Epoxy resin composition for semiconductor encapsulation and semiconductor device using the same

An epoxy resin and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as interface peeling and deformation of flip-chip components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6、 comparative example 1~9

[0131] The components shown in the following Tables 1 to 3 were blended according to the ratios shown in the tables, and melted and kneaded for 3 minutes in a twin-roll kneader (temperature 100° C.). Next, after the molten material is cooled, it is pulverized to obtain a desired epoxy resin composition for encapsulating a semiconductor. And, "part" means a weight part.

[0132] [Table 1] (parts)

[0133]

[0134] [Table 2] (parts)

[0135]

[0136] [Table 3] (parts)

[0137]

[0138] Using the epoxy resin compositions obtained in these Examples and Comparative Examples, the embedding void resistance and deformation were measured by the following methods, and the pressure cooker retort test (PCT test) was evaluated. The obtained results are collectively shown in Tables 4 to 6 below.

[0139] [Embedding void resistance]

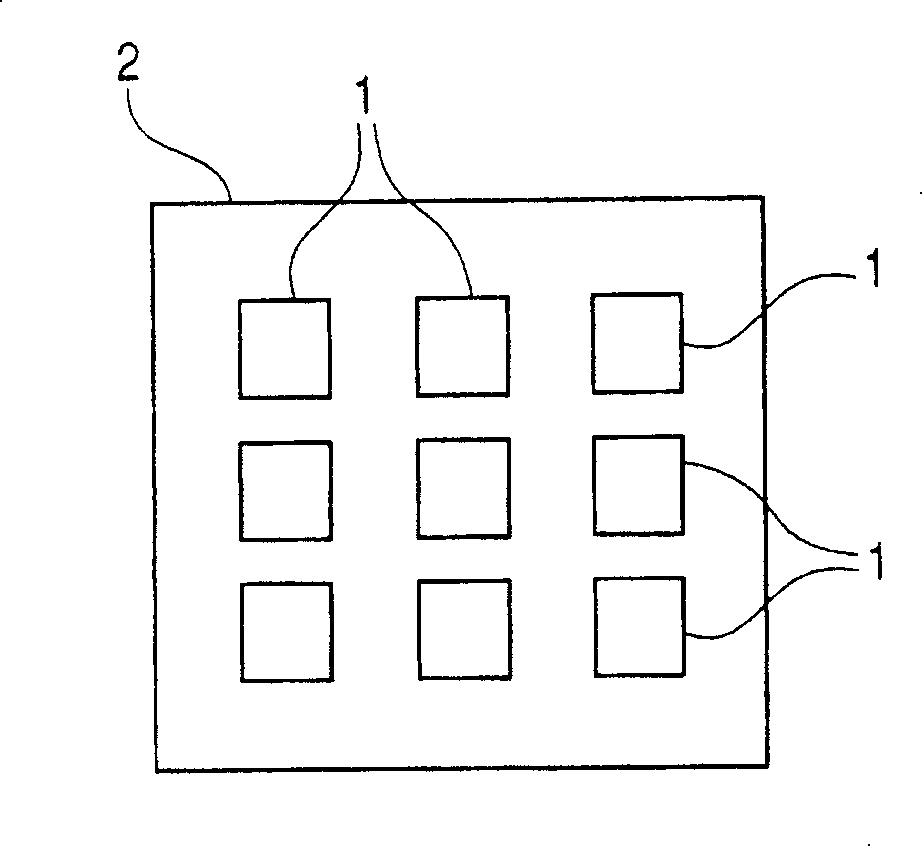

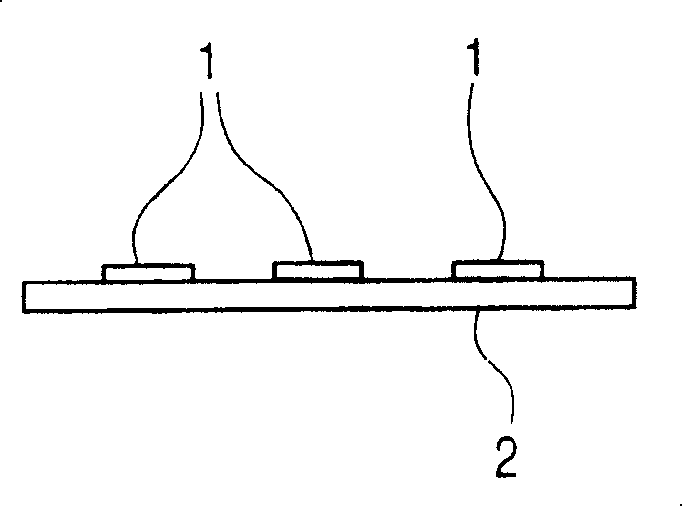

[0140] like Figure 1A and Figure 1B As shown, it is manufactured by mounting nine semiconductor elements 1 (chip size: 10 mm x 10 mm x thickne...

Embodiment 17~32、 comparative example 10~23

[0156] The components shown in the following Tables 7 to 10 were blended according to the ratios shown in the tables, and melt-kneaded for 3 minutes in a twin-roll kneader (at a temperature of 100° C.). Next, after cooling this molten material, it pulverizes, and obtains the desired epoxy resin composition for semiconductor sealing. And, "part" means a weight part.

[0157] [Table 7] (parts)

[0158]

[0159] [Table 8] (parts)

[0160]

[0161] [Table 9] (parts)

[0162]

[0163] [Table 10] (parts)

[0164]

[0165] Using the epoxy resin compositions obtained in these Examples and Comparative Examples, occurrence and deformation of unfilled were measured by the following method, and pressure cooker retort test (PCT test) was evaluated. The obtained results are collectively shown in Tables 11 to 14 below.

[0166] [Fillability and Occurrence of Interfacial Peeling]

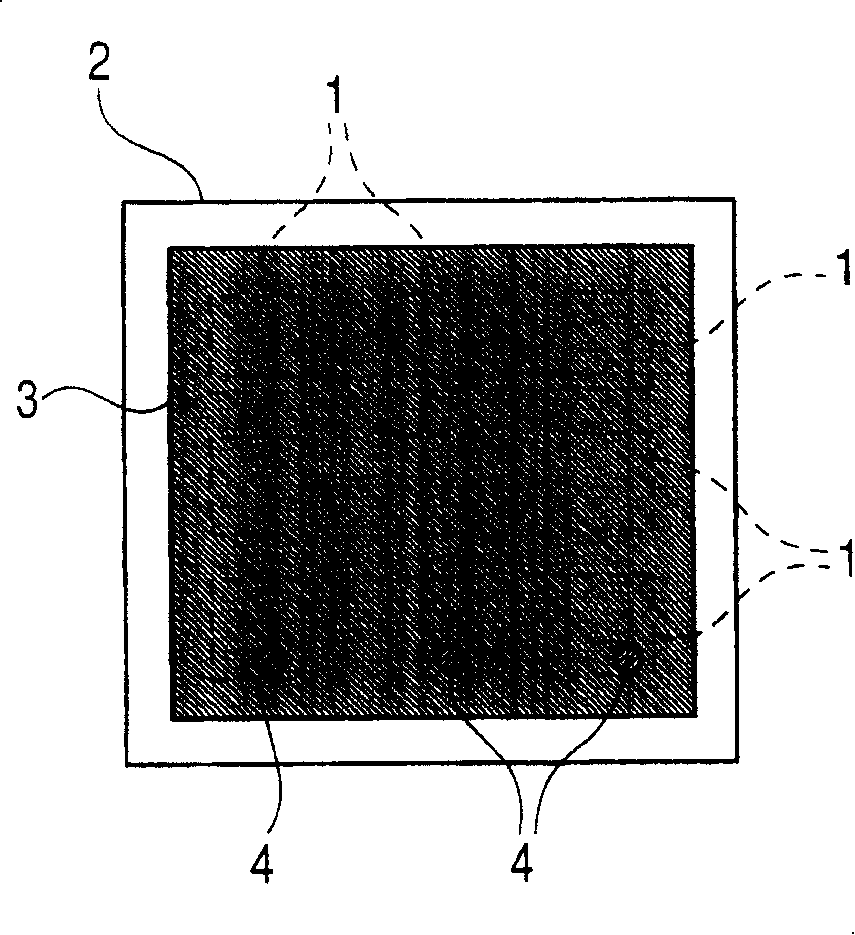

[0167] like Figure 3A and Figure 3B As shown, nine semiconductor elements 5 (chip size: 7mm×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com