Method for making white-light organic light-emitting-diode

A light-emitting diode, organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of affecting the color of light emission, white light color impurity, etc., and achieve the effect of high brightness and luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

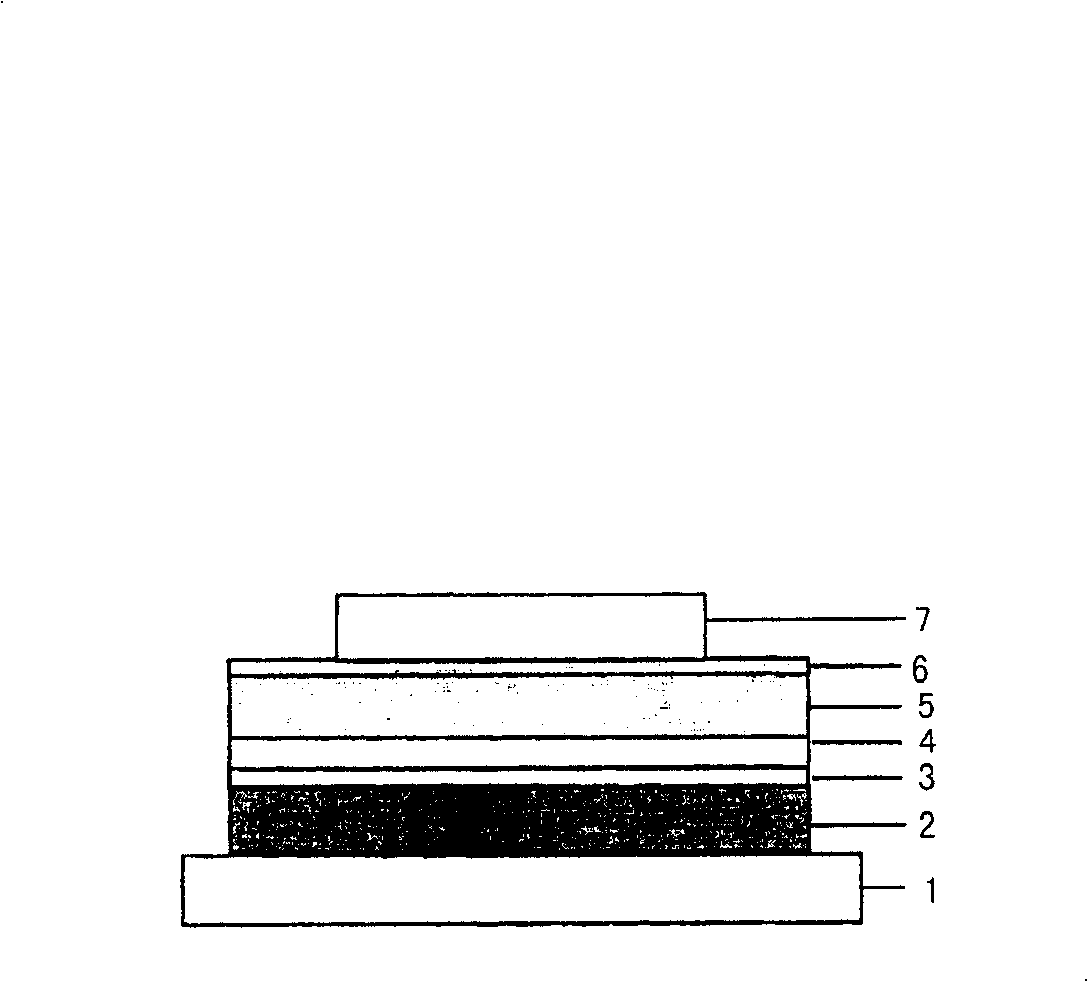

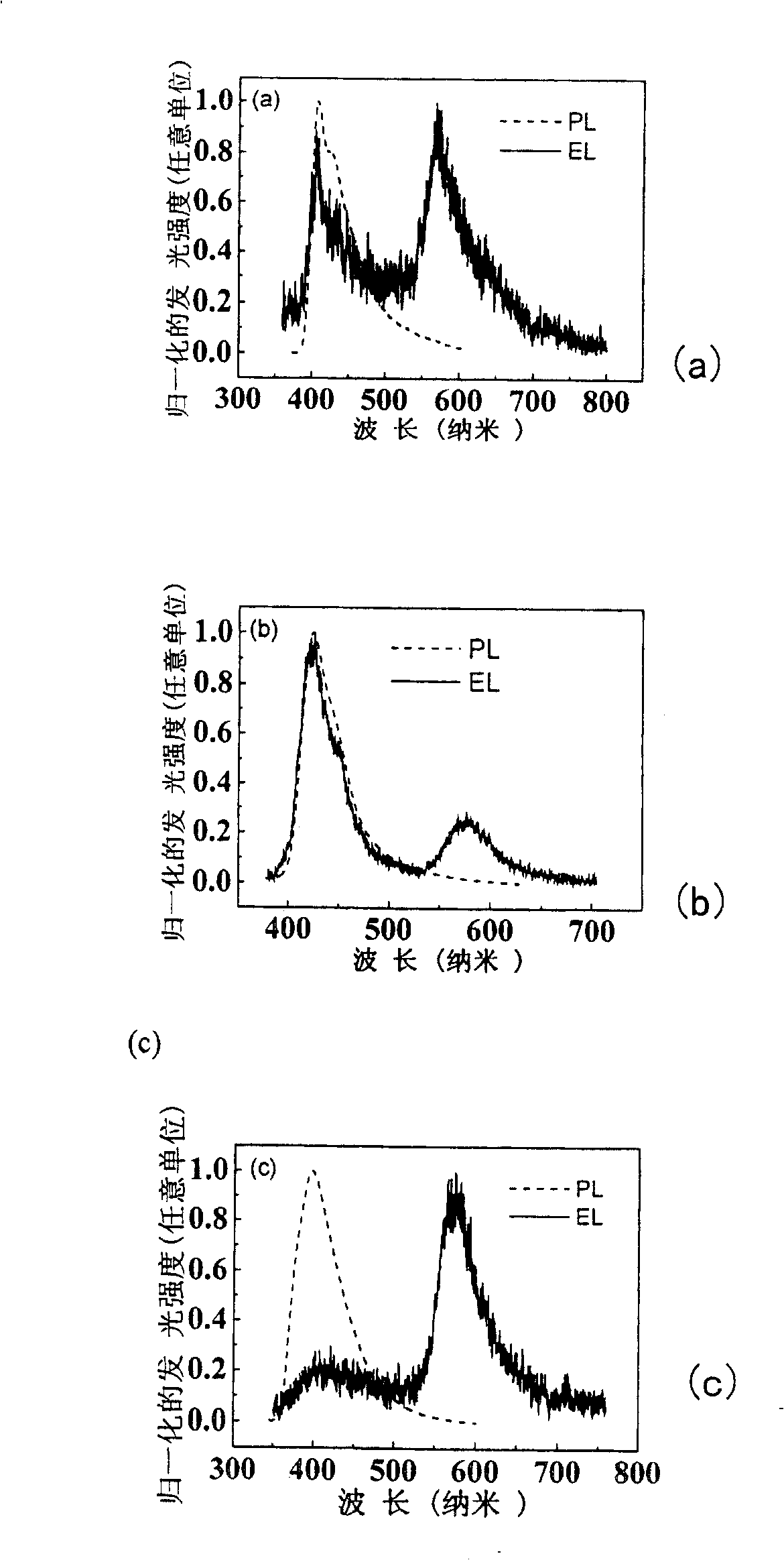

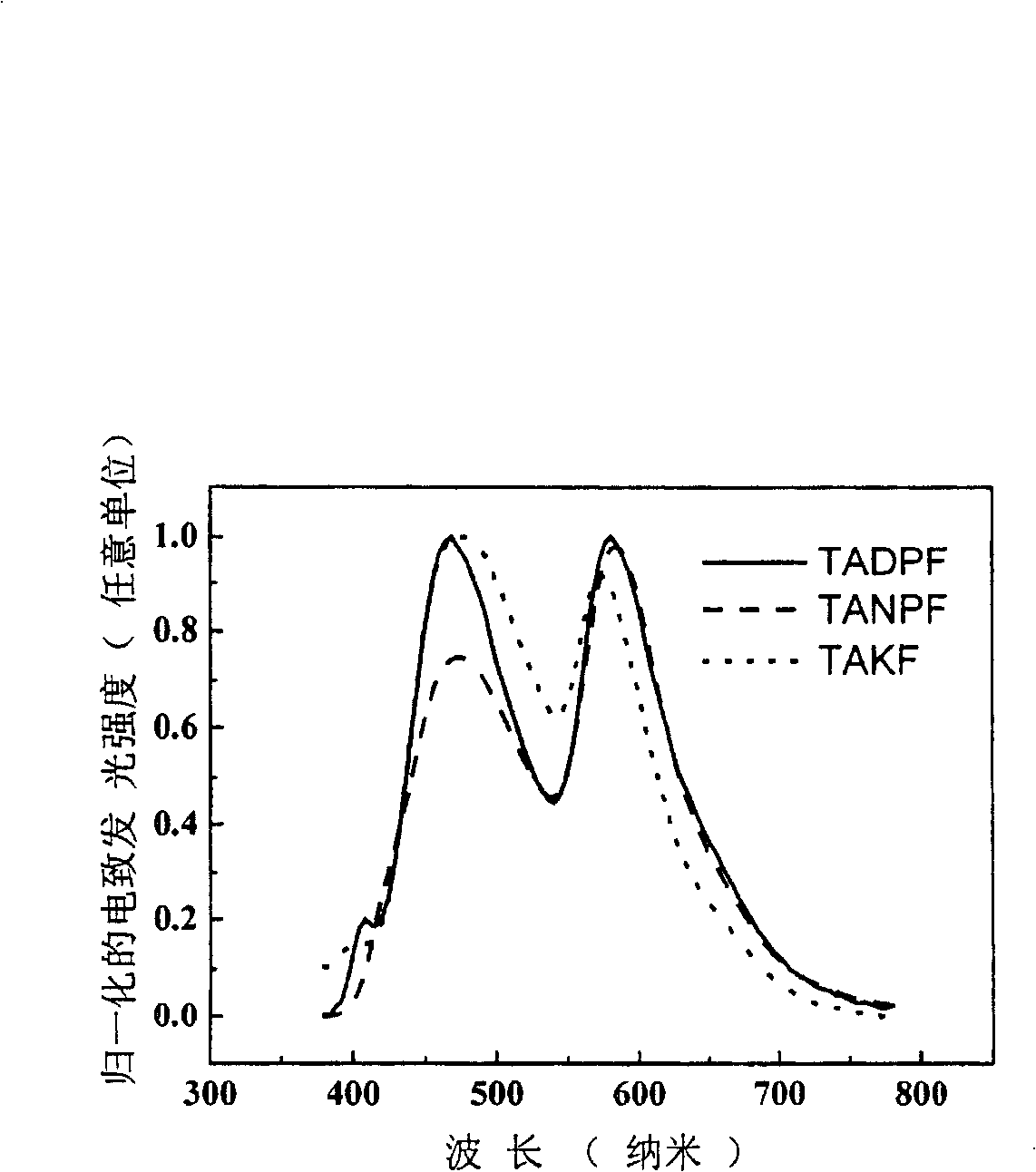

[0049] Organic semiconductor materials for preparing white light OLEDs: the hole transport and luminescent materials are TADPF, TANPF, or TAKF, and their structural formulas are shown in formula 1, formula 2, and formula 3, respectively

[0050]

[0051] Formula 1 Formula 2 Formula 3;

[0052] They can generate electro-excited associations under an electric field, and their synthesis can be found in the literature (K.F.Shao, Y.F.Li, L.M.Yang, Chem.Lett.2005, 34, 1604); the electron transport and light-emitting material is Zn (BTZ) 2 ; The hole-blocking material is TNS; the electron-transporting material is Alq 3 .

[0053] The anode used in the device is ITO, and the cathode is lithium fluoride (LiF) / aluminum (Al), but the cathode is not limited to this, and it can also be lithium, calcium, barium, magnesium, silver, aluminum and other metals.

[0054] Implementation steps:

[0055] The first step: cleaning of ITO glass

[0056]The ITO glass was washed with det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com