortening project time, improving radioactive pollution, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

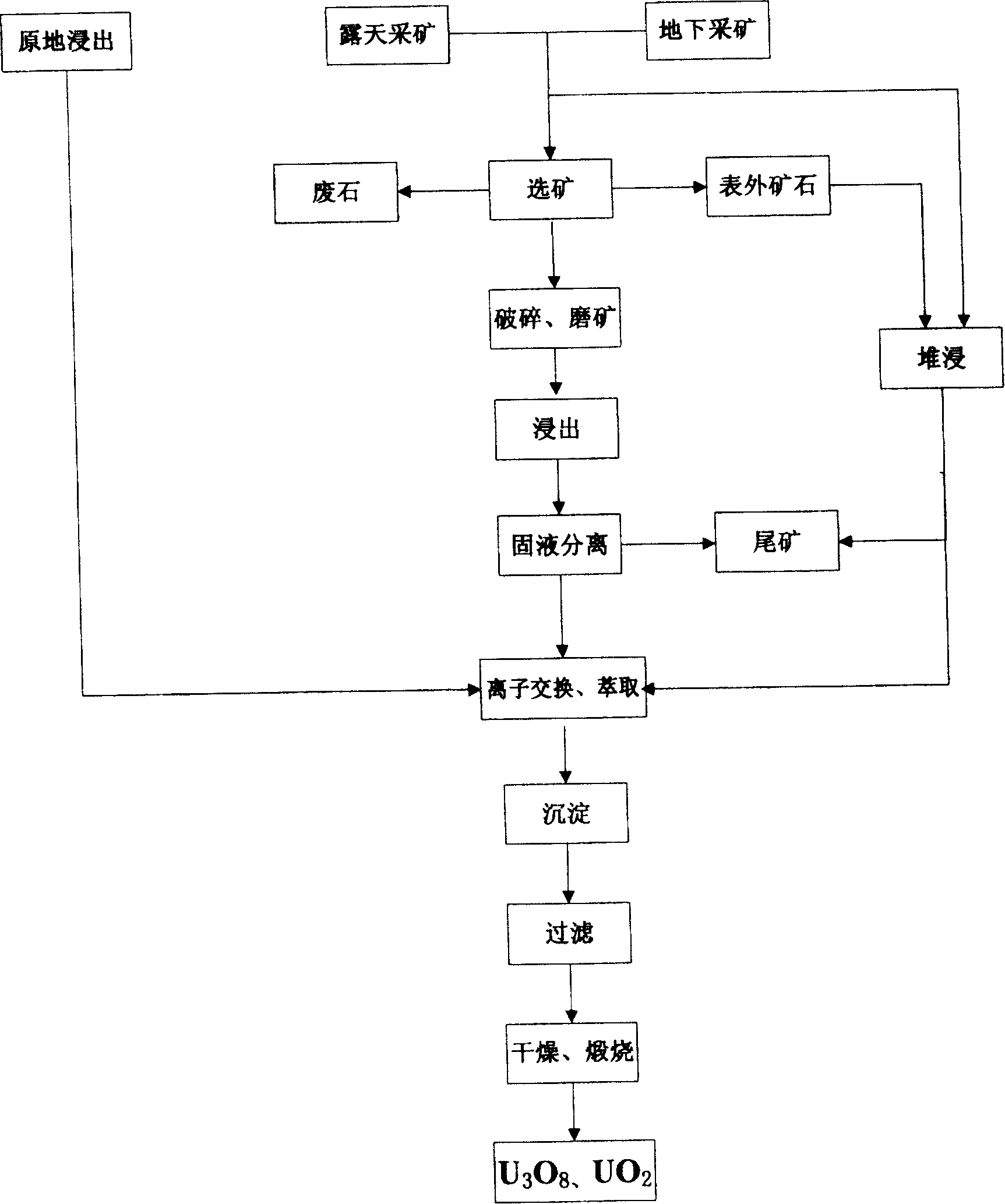

Method used

Image

Examples

Embodiment 1

[0050] Coal contains a certain amount of uranium, most of which exists in the form of solid coal ash after combustion. Most coal combustion processes produce "fly ash" recovered from the gas stream and "bottom ash" extracted from the combustion tunnel. Uranium is distributed in a certain proportion in fly ash and bottom ash. Therefore, the extraction process should involve both forms of coal ash.

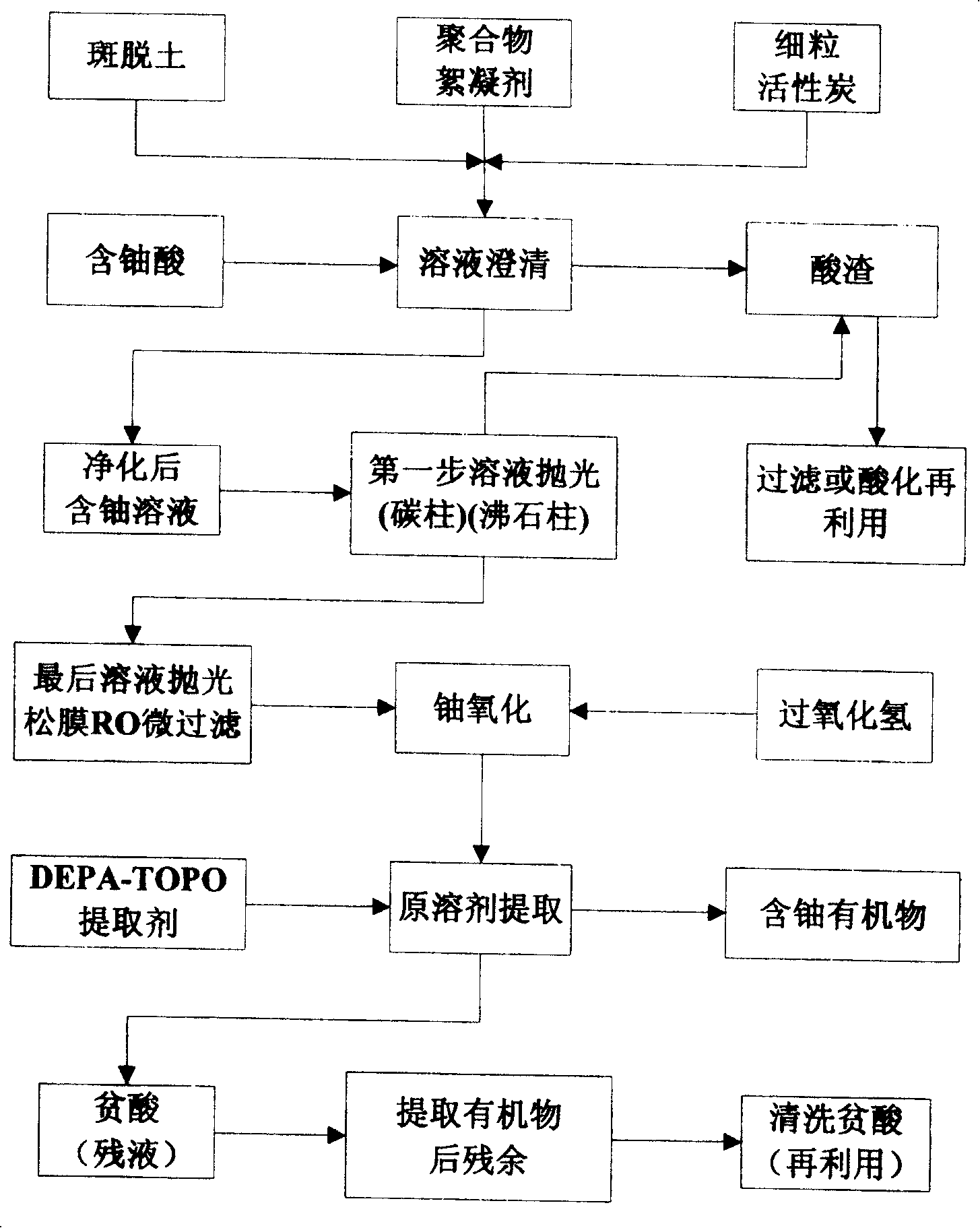

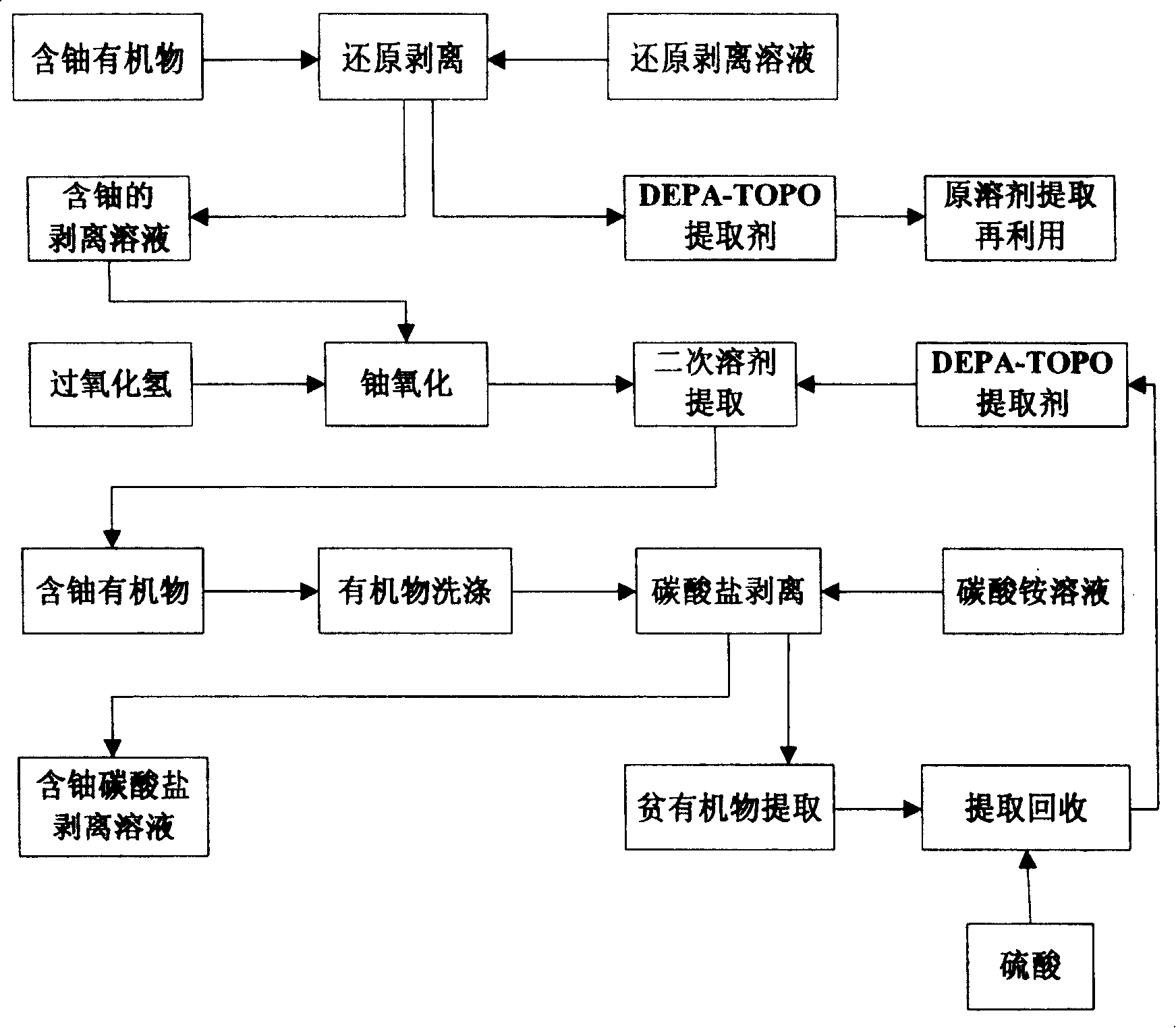

[0051] Extraction of uranium is best performed in a series of reaction tanks containing mineral acids. Sulfuric acid is usually the acid of choice due to its low cost, easy availability and ease of handling. A series of reaction tanks are used in the acid leaching process to optimize the contact time and maximize the dissolution of uranium.

[0052] The acid leached slurry is then washed, usually using countercurrent separation and mixing in a series of tanks, or countercurrent filtration, to maximize uranium recovery and reduce acid and uranium content in the remaining solution....

Embodiment 2

[0054] Example 2 Lignite

[0055] Lignites vary in fuel value, ash content and water content, so some can be used as fuel and others can't. If a lignite can be efficiently burned, the process for extracting uranium from it is similar to that described above for the extraction of uranium from coal. But most lignite has a low fuel composition and cannot be used for electricity or steam. This material is best used for firing to extract uranium, which can be processed in a fluidized bed.

[0056]The burnt lignite is first reacted with medium or weakly acidic solution, and then filtered. Among them, filtration is to purify the solution to extract uranium. The filtered solid is acidified by a strong acid solution, and the acidified solution is poured in reverse, and then filtered. For further processing, neutral or weak acids from the mixing and separation process are recycled back into the starting neutral solution. The acidification process should be carried out at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com