New type optical cable

A new type of optical cable technology, applied in the field of new optical cables, can solve problems affecting the information transmission performance of optical cables, uneven force, large internal stress of optical cables, etc., to ensure information transmission performance, reduce uneven force, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

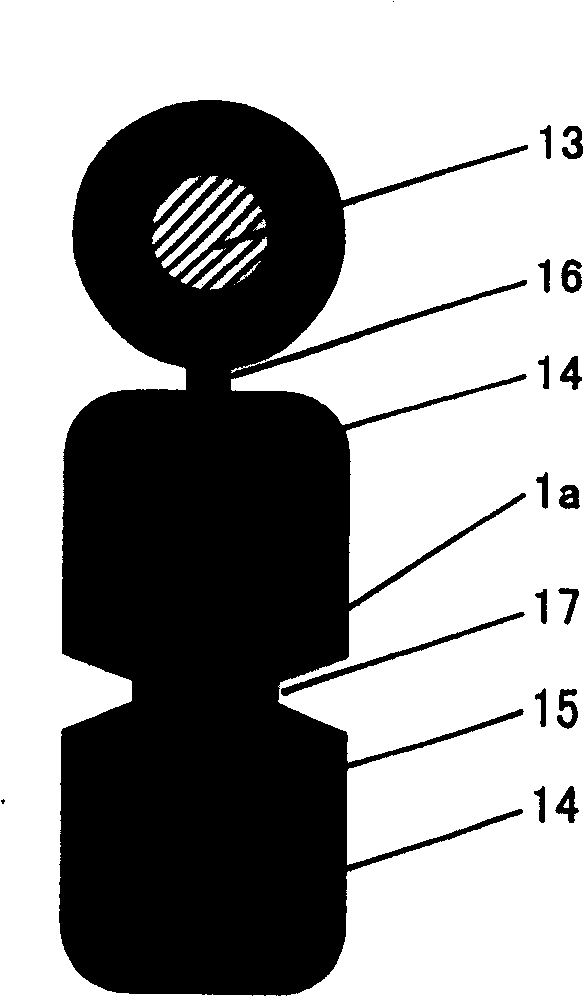

Embodiment 1

[0020] Embodiment one: figure 1 Shown optical cable, its manufacture step is (see Figure 5 ): the steel wire, the GFRP linear reinforcement and the single optical fiber that are released through the steel wire pay-off device 51, the GFRP pay-off device 53, and the fiber pay-off device 54 respectively pass through the extrusion mold of the assembly line device 55 and the extruder 56 (see Image 6 ), cooling water tank 57, traction pulley 58, and finally coiled by tension control wire receiving and arranging device 59 (wherein steel wire also passes through decontamination straightening device 52); meanwhile, steel wire, two GFRP reinforcements, and optical fiber first pass through the inner Four positioning holes 61, 62, 63, 64 on the mold 6, and then make the steel wire pass through the round hole 71 on the outer mold 7, two GFRP reinforcements and optical fibers through the waist-shaped hole 73 on the outer mold together, And make the optical fiber correspond to the "V"-sh...

Embodiment 2

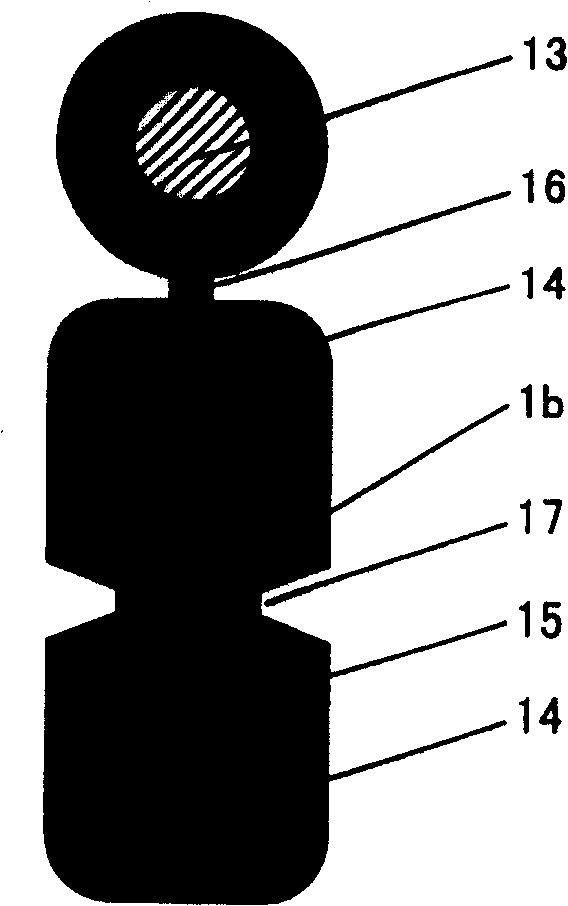

[0023] Embodiment 2: According to the manufacturing steps of Embodiment 1, the information transmission medium is changed from one optical fiber to two optical fibers 1b, and two pay-off racks are used for optical fiber pay-off, which can be obtained as follows figure 2 The cable shown has a maximum outer dimension of 4.0mm x 2.0mm. After performance testing, the attenuation constant of the optical cable is: 1310nm window 0.32 ~ 0.40dB / km, 1550nm window 0.18 ~ 0.25dB / km, and under the test conditions of 660 Newton tension and 1000 Newton / 100mm flattening force Attenuation change is less than 0.03dB / km.

Embodiment 3

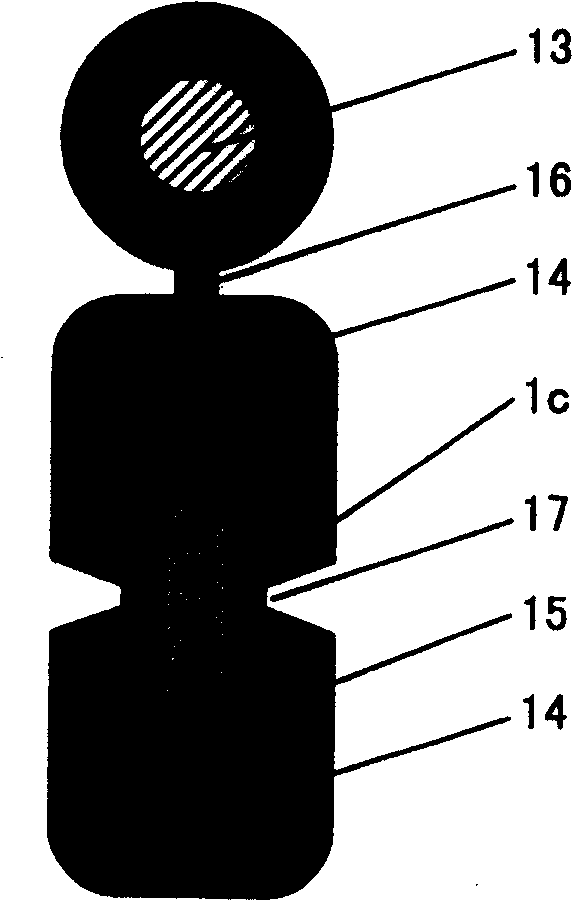

[0024] Embodiment three: according to the step of embodiment one, change the information transmission medium into a four-core optical fiber bundle 1c (this optical fiber bundle is a bundle-shaped object with a rectangular cross section), and the optical fiber bundle pay-off adopts a single optical fiber bundle pay-off stand, The pay-off tension of optical fiber bundle 1c is controlled at about 175 gram force, can make such as image 3 The cable shown has a maximum outer dimension of 6.0mm x 2.0mm. After performance testing, the attenuation constant of the optical cable is: 1310nm window 0.32 ~ 0.40dB / km, 1550nm window 0.18 ~ 0.25dB / km, and under the test conditions of 660 Newton tension and 1000 Newton / 100mm flattening force Attenuation change is less than 0.03dB / km.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com