Electrolyte and preparation method, battery using electrolyte

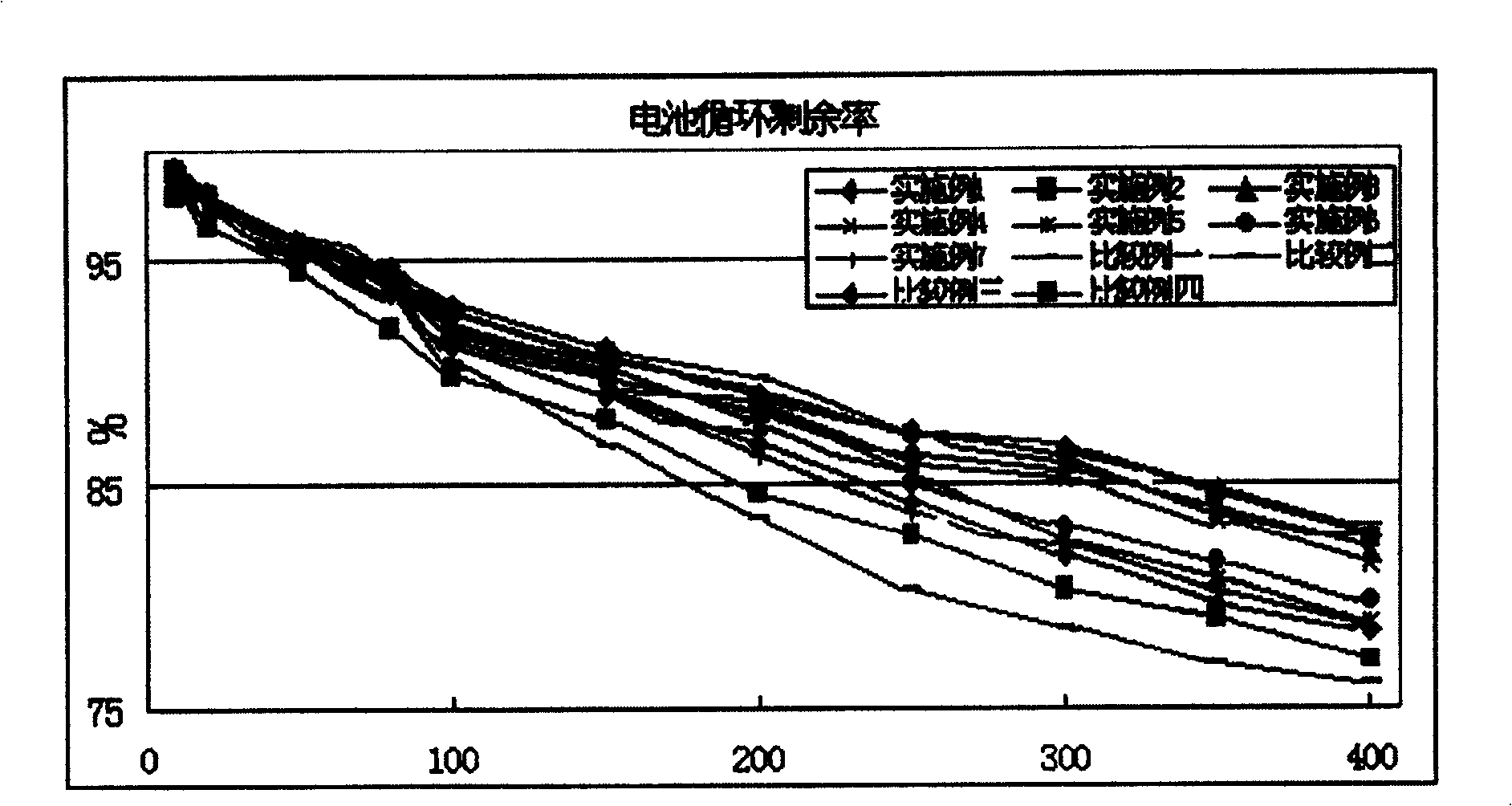

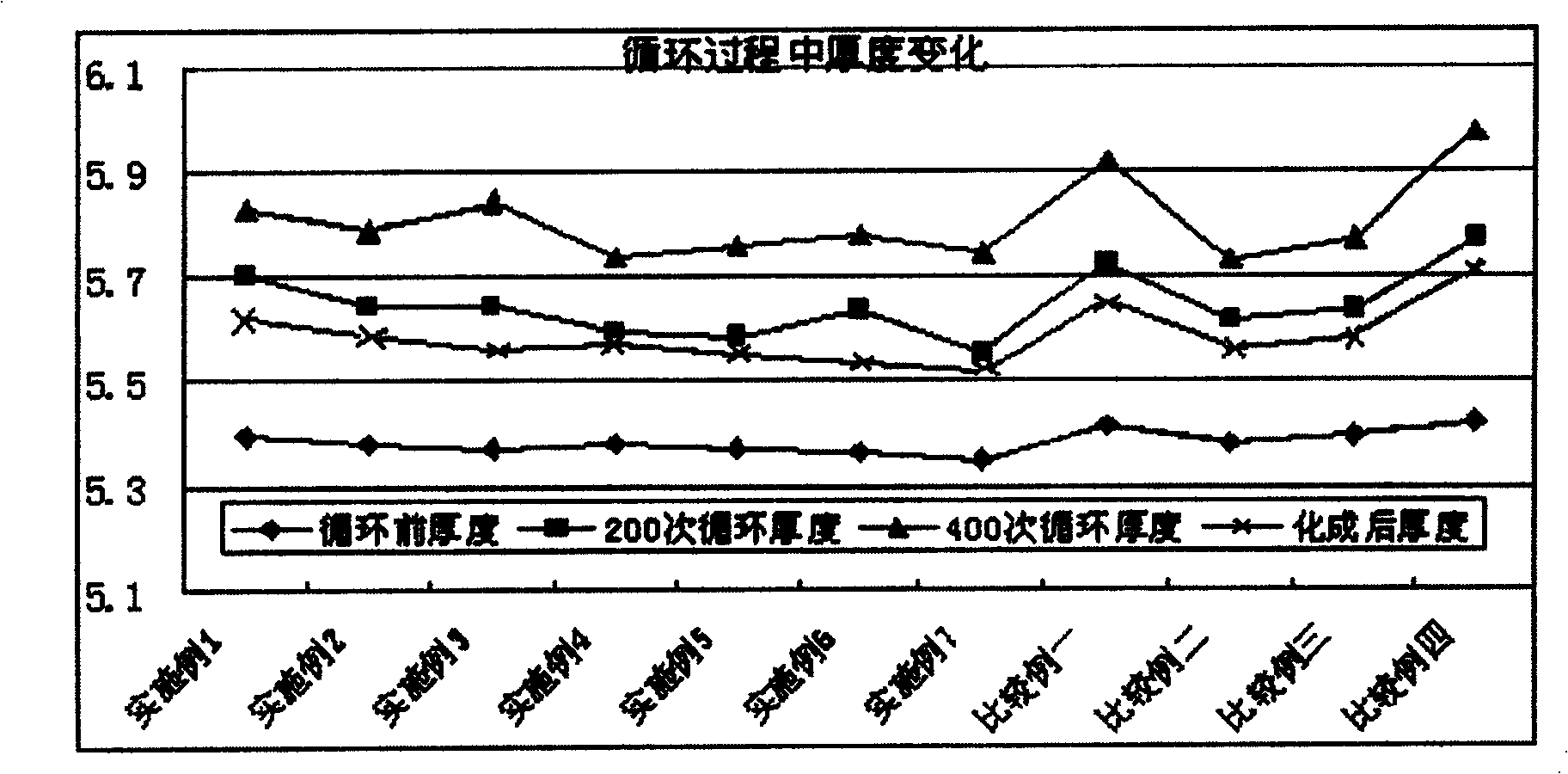

An electrolyte and material technology, applied in the field of lithium-ion secondary batteries, can solve problems such as cycle deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

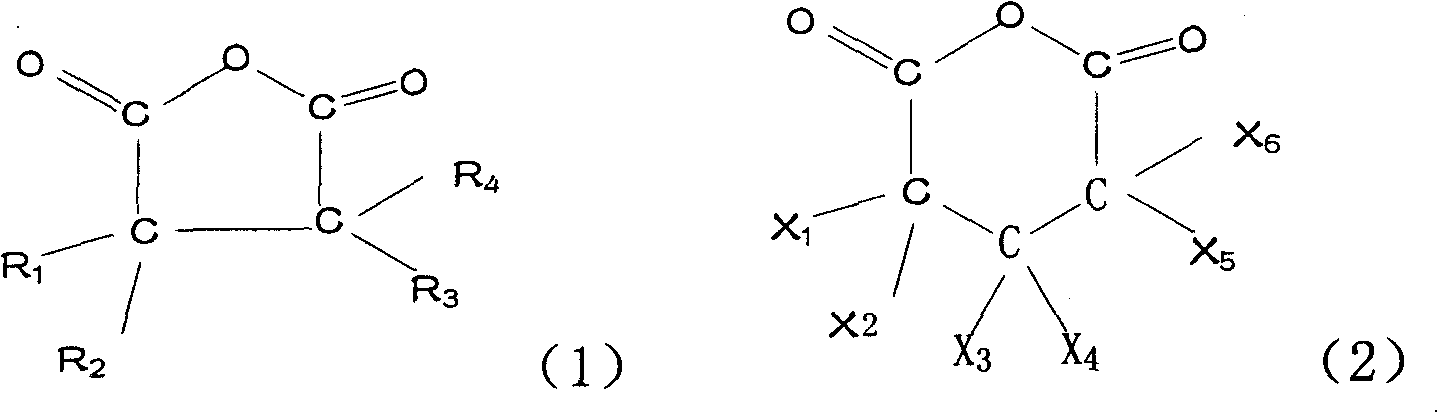

Method used

Image

Examples

preparation example Construction

[0085] The preparation method of the electrolytic solution of the present invention comprises the following steps: placing the organic solvent after mixing evenly, and containing succinic anhydride C 4 h 4 o 3 , propane sultone PS and vinyl sulfite ES mixed additives, shake well and leave for 0-24 hours, then add to the prepared organic solvent, seal and bake in vacuum at 20-90°C or directly for 1-24 hours After 24 hours, put it in the glove box and then add lithium salt, shake well and let it stand for more than 24 hours; or, after adding lithium salt in the organic solvent, first add succinic anhydride C 4 h 4 o 3 , seal and bake in a vacuum at 20-90°C or directly for 1-24 hours, then add propane sultone PS and vinyl sulfite ES in the glove box, shake well and leave for more than 24 hours; Add lithium salt to the solvent, place it for 1 to 24 hours, then add succinic anhydride C in any order 4 h 4 o 3 , propane sultone PS and vinyl sulfite ES, shake well and leave for...

Embodiment 1

[0094] Example 1 Electrolyte preparation: in the organic solvent of EC:EMC:DEC=1:1:1, add LiPF 6 Be prepared into a solution of 1.0mol / L, after standing for 1 hour, take the above-mentioned solution system as the main body to add its total amount of 0.3wt% solid powder succinic anhydride C 4 h 4 o 3 1. A total amount of 2wt% of propane sultone PS and a total amount of 2wt% of vinyl sulfite ES were shaken and placed for more than 24 hours. Preparation process of positive plate: 95wt% LiCoO 2 +3wt% PVDF+2wt% acetylene black, the three are mixed to form a paste, and then N-methylpyrrolidone is added to the mixture to make a paste and fully stirred to form a uniform slurry, which is coated on both sides of 18μm aluminum foil by a puller. The positive plate is obtained by vacuum heating and drying, and then cut into pieces to the required size. The preparation process of the negative electrode plate: 95wt% graphite + 2wt% dispersant + 3wt% binder, add an appropriate amount of w...

Embodiment 2

[0095] Embodiment 2 electrolyte preparation: in the organic solvent of EC:EMC:DEC=1:1:1, add LiPF 6 Be prepared into a solution of 1.0mol / L, after standing for 24 hours, take the above solution system as the main body, add its total amount of succinic anhydride C which is 1wt% therein 4 h 4 o 3 1. A total amount of 2wt% of propane sultone PS and a total amount of 2wt% of vinyl sulfite ES were shaken and placed for more than 24 hours. The ratio of positive and negative electrodes and the preparation and separator paper are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| sublimation point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com