Use of rare-earth element in cultivating aerobic particle mud and controlling mud expansion

A technology of aerobic granular sludge and rare earth elements, applied in water/sludge/sewage treatment, rare earth metal compounds, biological water/sewage treatment, etc., can solve the problems of aerobic granular sludge and no in-depth research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The application of the present invention will be further introduced below with specific implementation examples:

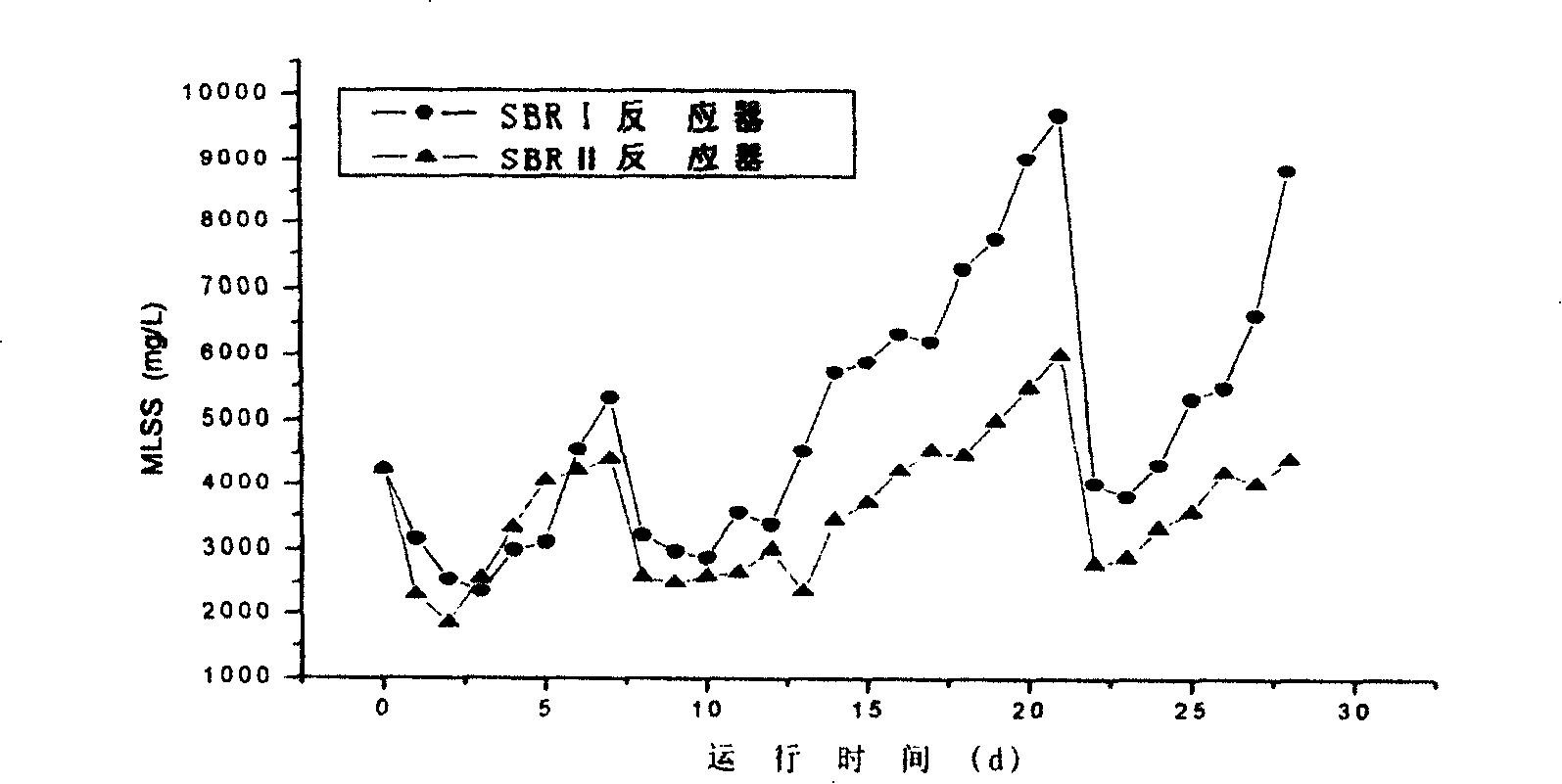

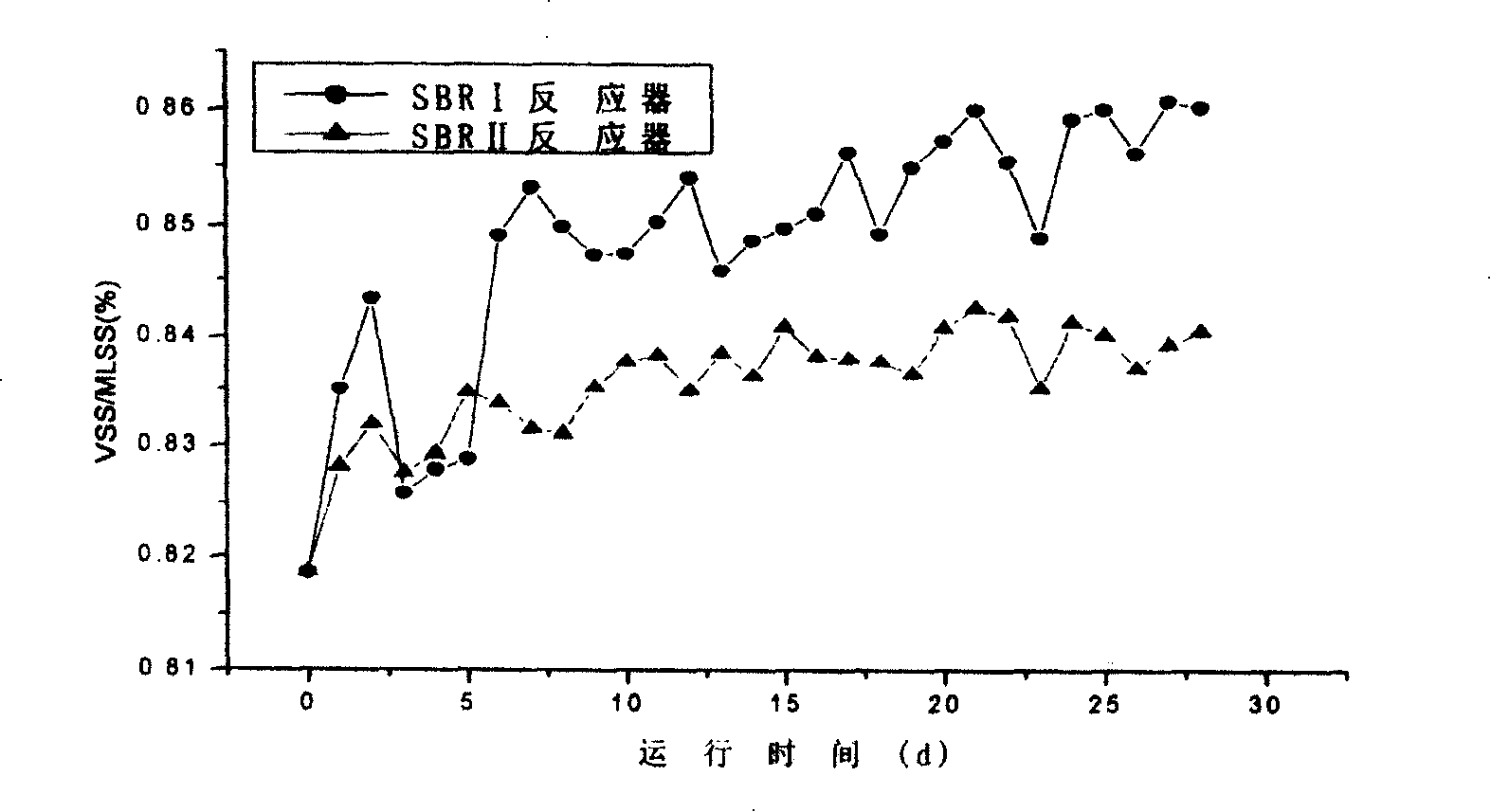

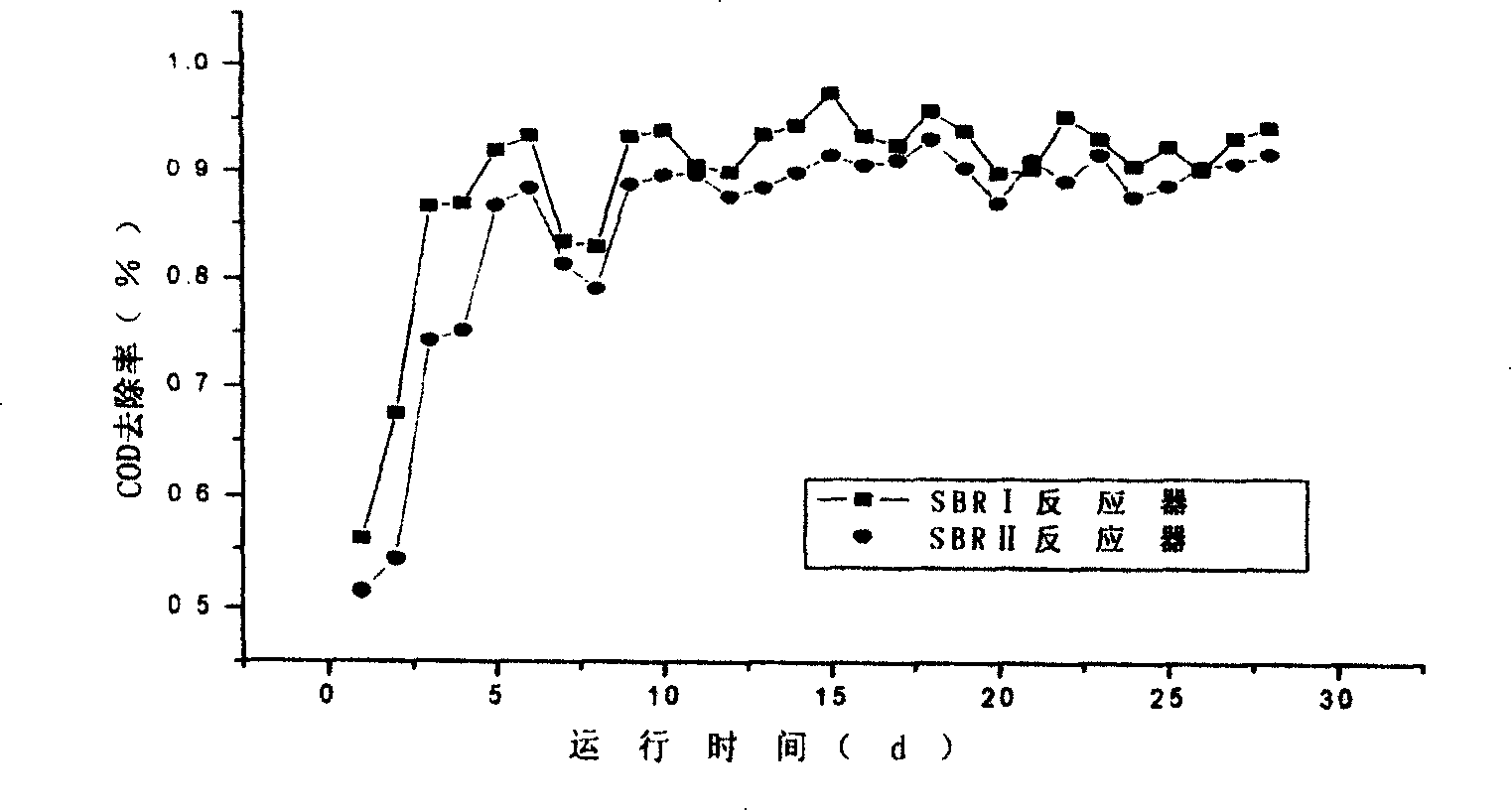

[0029] This example is a specific application of using rare earth elements to cultivate aerobic granular sludge. It takes 28 days from the start of the reactor to the formation of aerobic granular sludge in the reactor. Two reactors run simultaneously, and wherein SBR I reactor starts to add a rare earth element (lanthanum nitrate) solution every 3 days, makes the concentration of rare earth element in the reactor be 30mg / L. The whole process is divided into three operation phases.

[0030] Run Phase 1

[0031] Before inoculation, the activated flocculent sludge is continuously aerated with diluted beer wastewater for 4 days to make the sludge initially domesticated. The activated flocculent sludge is a typical filamentous structure connection, the color is yellowish brown, the structure is loose, and the specific gravity is small. . After the reactor is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com