Repair method of high-voltage transmission line and failure testing device thereof

A high-voltage transmission line and fault detection technology, applied to fault locations, measuring devices, radio wave measuring systems, etc., can solve problems such as danger, large losses, and long response and repair time, so as to ensure reliable operation, reduce work burden, Easy to check the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

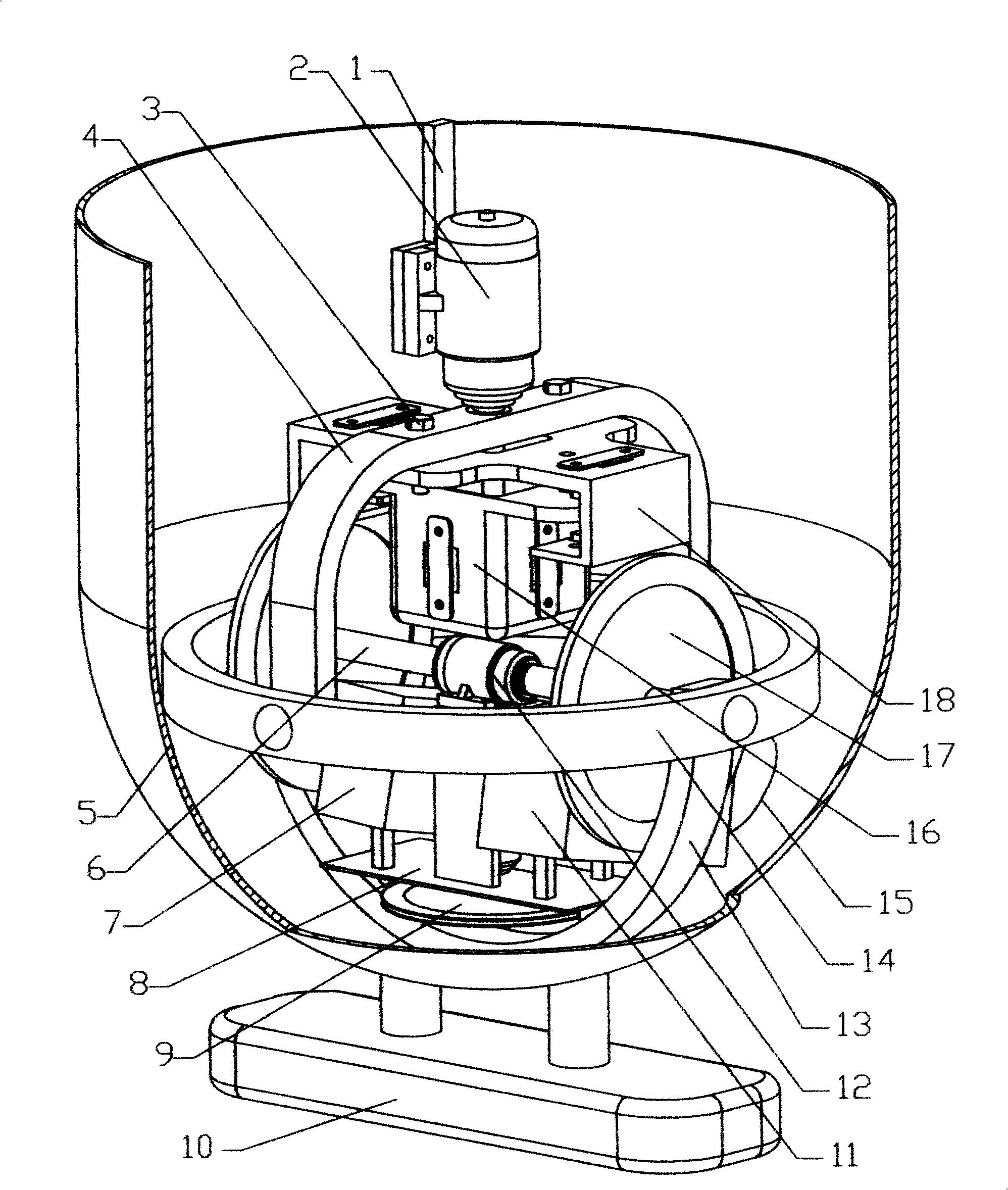

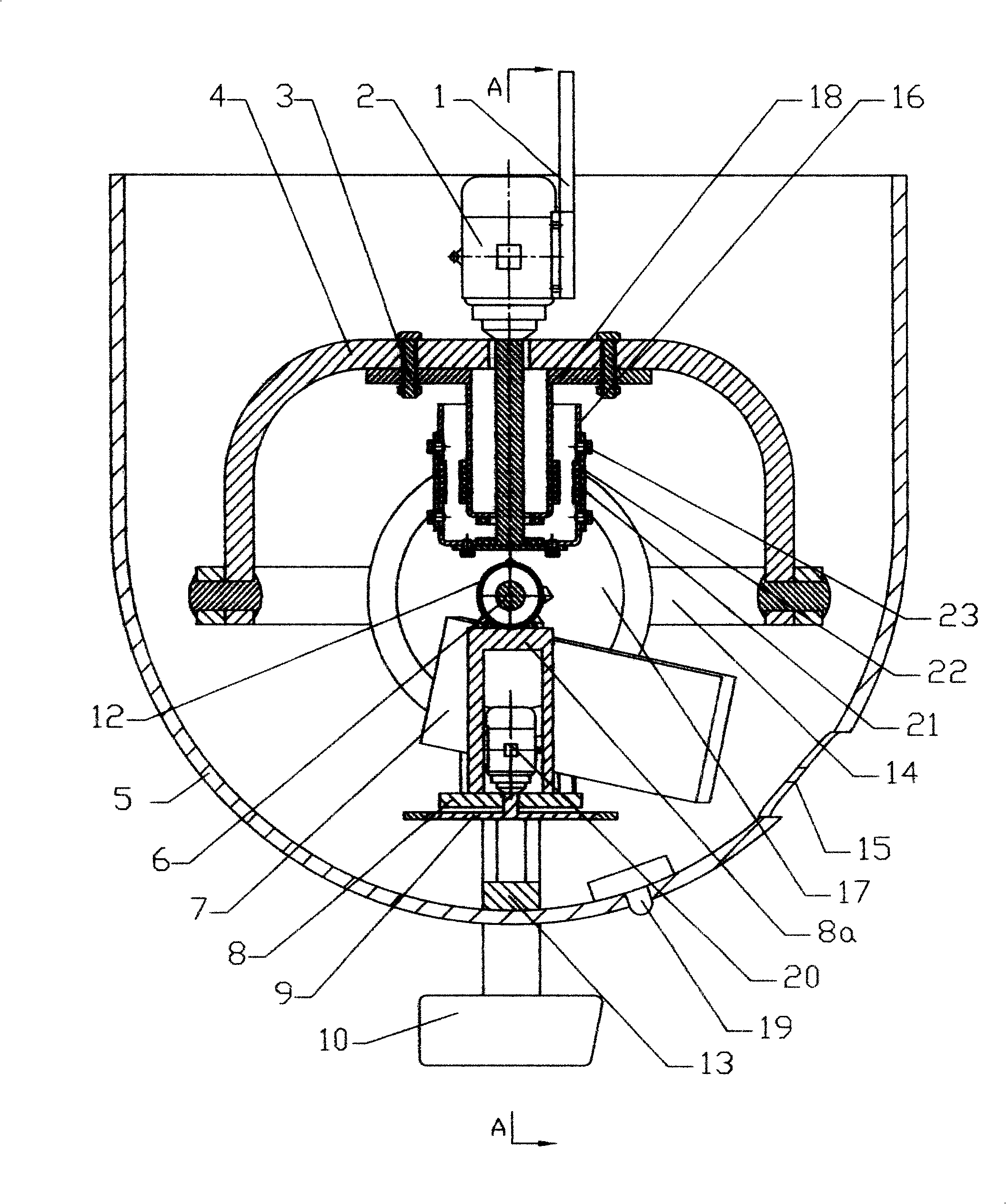

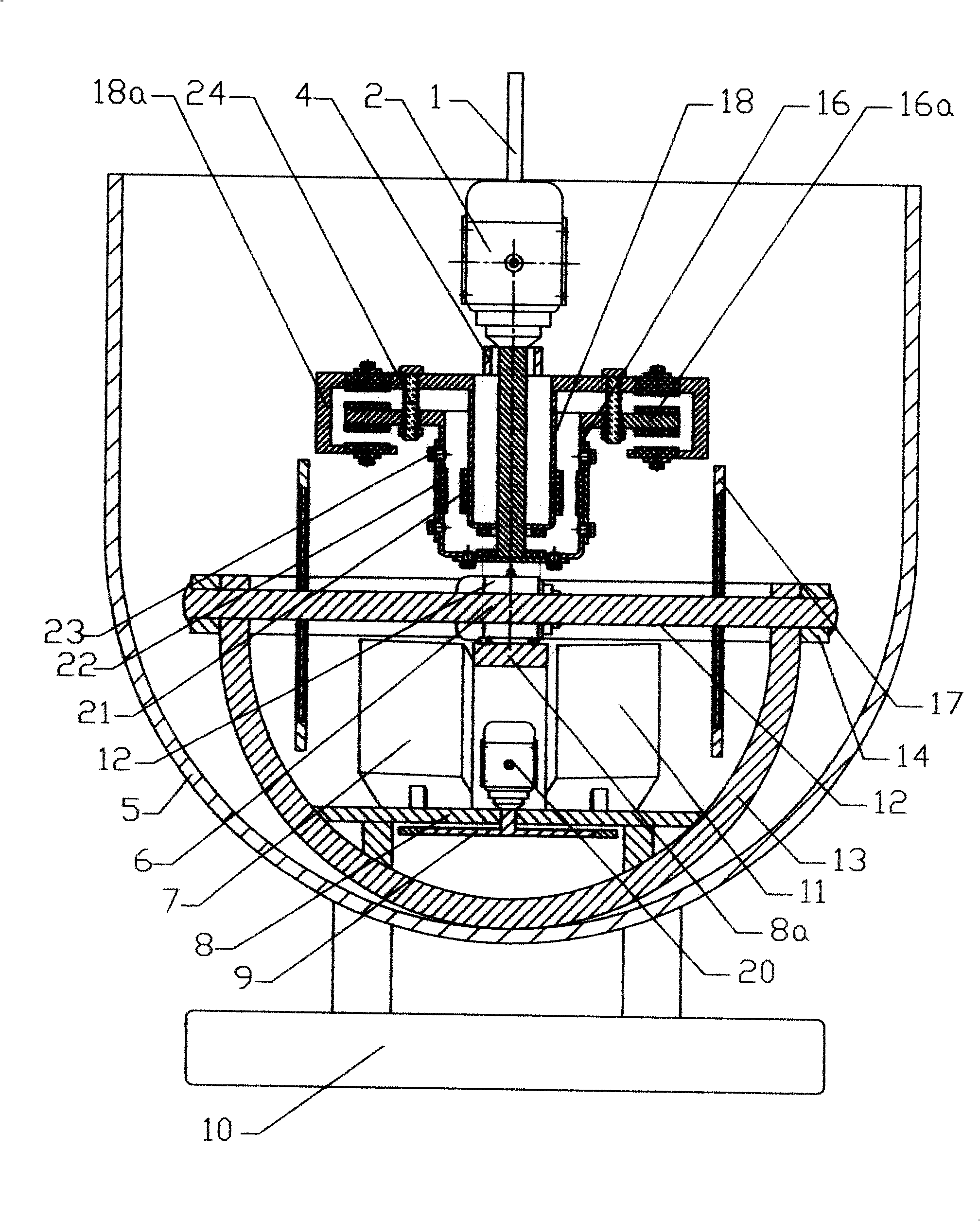

[0017] Embodiment 1 The high-voltage line automatic fault detection device of this embodiment can be structured from figure 1 , figure 2 with image 3 It can be seen that the device is a pod 5 fixed on the bottom of the helicopter and carrying a detection platform capable of automatic image data collection. The pod 5 is a cylinder with a spherical bottom. There is a detection platform 8 fixed to the bottom of the pod 5. The pod 5 is connected to the stepper motor 2 with brake on the helicopter through the magnet shock absorber and the attitude controller. Connect and install horizontal and vertical gyro stabilizers in the pod 5 to maintain the stability of the detection platform 8 in the pod 5 during flight.

[0018] The detection platform 8 includes an optical camera 7 and an infrared fault scanner 11 with a camera. A camera port 15 is opened on the pod 5 to facilitate image data collection; an electronic sensor 19 with a Hall element is installed under the camera port 15 to de...

Embodiment 2

[0031] Embodiment 2 The high-voltage line fault detection device of this embodiment can be structured from Figure 4 It can be seen that it is different from Embodiment 1 in that the magnet connecting the pod 5 and the aircraft's magnet shock absorber on the bottom surface of the outer shell 16 can also be a DC electromagnet 25, and a pressure sensor is installed on the inner core 18 to make the direct current The magnetic flux of the magnet 25 can be adjusted by receiving the signal of the pressure sensor by the microcomputer to realize online real-time adjustment, which can reduce the vibration as much as possible, which helps the optical camera 7 and the infrared fault scanner 11 to collect images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com