Quick aging method for vacuum seal product

A technology of vacuum sealing and accelerated aging, which is used in fluid tightness testing, machine/structural component testing, instruments, etc. It can solve the problems of internal vacuum failure, difficult to obtain, expensive helium, etc. Achievable, easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

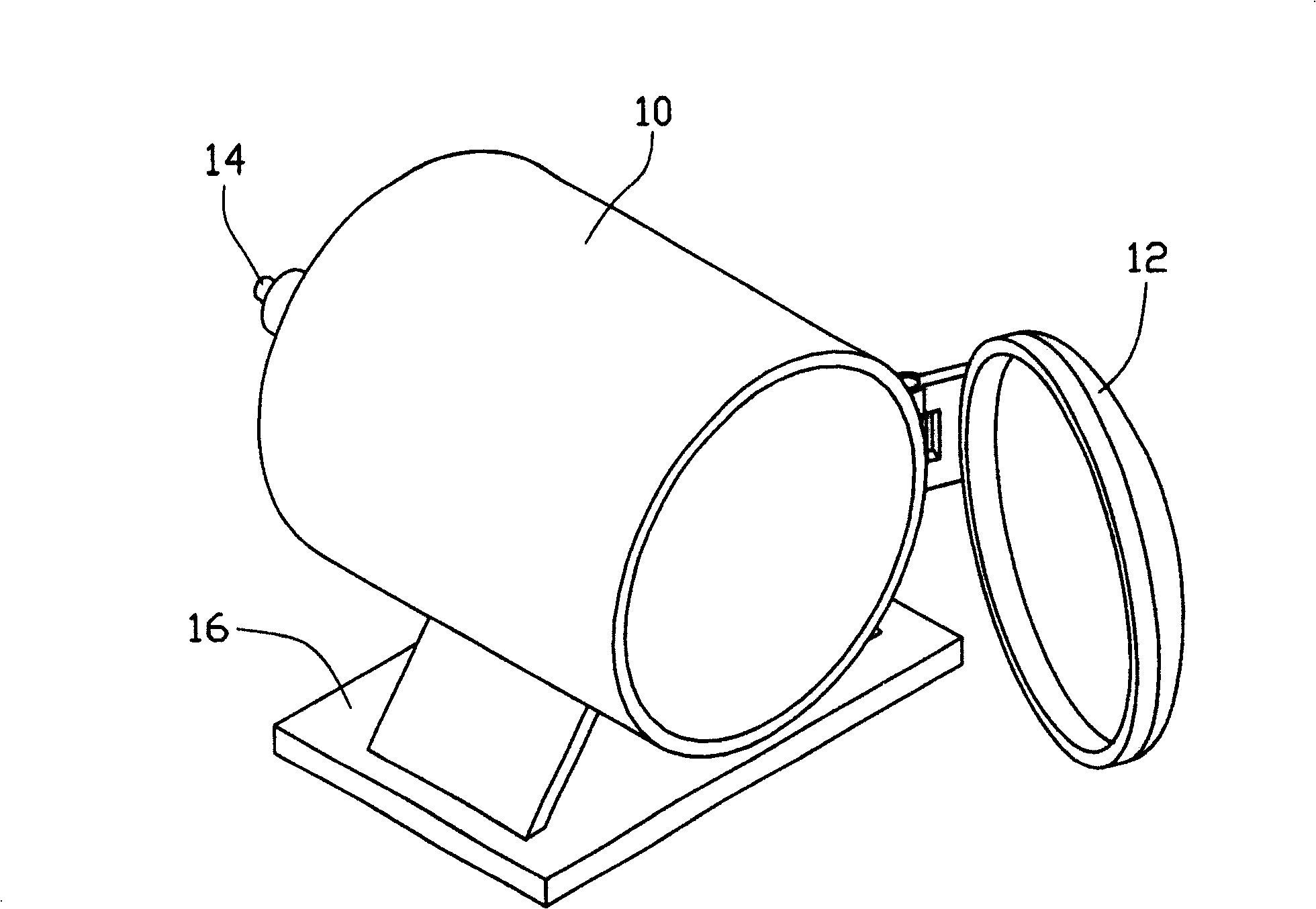

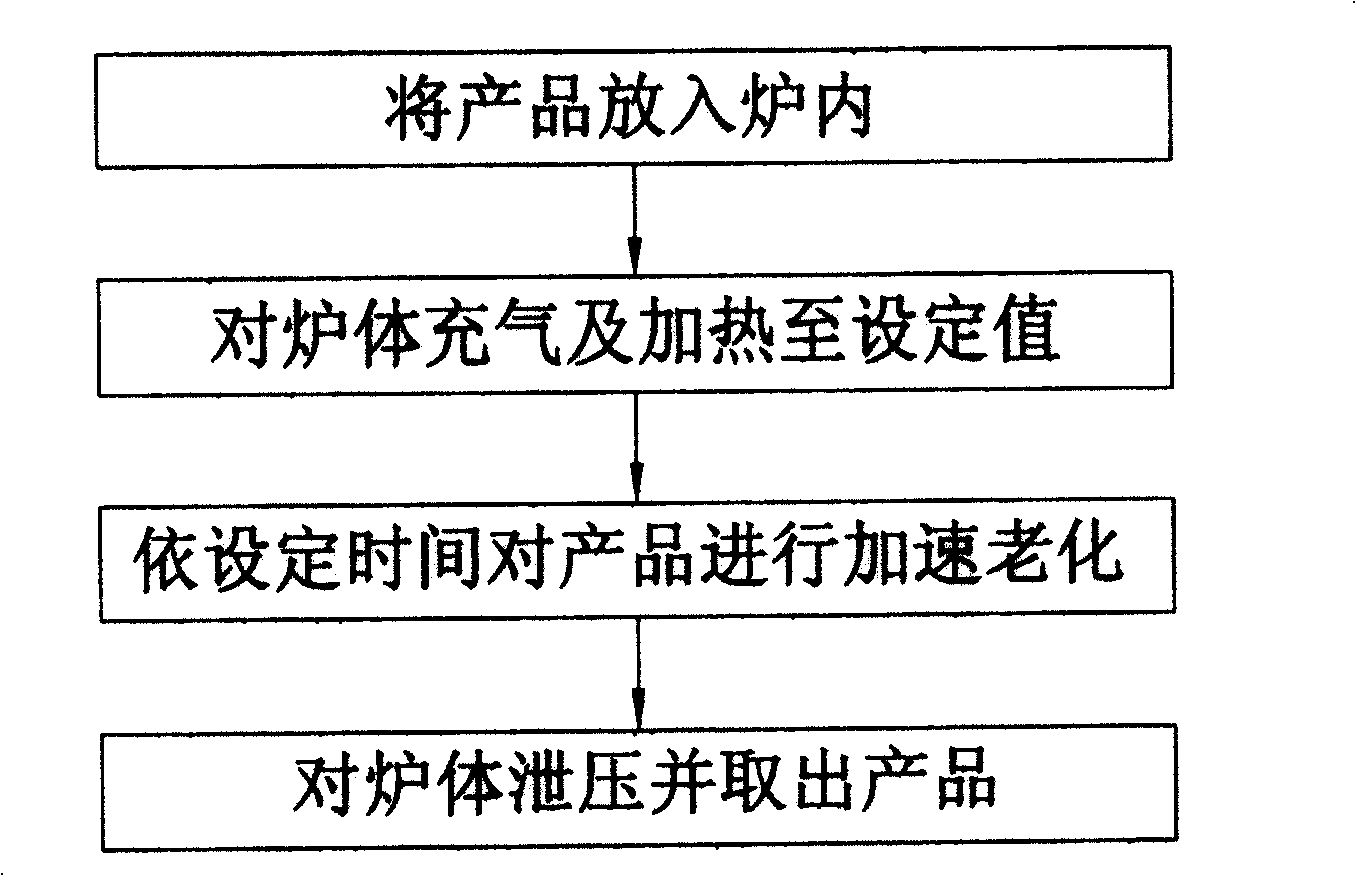

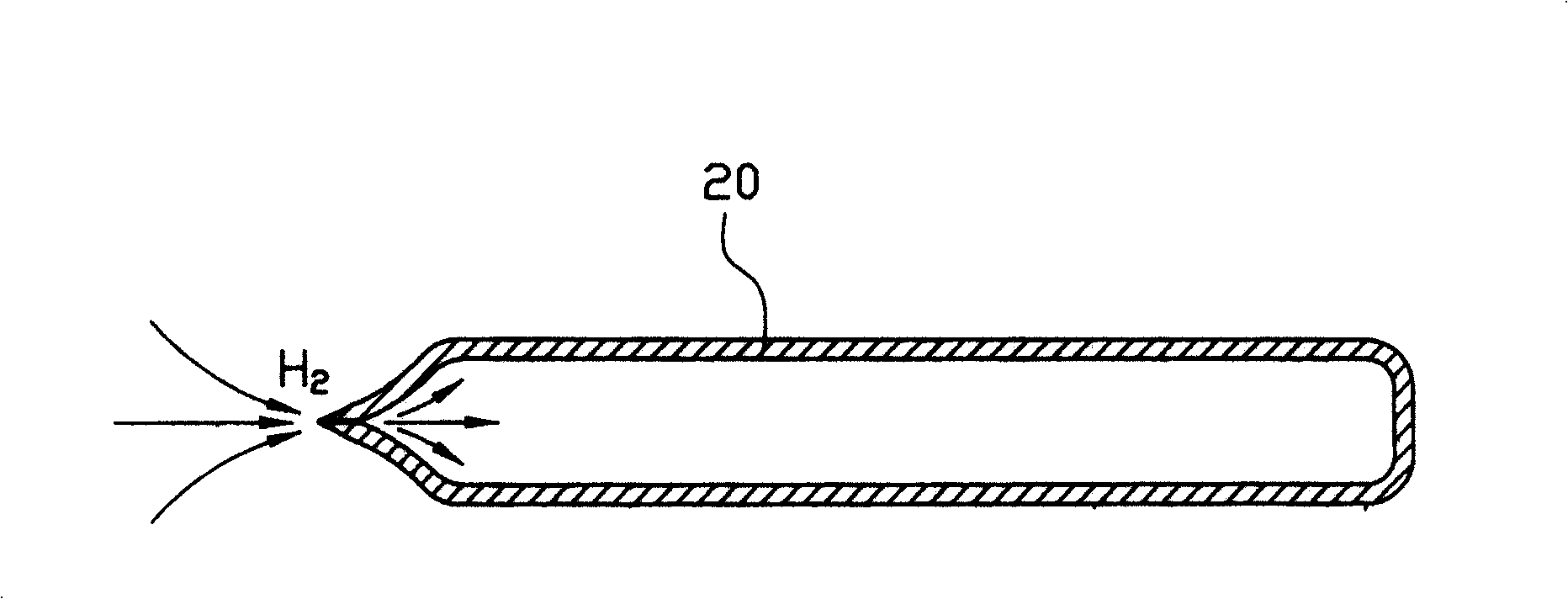

[0014] like Figure 1 to Figure 2 As shown, the basic principle of the accelerated aging process of the vacuum-sealed product of the present invention is to put the vacuum-sealed product into a furnace body 10, and perform an accelerated aging test in a heated and pressurized environment, so that defective products can be revealed in advance and eliminated. Here, the accelerated aging process takes a heat pipe as an example to carry out the aging test and to illustrate it. It mainly includes four steps, which are described separately below.

[0015] First, open the furnace door 12 of the body of furnace 10, put the vacuum-sealed product to be tested, i.e., the heat pipe, into the body of furnace 10, and the body of furnace 10 is provided with a heating device such as an electric heater (not shown) to control the body of furnace 10. Heating; In addition, the furnace body 10 is also provided with a pressurizing device (not shown) that stores nitrogen (N2) and hydrogen (H2) mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com