Use of polysaccharose sulfate for preparing medicine against grippal virus

A polysaccharide sulfate, anti-influenza virus technology, applied in the direction of antiviral agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

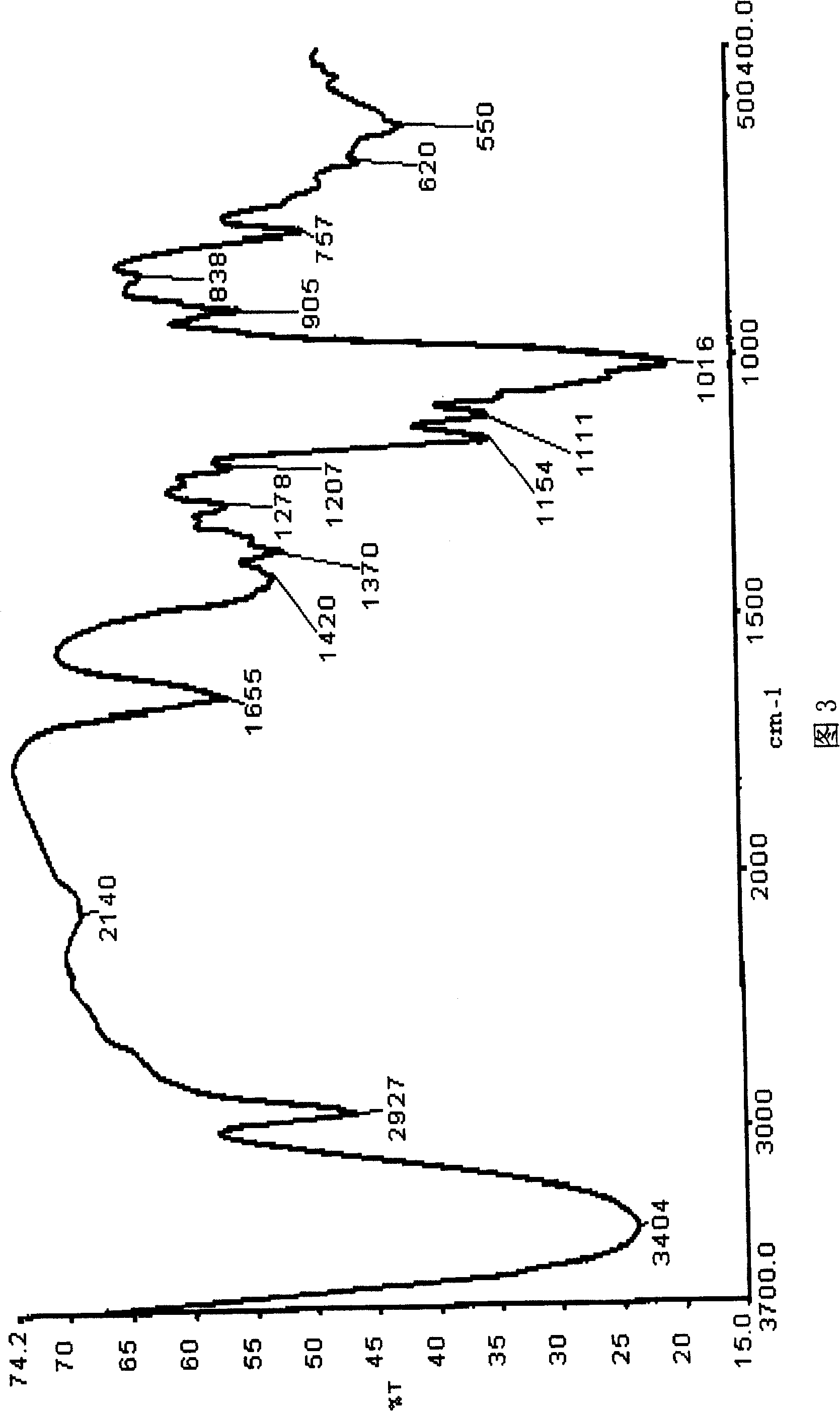

Image

Examples

Embodiment 1

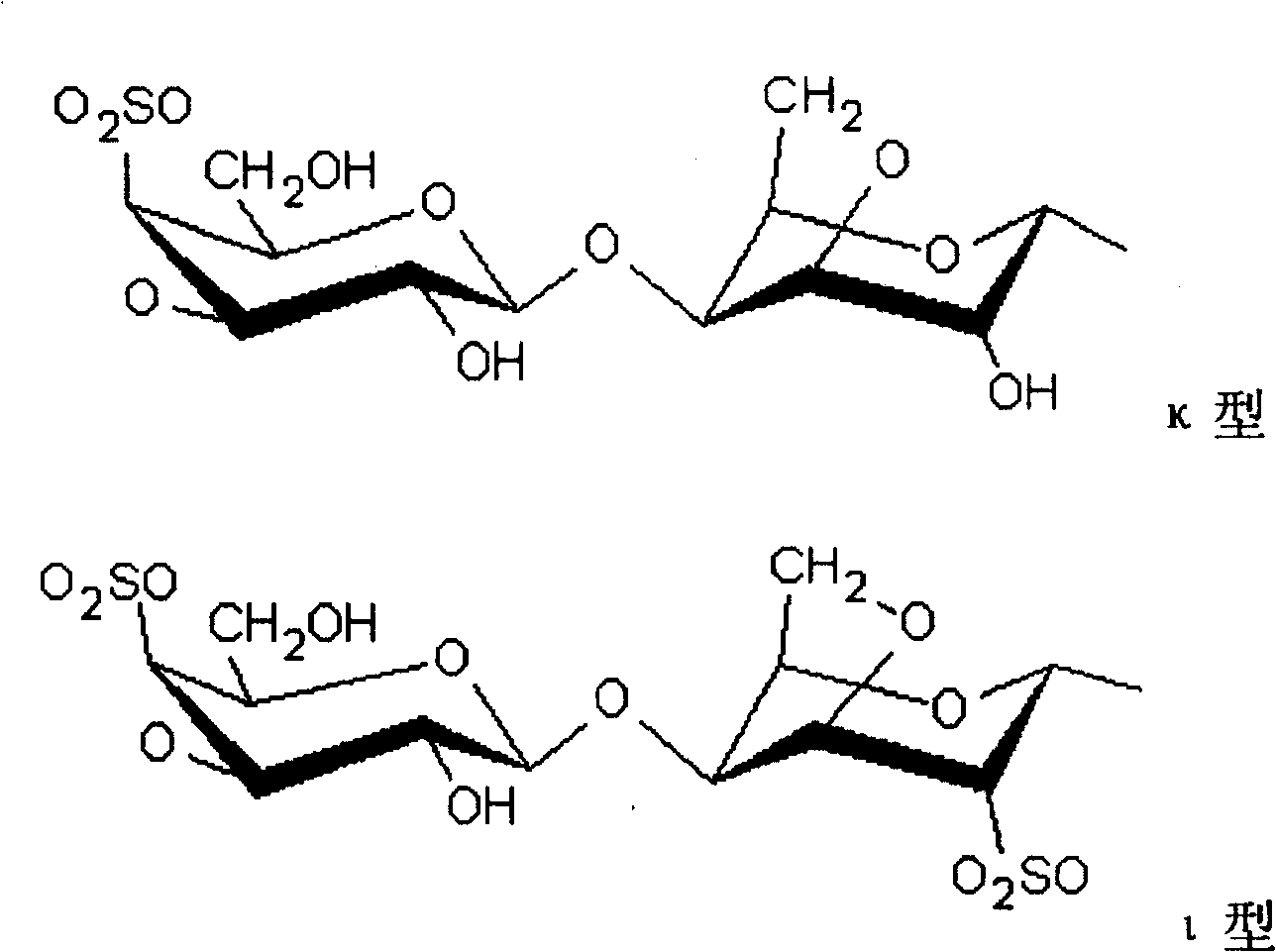

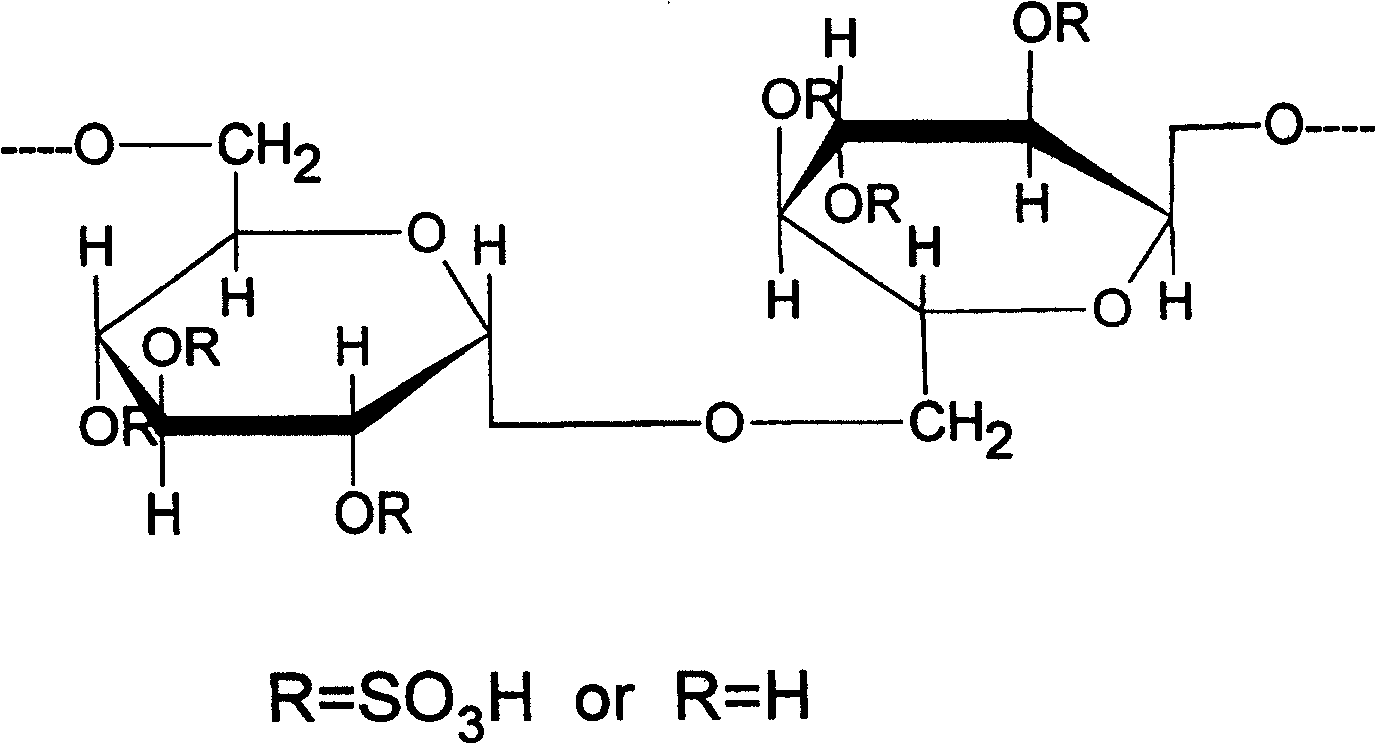

[0025] Embodiment 1: the preparation of Eucheuma polysaccharide (carrageenan)

[0026] Weigh a certain amount of dry Eucheuma auris (purchased from Xiamen Fisheries Research Institute), cut into pieces and wash, add 50 times the weight of hot water, stir and heat at 95°C for 3 hours. The crude polysaccharide extract was centrifuged at 5000 rpm for 10 minutes, and the supernatant was collected. Add KCl to make the final concentration 5%, stir evenly, let it stand overnight, and centrifuge at 500 rpm for 10 minutes to separate the insoluble matter. Dissolve the insoluble matter with distilled water, then add ethanol at a ratio of 3:1 (v / v), let it settle for 60 minutes, dry it under vacuum at 60°C, and grind it into a fine powder to obtain refined carrageenan powder. The molecular weight of the prepared carrageenan is higher than 500,000, and the substitution degree of sulfate group per monosaccharide is 0.45.

Embodiment 2

[0027] Embodiment 2: the preparation of laver polysaccharide

[0028] Weigh a certain amount of dry laver (produced in Pingtan, Fujian), cut it into pieces and wash it, add 50 times of distilled water to soak overnight, mash the laver with a masher, freeze it at -20°C, take it out and thaw it in microwave. After repeating 3 times, stir and extract in a 60°C water bath for 30 minutes, centrifuge at 3000rpm for 20 minutes, put the supernatant separately, add distilled water to the laver residue and repeat the extraction 2 times, combine the 3 supernatants, concentrate under reduced pressure at 50°C, and freeze-dry. get crude polysaccharides.

[0029] The laver crude polysaccharide was formulated into a 2% solution, and sulfuric acid was added to adjust the pH to 2.0. The polysaccharide solution flows through the regenerated 732 cation exchange resin column, which can effectively remove protein. The column solution was collected, concentrated to 3% w / v, and then the polysacchar...

Embodiment 3

[0030] Embodiment 3: the preparation of specific molecular weight carrageenan polysaccharide

[0031] The carrageenan (or commercial carrageenan) prepared in Example 1 was formulated into a 5% glue solution, placed in a constant temperature water bath, and fully mixed. Add sulfuric acid to adjust the pH to 2.5, and react at a constant temperature of 90°C for 120 minutes. After the reaction, neutralize with 1N NaOH solution immediately, and then filter with ultrafiltration membranes with different molecular weight cut-offs to prepare carrageenan polysaccharides with different molecular weights. The prepared carrageenan polysaccharide with specific molecular weight is spray-dried and used for the preparation of carrageenan polysaccharide sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com