Full solid band-gap optical fiber with low limited loss and low bending loss

A low-bending, all-solid technology, used in cladding optical fibers, light guides, optics, etc., can solve the problems of the influence of lossy fiber deformation, poor bending resistance, and high transmission loss, to optimize the splice loss and improve the mechanical reliability of the optical fiber. performance, reducing the effect of limiting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

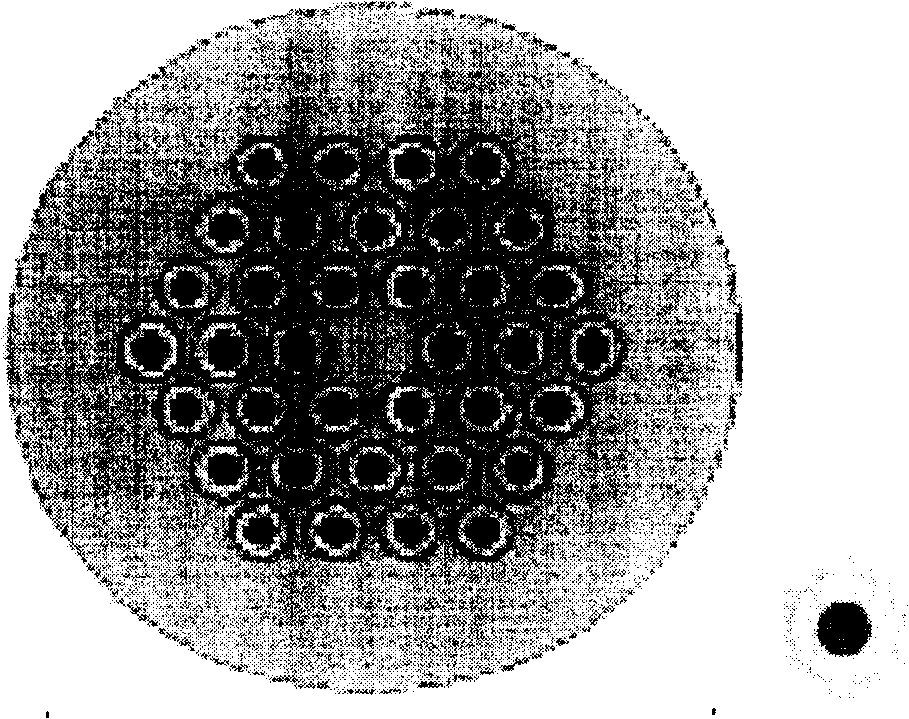

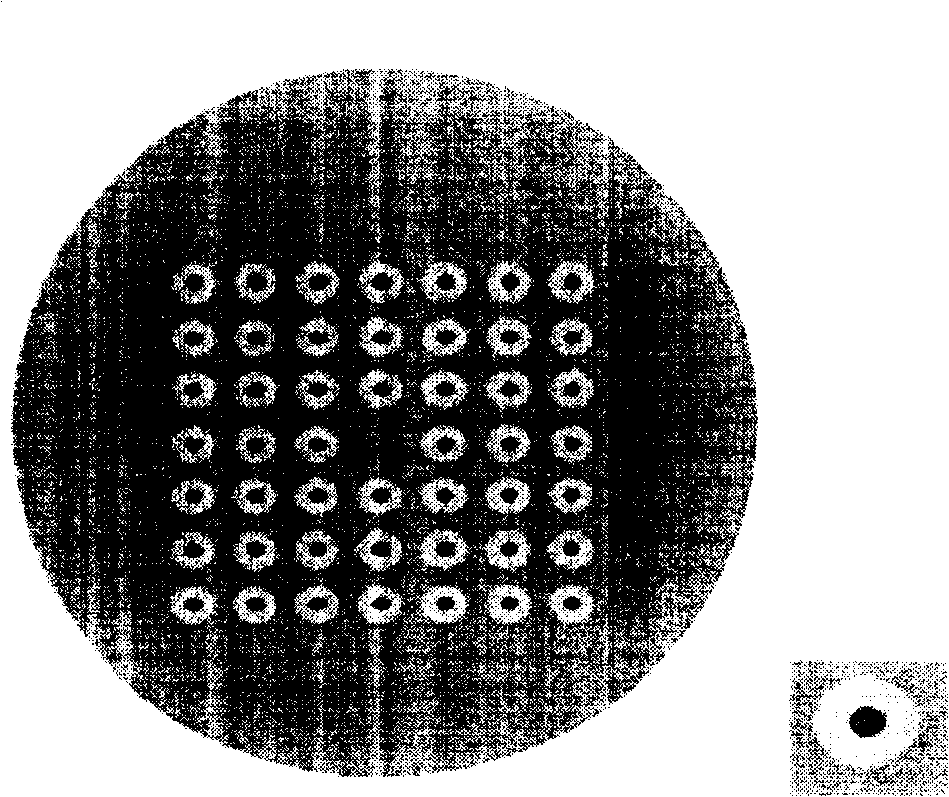

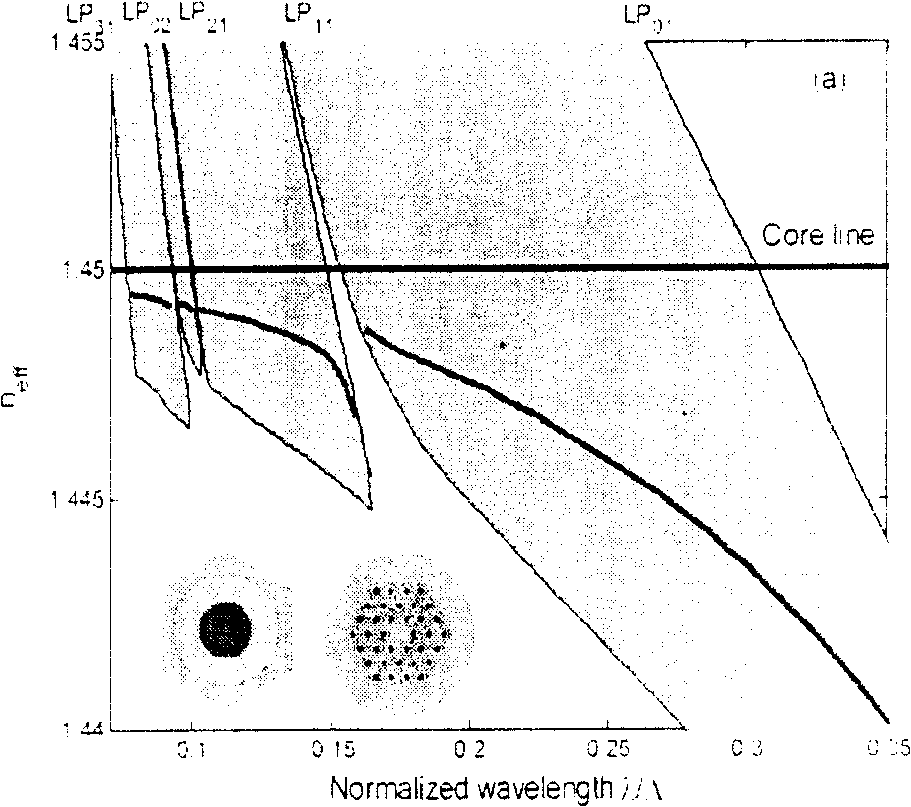

[0022] The working principle of the present invention and various embodiments of this type of optical fiber will be described in detail below with reference to the accompanying drawings. In order to study the light-guiding properties of all solid bandgap fibers, we have adopted the Full-vectorial Plane-wave method (PWM) and the Finite-difference Method (Finite-difference Method) using the ideal matching layer absorption boundary (PML) respectively. , FDM) [S.Guo et al.Opt.Express 12(2004)p.3341] Calculation of bandgap diagram and guided mode of all solid bandgap fiber.

[0023] As embodiment one, the present invention includes a core layer and a cladding layer, and the background material 1 of the optical fiber cladding layer has a certain refractive index n 1 , with a highly doped material with a refractive index n 3 The basic units 3 are distributed on the regular grid nodes of the cladding layer, and at least one layer of low refractive index n is wrapped around the highly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com