Technology of manufacturing low expansion coefficient honeycomb ceramic kitchen range sheet

A technology with low coefficient of expansion and low coefficient of thermal expansion, used in ceramic products, household appliances, other household appliances, etc., can solve problems such as instability, and achieve the effects of stable water absorption, high softening temperature, and reduced thermal expansion coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

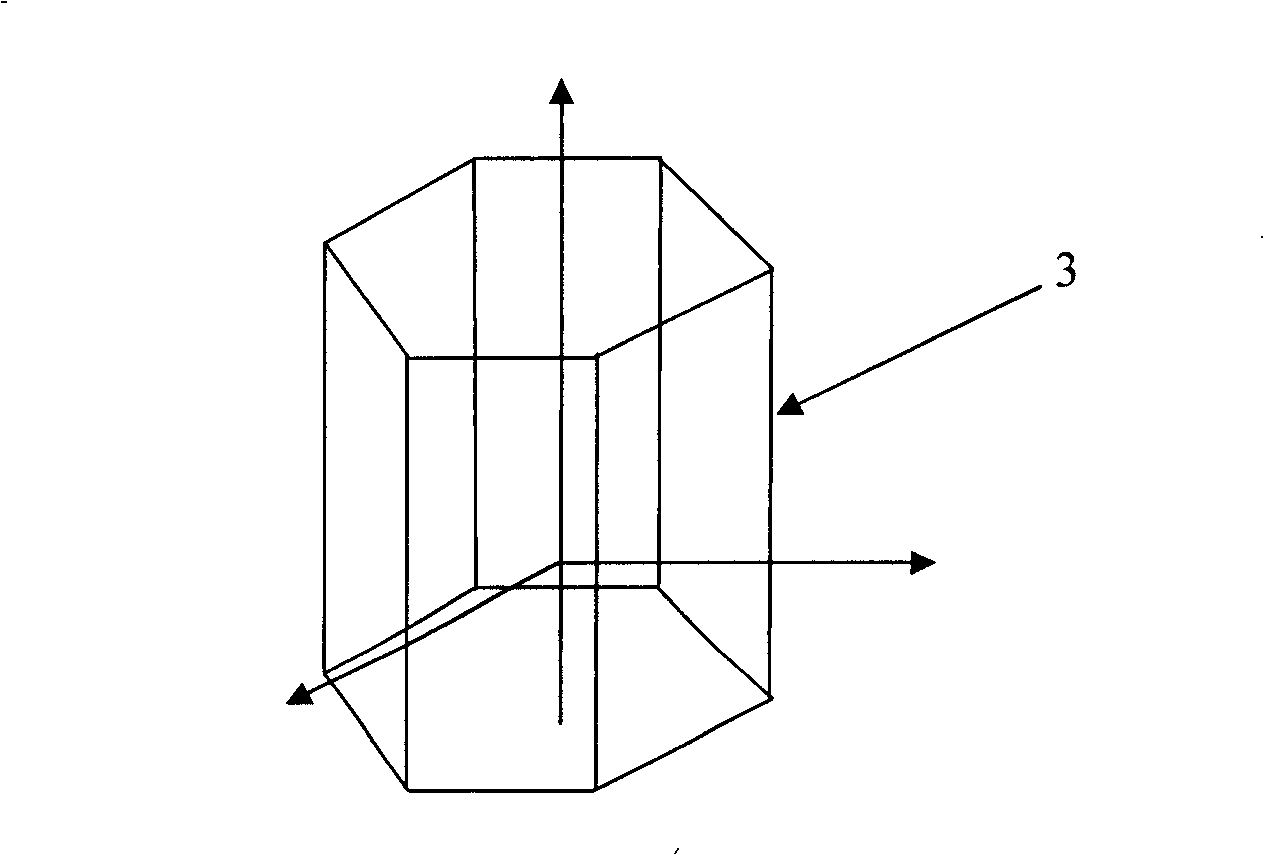

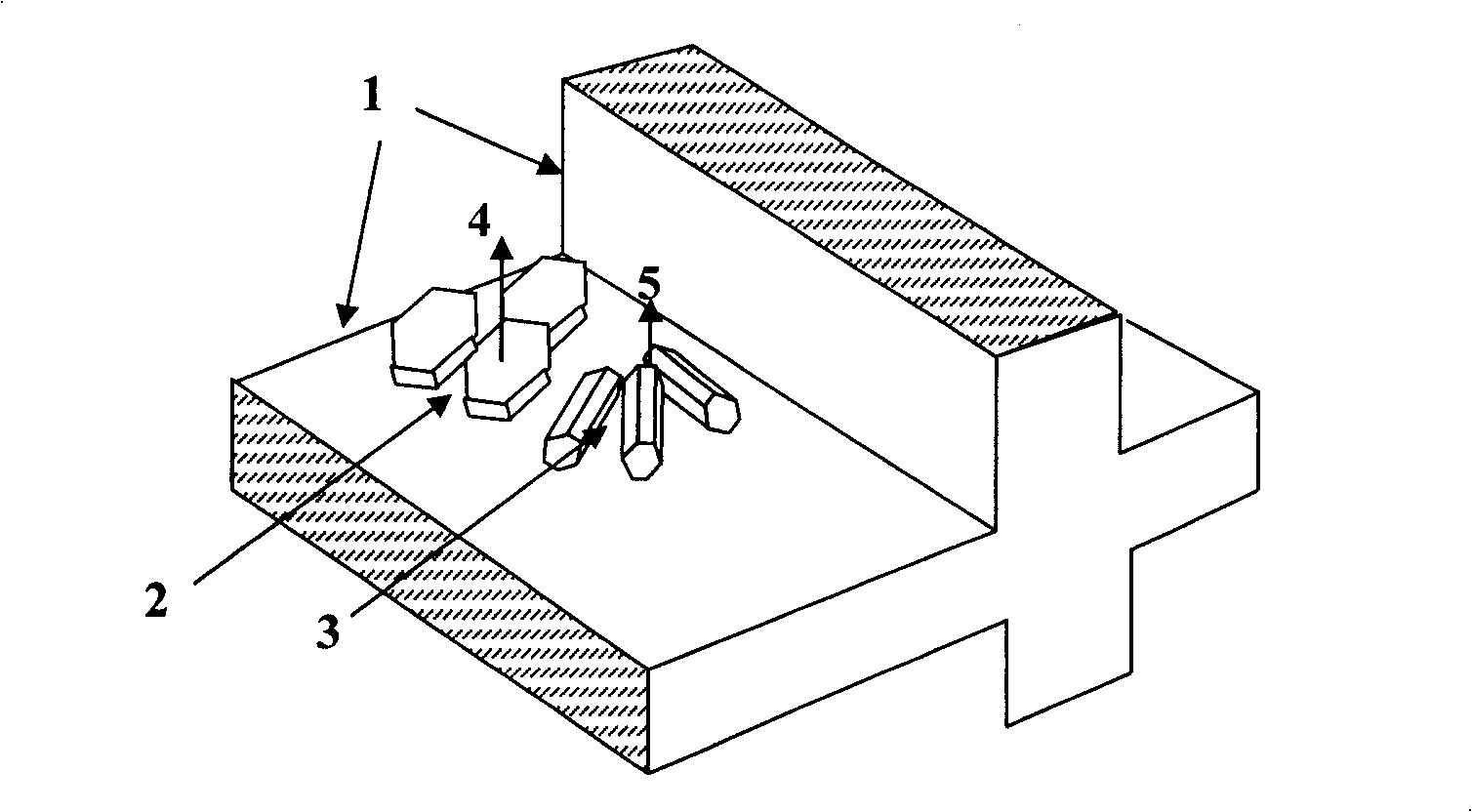

[0045] Manufacturing process of low expansion coefficient honeycomb ceramic cooktop:

[0046] A, material selection, select raw materials kaolin, talc, aluminum oxide and silicon dioxide, wherein the purity of kaolin and talc is more than 95%, and the purity of aluminum oxide and silicon dioxide is more than 99%. In order to make the cordierite synthesized in the product oriented, the selected raw materials must have flaky particles. Therefore, the scale-shaped kaolin is selected, generally weathered, sedimentary kaolin, and processed into powder after washing; the diameter-thickness ratio is selected. Large flaky talc, or fine enough granular talc (to ensure that the processed talc is in a flaky shape), so that the synthesized cordierite crystals can be oriented.

[0047] The morphology and particle size of the above-mentioned raw materials are:

[0048] raw material

appearance

flaky

D. 50 = 10μm

Kaolin

scaly

...

Embodiment 2

[0068] Manufacturing process of low expansion coefficient honeycomb ceramic cooktop:

[0069] A, material selection, select raw materials kaolin, talc, aluminum oxide and silicon dioxide, wherein the purity of kaolin and talc is more than 95%, and the purity of aluminum oxide and silicon dioxide is more than 99%. In order to make the cordierite synthesized in the product oriented, the selected raw materials must have flaky particles. Therefore, the scale-shaped kaolin is selected, generally weathered, sedimentary kaolin, and processed into powder after washing; the diameter-thickness ratio is selected. Large flaky talc, or fine enough granular talc (to ensure that the processed talc is in a flaky shape), so that the synthesized cordierite crystals can be oriented.

[0070] The morphology and particle size of the above-mentioned raw materials are:

[0071] raw material

appearance

flaky

D. 50 =20μm

Kaolin

scaly

D...

Embodiment 3

[0092] Manufacturing process of low expansion coefficient honeycomb ceramic cooktop:

[0093] A, material selection, select raw materials kaolin, talc, aluminum oxide and silicon dioxide, wherein the purity of kaolin and talc is more than 95%, and the purity of aluminum oxide and silicon dioxide is more than 99%. In order to make the cordierite synthesized in the product oriented, the selected raw materials must have flaky particles. Therefore, the scale-shaped kaolin is selected, generally weathered, sedimentary kaolin, and processed into powder after washing; the diameter-thickness ratio is selected. Large flaky talc, or fine enough granular talc (to ensure that the processed talc is in a flaky shape), so that the synthesized cordierite crystals can be oriented.

[0094] The morphology and particle size of the above-mentioned raw materials are:

[0095] raw material

appearance

flaky

D. 50 =30μm

Kaolin

scaly

D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com