Cutting head for machine tool

A technology of mechanical tools and cutting heads, which is applied in the field of light cutting heads, can solve the problems of no description, increase drill pipe, reduce vibration, etc., and achieve the effect of long cantilever length, increasing natural frequency and increasing natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention is further described by the following examples.

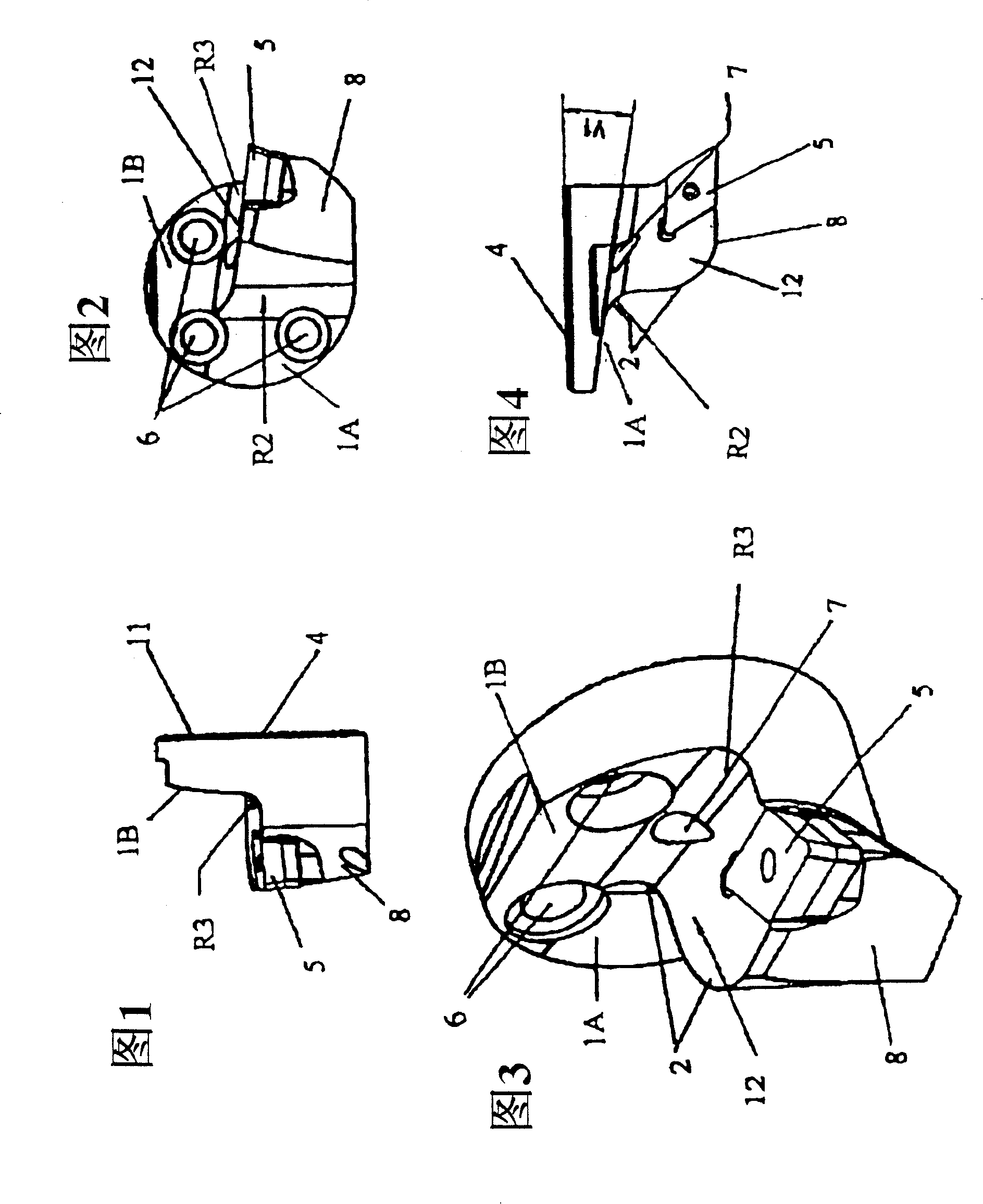

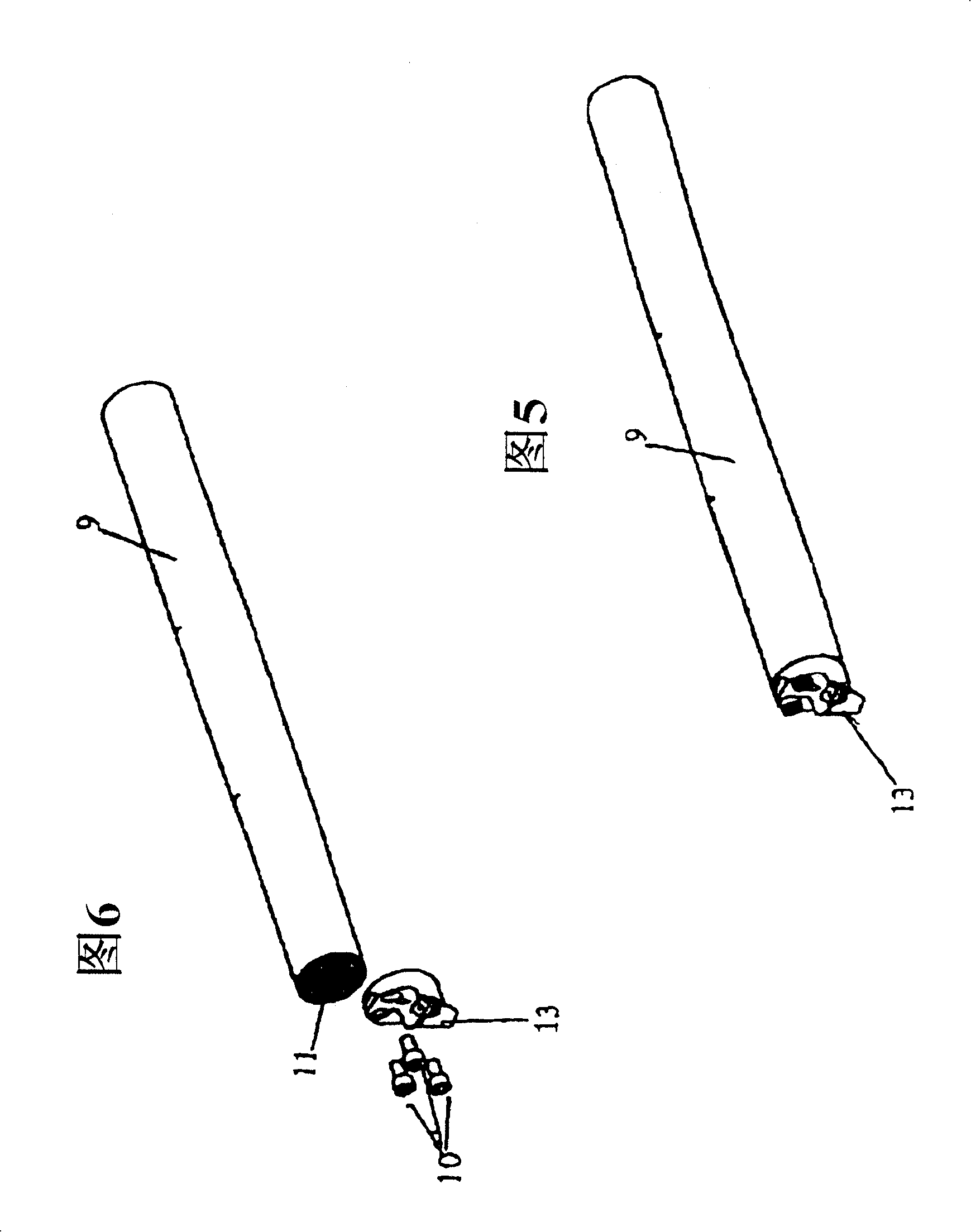

[0027] The side view of the cutting head shown in Figure 1 has a joint surface 4 on which there are serrations 11 and a protrusion 8 with an upper surface or slope 12, and the cutting head further comprises a cutting blade 5 and a cutting blade. The fixed surface of the blade. Also shown, with respect to the joint surface, is a free slope 1B that transitions on the protruding portion 8 towards the slope 12 into a concave surface R3. The protruding portion 8 comprises an element (not shown) for fixing the cutting insert 5 . Methods of securing cutting inserts are known in the art and so will not be further described here.

[0028] Figure 2 shows a front view of the adapter shown in Figure 1 showing holes for securing the cutting head to the adapter with threads and bolts. Also shown are the cutting inserts 5 on A1 , 1B and on the protruding portion 8 .

[0029] Figure 3 shows the transition from the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com