Biodegradable dishware and its producing method

A biodegradable tableware technology, applied in the field of biodegradable tableware and its preparation, can solve the problems of accelerated photooxidation of PP tableware, polymer chain breakage, high product cost, etc., and achieve hygienic performance and physical and mechanical properties. Biodegradation The effect of high degree of investment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

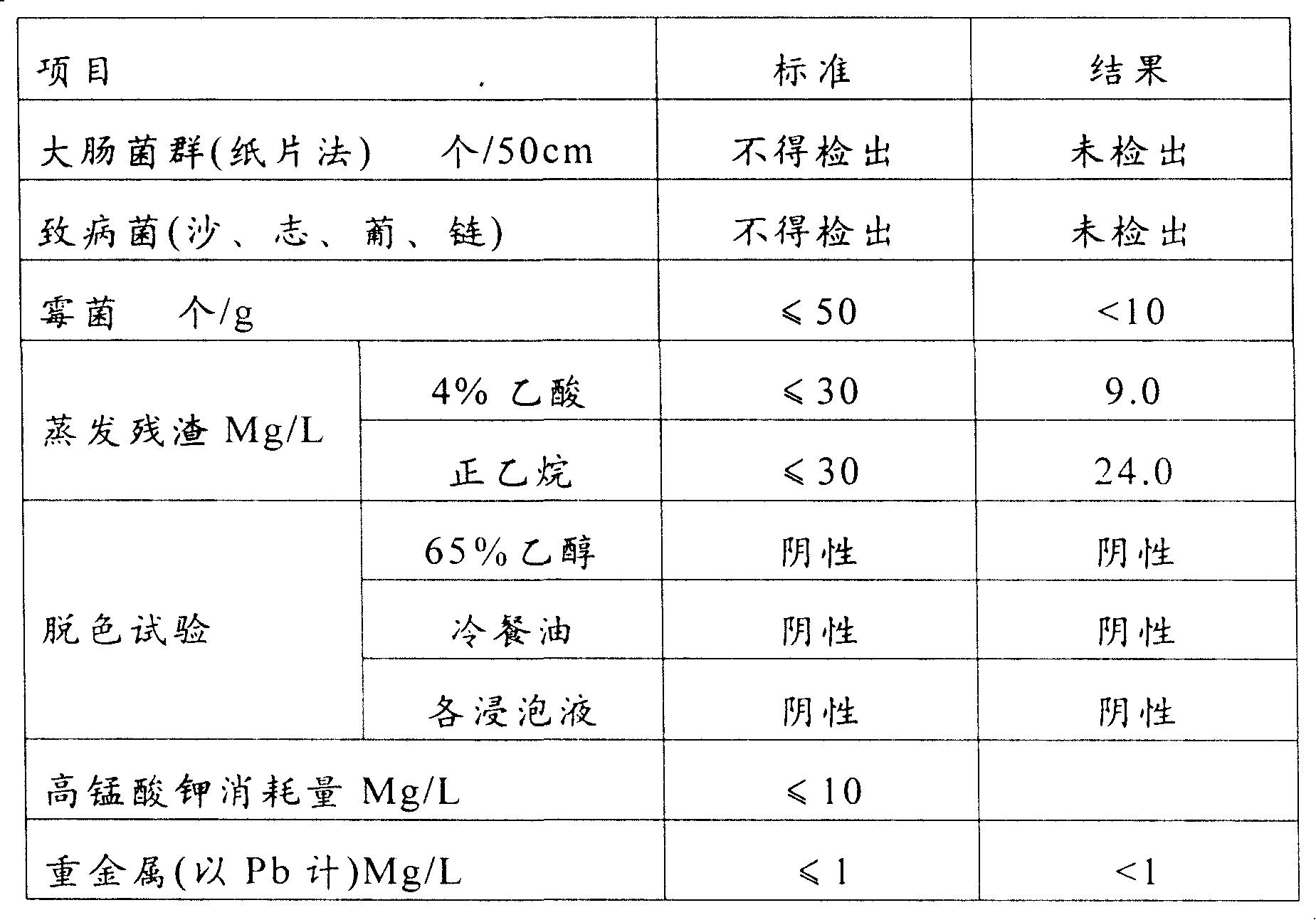

Examples

Embodiment 1

[0025] (1) Weigh 100 parts of biodegradable masterbatch BM1150, 20 parts of resin PP, filler CaCO 3 80 parts, added to a low-speed mixer at normal temperature and stirred for 5 minutes, then added 2 parts of dispersant (liquid paraffin), 2 parts of lubricant (stearic acid), 0.1 part of nucleating agent (sodium benzoate), 5 parts of colorant part, and stirred for 15 minutes to obtain a well-stirred mixture; (2) Send the mixture to the Suhuang HD-200 vertical hopper dryer for drying, which is dried in the form of whirling hot air, and the drying temperature is 120°C. The time is 4 hours, the air volume is 1850 cubic meters per hour, and the air pressure is 1350Pa; (3) Pour the dried mixture into the SJ-80 meshing extrusion with a mixing structure and a compression ratio of 3.5:1. After being plasticized in the machine, it is extruded by the T-die. When extruding, the screw speed of the extruder is 50-80 rpm; (4) The extruded film is immediately transported to the plastic forming...

Embodiment 2

[0027] (1) Weigh 100 parts of biodegradable masterbatch BM1150, 20 parts of resin PP, filler CaCO 3 80 parts, added to a low-speed mixer at normal temperature and stirred for 5 minutes, then added 2 parts of dispersant (liquid paraffin), 2 parts of lubricant (stearic acid), 0.1 part of nucleating agent (sodium benzoate), 5 parts of colorant part, and stirred for 15 minutes to obtain a well-stirred mixture; (2) Send the mixture to the Suhuang HD-200 vertical hopper dryer for drying, which is dried in the form of whirling hot air, and the drying temperature is 120°C. The time is 4 hours, the air volume is 1850 cubic meters per hour, and the wind pressure is 1350Pa; (3) Pour the dried mixture into the SJ-90 meshing extrusion with a mixing structure and a compression ratio of 3.5:1. After being plasticized in the machine, it is extruded by the T die. When extruding, the screw speed of the extruder is 50-80 rpm; (4) The extruded film is calendered by a calender roller and cooled to...

Embodiment 3

[0029] (1) Weigh 100 parts of biodegradable masterbatch PZ7220 and 50 parts of resin PP, add them to a low-speed mixer at room temperature and stir for 5 minutes, then add 2 parts of dispersant (liquid paraffin) and 2 parts of lubricant (stearic acid) in sequence 1 part, 0.1 part of nucleating agent (sodium benzoate), 5 parts of colorant, stirred for 15 minutes to obtain a uniform mixture; The machine is dried by whirling hot air, the drying temperature is 120°C, the drying time is 4 hours, the air volume is 1850 cubic meters per hour, and the wind pressure is 1350Pa; (3) Pour the dried mixture into the screw with a mixing structure, In the SJ-80 meshing extruder with a compression ratio of 3.5:1, it is extruded by a T-die after mastication. When extruding, the screw speed of the extruder is 50-80 rpm; (4) the extruded The diaphragm is immediately transported to the plastic forming machine in the molten state, formed according to the shape of the mold, and demoulded after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com