Multifunctional diesel oil detergent

A multifunctional and detergent technology, which is applied in the field of multifunctional diesel detergent and diesel detergent composition composite agent, can solve problems such as poor water separation performance, diesel emulsification, unsatisfactory use effect, etc., to improve lubricating performance, remove Carbon accumulation, flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The concrete proportioning of each component of embodiment 1 is as follows:

[0031] Component %

[0032] 1) Polyisobutylene succinimide 10 (product of Nanjing Petrochemical Co., Ltd., T-151, molecular weight 1300)

[0033] 2) Boronated ashless dispersant 10 (Hitec 648)

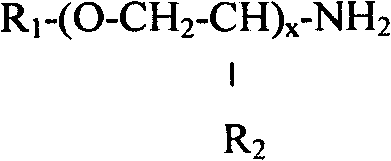

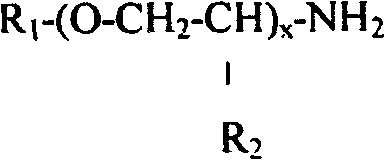

[0034] 3) Polyetheramine 10 (product of Nanjing Petrochemical Co., Ltd., molecular weight 1300)

[0035] 4) Cerium isooctanoate 1 (product of Nanjing Chenghe Chemical Factory)

[0036] 5) Diisooctyl nitrate 10 (Octel CI-0801)

[0037] 6) Glyceryl oleate and glyceryl linoleate 5 (product of Nanjing Petrochemical Co., Ltd.)

[0038] mixture (mixed by 2:3)

[0039] 7) Organic solvent 54 (distillation range 170-210°C)

Embodiment 2

[0062] Embodiment 2 The concrete proportioning of each component is as follows:

[0063] Component %

[0064] 1) Polyisobutylene succinimide 20 (product of Nanjing Petrochemical Co., Ltd., T-151, molecular weight 1000)

[0065] 2) Boronated ashless dispersant 5 (Hitec648)

[0066]3) Polyetheramine 5 (product of Nanjing Petrochemical Co., Ltd., molecular weight 1300)

[0067] 4) Cerium isooctanoate 1 (product of Nanjing Chenghe Chemical Factory)

[0068] 5) Diisooctyl nitrate 10 (Octel CI-0801)

[0069] 6) Glyceryl oleate 5 (product of Nanjing Petrochemical Co., Ltd.)

[0070] 7) Organic solvent 54 (distillation range 170-210°C)

Embodiment 3

[0071] Embodiment 3 The specific proportioning of each component is as follows:

[0072] Component %

[0073] 1) Polyisobutylene succinimide 5 (product of Nanjing Petrochemical Co., Ltd., T-151, molecular weight 1300)

[0074] 2) Boronated ashless dispersant 20 (Hitec648)

[0075] 3) Polyetheramine 5 (product of Nanjing Petrochemical Co., Ltd., molecular weight 1500)

[0076] 4) Cerium isooctanoate 1 (product of Nanjing Chenghe Chemical Factory)

[0077] 5) Diisooctyl nitrate 10 (Octel CI-0801)

[0078] 6) Glyceryl oleate 5 (product of Nanjing Petrochemical Co., Ltd.)

[0079] 7) Organic solvent 54 (distillation range 170-210°C)

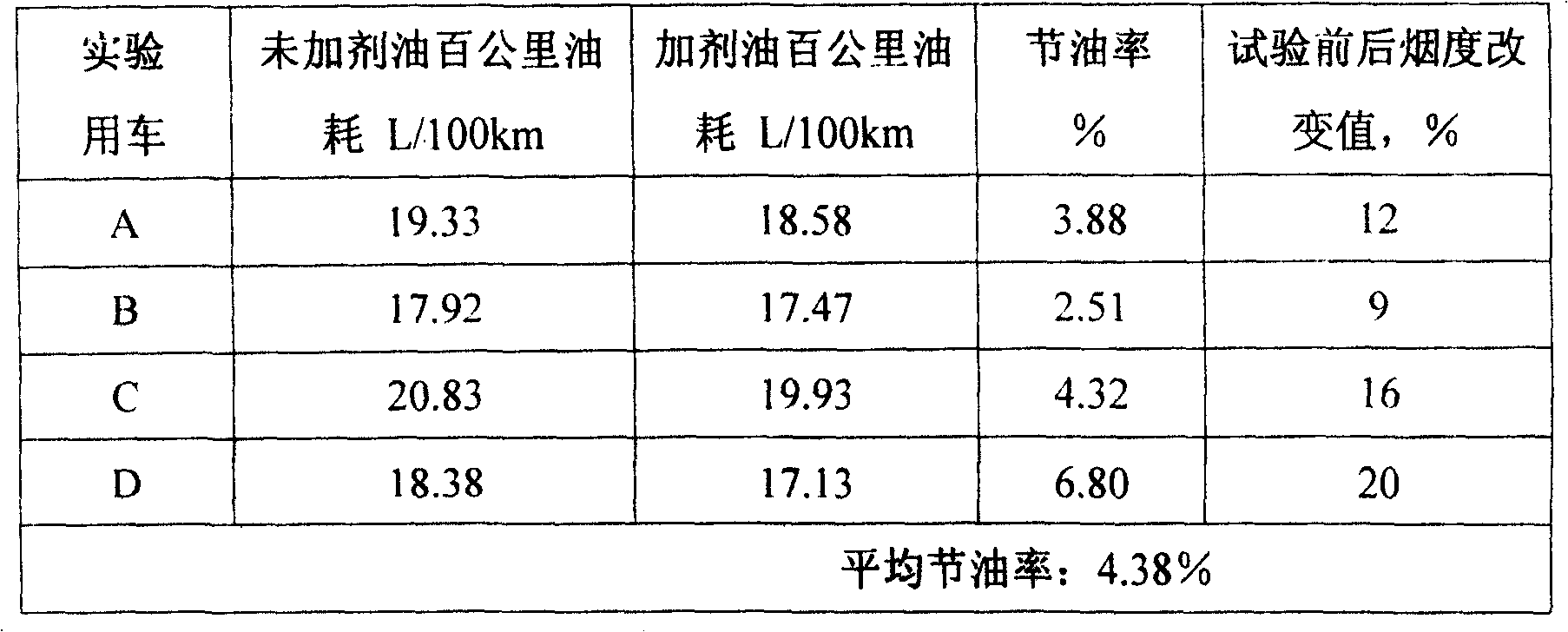

[0080] In order to evaluate the detergency of the present invention on engine nozzles, the applicant sent the present invention to Europe, and carried out a coking test according to the detergency evaluation method CEC-F-23-A-01 stipulated in the world fuel oil specification. This test uses the general standard test oil 818 # , PSA XU...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com