Cathode flow field plate for self-breathing micro-proton exchange film fuel cell and producing method

A technology of proton exchange membrane and cathode flow field, which is applied in the parts of fuel cells, solid electrolyte fuel cells, fuel cells, etc. Effective utilization, the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

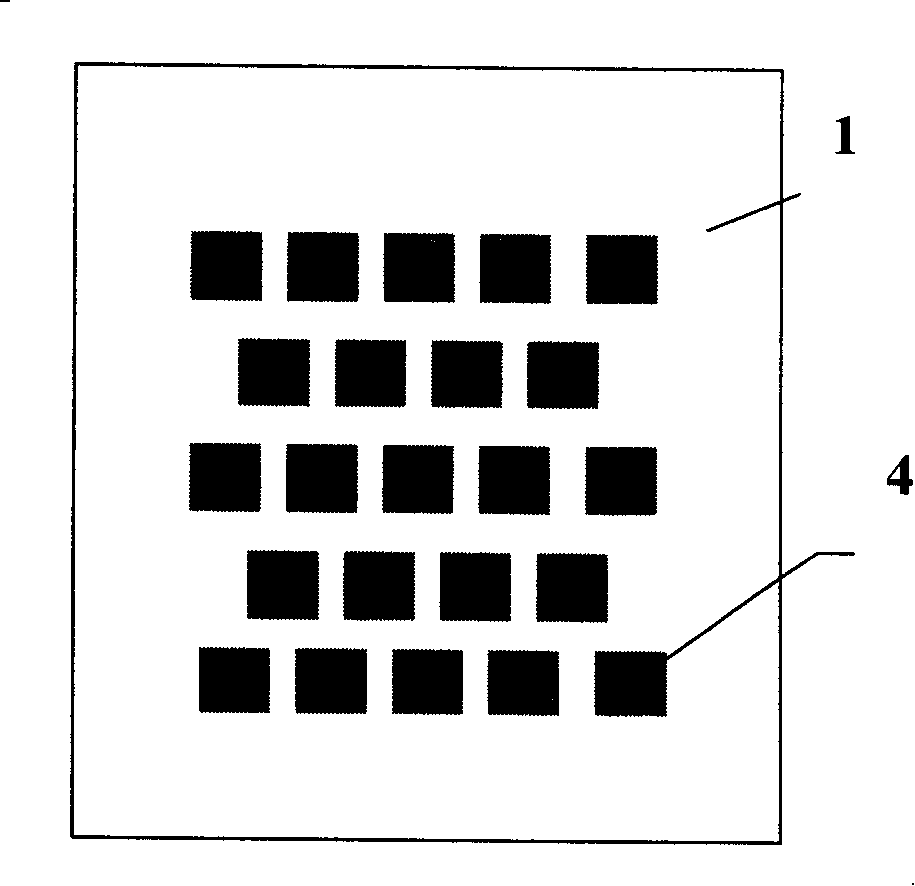

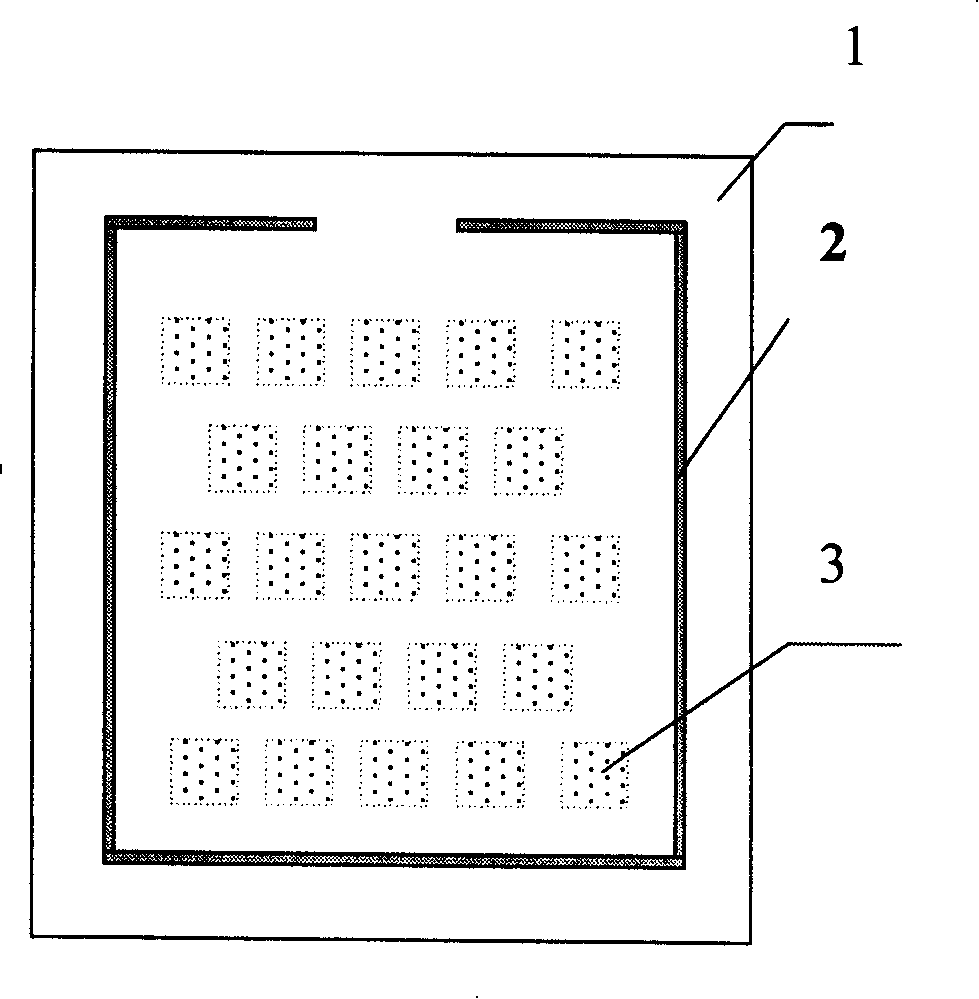

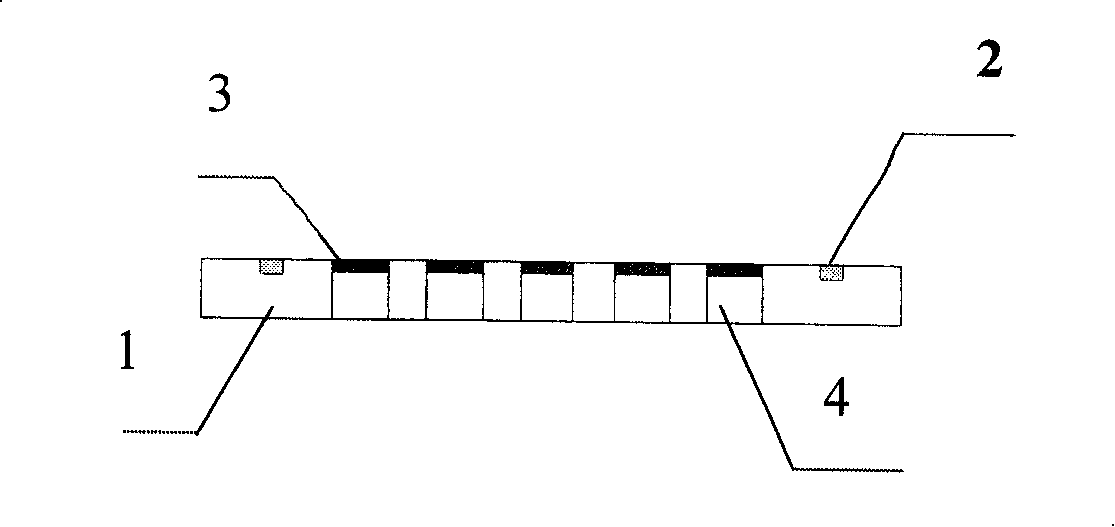

[0036] Select a N(100) silicon wafer with a thickness of 350 μm and a resistivity of less than 15Ω·cm, press Figure 1-3 In the structure shown, both the front and back sides adopt dry etching (DRIE method) to make a cathode double-layer hollow flow field structure with an effective area of 1.2×1.2cm. The duty cycle is 70%; the flow channel near the membrane electrode side is also of equal diameter, with a cross-sectional area of 11 μm×11 μm, a duty cycle of 50%, and a thickness of 60 μm. Figure 4 It is the SEM picture of the prepared cathode structure, wherein (a) is a structural photo of the flow channel on the air side, and (b) is an enlarged photo of the small hole structure corresponding to the back of the air side flow channel (near the MEA side); Figure 5 It is the SEM photo of the cross-section of the structure inclined upward at 30°; a conductive layer is formed on the surface of the micropores of the flow field by physical or chemical methods, ready for use.

...

Embodiment 2

[0041] Select an N(100) silicon wafer with a thickness of 350 μm and a resistivity of less than 15Ω·cm, and adopt the same method as the manufacturing process steps (1)-(4) to form etching windows each with a size of 800 μm×800 μm on the front side of the silicon wafer , using dry etching (DRIE), controlling the etching time, so that a straight hole of equal diameter and 250 μm deep is formed; after cleaning, a thin layer of SiO on the back is removed 2 Finally, each etching window with a size of 100 μm×100 μm is exposed, and the silicon wafer is placed in a KOH solution with a concentration of 40 vol% at 50° C., and both sides are wet-etched simultaneously until the silicon substrate is penetrated. The formed double-layer flow field structure has macropores of equal diameter on the upper side and tapered holes on the lower side. The upper surface area is 800 μm×800 μm, the lower surface area is 730 μm×730 μm, the thickness of the macroporous layer is 300 μm, and the duty cycle...

Embodiment 3

[0043] Select an N(100) silicon wafer with a thickness of 300 μm and a resistivity of less than 15Ω·cm, and adopt the same method as the manufacturing process steps (1)-(4), and form a 1.5mm×1.5mm silicon wafer on the front surface of the silicon wafer. The corrosion window is wet-etched, that is, at 50°C, in a KOH solution with a concentration of 40vol%, and the etching time is controlled to form a tapered hole with a depth of 200 μm; after cleaning, a thin layer of SiO on the back is removed 2 Finally, each etching window with a size of 100 μm×100 μm is exposed, and the silicon wafer is placed in a 50° C., 40% (Vol%) KOH solution to continue etching until the silicon substrate is penetrated. The formed double-layer flow field structure, the upper surface area of the large hole is 1.5mm×1.5mm, the lower surface area is 1.15mm×1.15mm, the total thickness of the large hole layer is 250μm, and the duty ratio is 85%; the small hole The layer has a cone-shaped pore structure, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com