Battery pole piece and manufacturing method of lithium ion secordary battery containing the pole piece

A pole piece and frequency technology, which is applied in the field of lithium-ion secondary battery preparation, can solve problems such as unstable product quality, good or bad battery cycle performance, and uneven capacity distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the lithium-ion battery provided by the present invention comprises preparing the positive pole and the negative pole of the battery, and preparing the positive pole, the negative pole and the separator into a pole core, sealing the obtained pole core and electrolyte in the battery case, and the positive pole and the negative pole The preparation method comprises coating and / or filling the slurry containing the positive electrode active material, the conductive agent, the positive electrode binder and the solvent on the current collector, and the slurry containing the negative electrode active material, the negative electrode binder and the solvent Coating and / or filling on the current collector, drying, and rolling the dried current collector containing the positive electrode active material, conductive agent and positive electrode binder and the current collector containing the negative electrode active material and negative electrode binder ,...

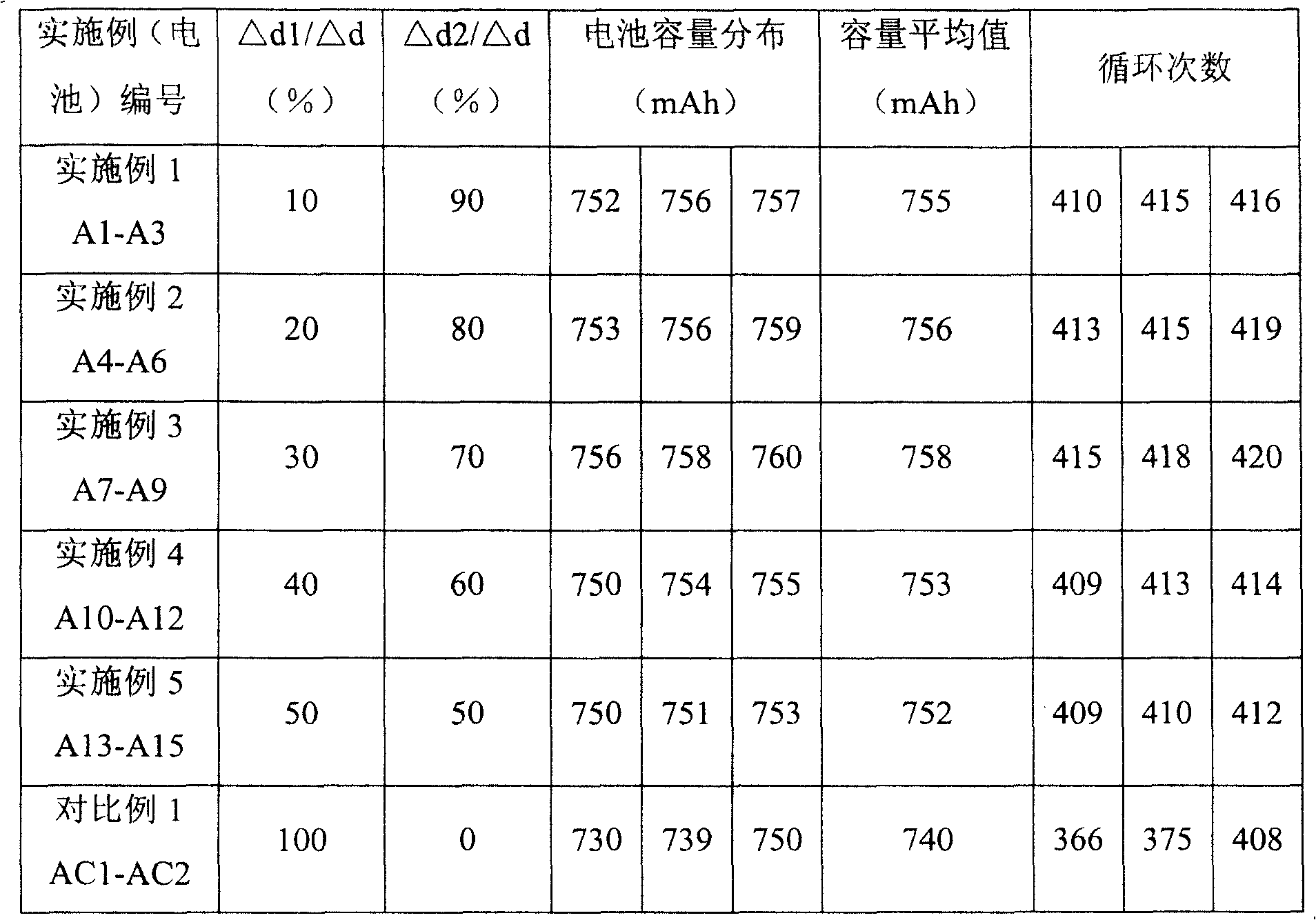

Embodiment 1

[0040] This example is used to illustrate the preparation method of the lithium ion secondary battery provided by the present invention.

[0041] (1) Preparation of positive electrode

[0042] 100 g of the positive active ingredient LiCoO 2 , 5 grams of binder polyvinylidene fluoride, 5 grams of conductive agent acetylene black were added to 50 grams of N-methylpyrrolidone, and then stirred in a mixer to form a uniform positive electrode slurry.

[0043] The slurry was evenly coated on both sides on an aluminum foil with a thickness of 20 microns, dried at 150° C., and cut to obtain a positive electrode sheet with a size of 355×41.5×0.205 mm. Rolling is then carried out, Δd1 / Δd=10% after the first rolling, and Δd2 / Δd=90% after the second rolling; a positive electrode sheet with a thickness of 0.145 mm is obtained. It contains 5.9 grams of active ingredient LiCoO 2 .

[0044] (2) Preparation of negative electrode

[0045] Add 100 grams of natural graphite, an active compon...

Embodiment 2-5

[0050] This example is used to illustrate the preparation method of the lithium ion secondary battery provided by the present invention.

[0051] The battery pole piece and the battery were prepared according to the method of Example 1, the difference was that during the rolling process of the positive and negative pole pieces, the change values Δd1 and Δd2 of the thickness of the pole pieces during the primary rolling and secondary rolling were changed respectively, The values of Δd1 / Δd after the first rolling are 20%, 30%, 40%, and 50%; the values of Δd2 / Δd after the second rolling are 80%, 70%, 60%, and 50%. Square aluminum-case lithium-ion secondary batteries 043048A4-A6, 043048A7-A9, 043048A10-A12, and 043048A13-A15 with a size of 48×30×4.5 mm were prepared respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com