Treatment method of copper material production circulating water

A treatment method and circulating water technology, applied in water/sewage treatment, metallurgical wastewater treatment, water treatment parameter control, etc., can solve problems such as electroplating wastewater environmental pollution, surface water, soil pollution, human and other biological hazards, and achieve Environmentally friendly, wide range of applications, and the effect of reducing head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

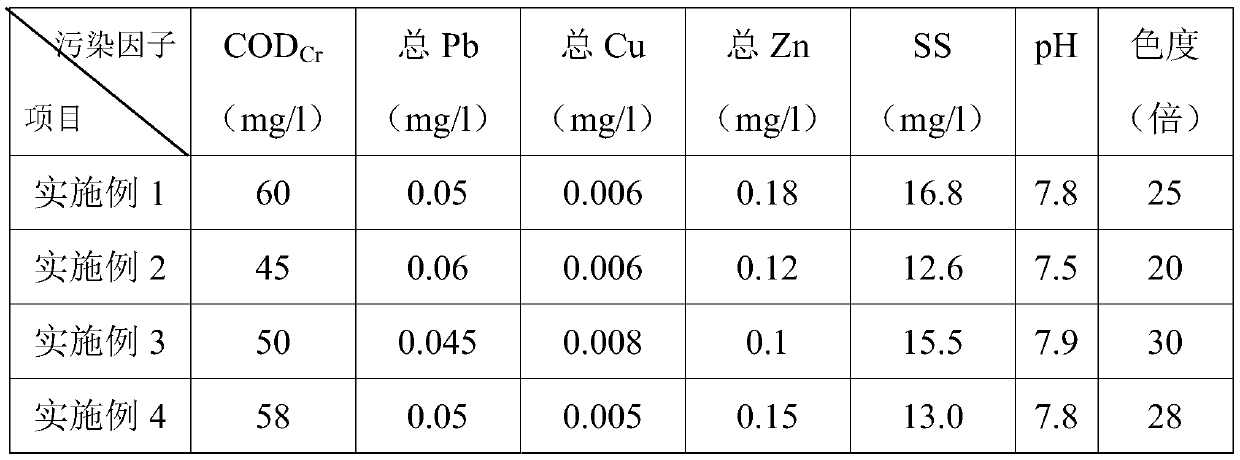

Embodiment 1

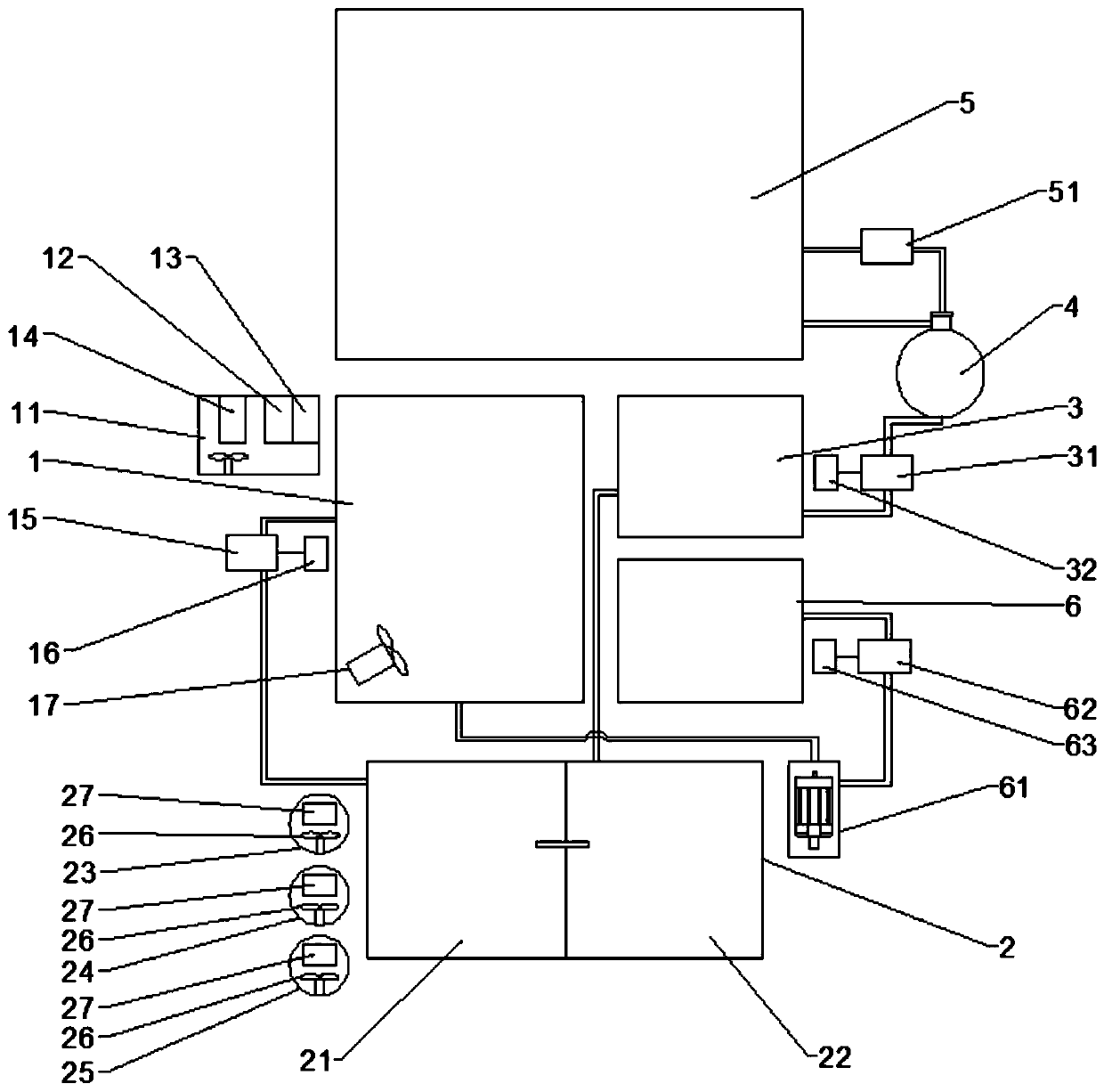

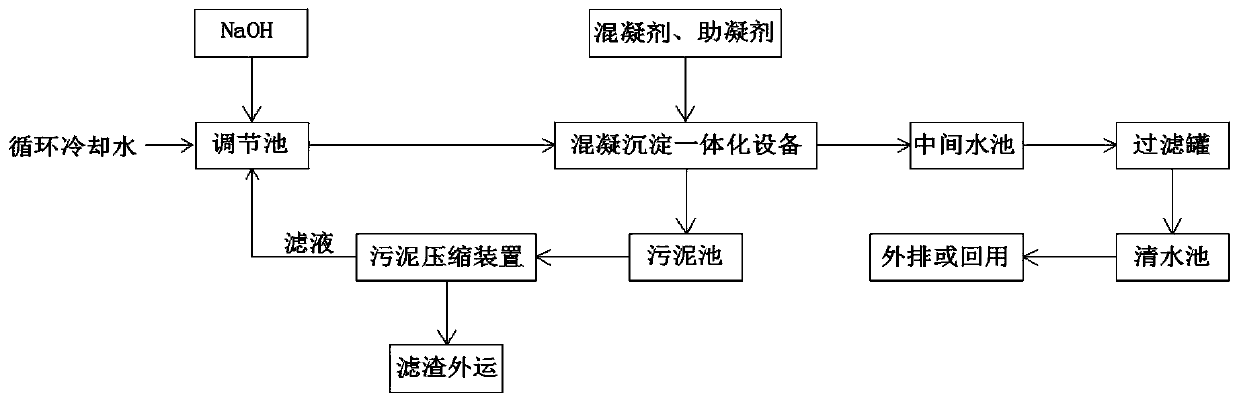

[0043] Such as figure 1 , figure 2 Shown, a kind of copper material produces the processing method of circulating water, comprises the following steps:

[0044] S1. Discharge the circulating water into the adjustment tank 1, the adjustment tank 1 is equipped with an automatic dosing device, including an alkaline medicine barrel 11, a metering pump 12 installed on the alkaline medicine barrel 11, and a pH control system connected to the metering pump 12 , the pH control system includes a pH sensor 13 and a controller 14, the pH sensor 13 detects the pH value of the circulating water in the adjustment tank 1 and feeds back the pH signal to the controller 14, and the controller 14 controls the metering pump 12 to quantitatively add 2wt% sodium hydroxide solution, so that the pH of the circulating water is between 8 and 8.2.

[0045]S2. Pump the circulating water whose pH has been adjusted in step S1 into the coagulation-sedimentation integrated equipment 2 through the submersi...

Embodiment 2

[0050] Such as figure 1 , figure 2 Shown, a kind of copper material produces the processing method of circulating water, comprises the following steps:

[0051] S1. Discharge the circulating water into the adjustment tank 1, the adjustment tank 1 is equipped with an automatic dosing device, including an alkaline medicine barrel 11, a metering pump 12 installed on the alkaline medicine barrel 11, and a pH control system connected to the metering pump 12 , the pH control system includes a pH sensor 13 and a controller 14, the pH sensor 13 detects the pH value of the circulating water in the adjustment tank 1 and feeds back the pH signal to the controller 14, and the controller 14 controls the metering pump 12 to quantitatively add 8.5wt% of hydrogen oxide Sodium solution, so that the pH of the circulating water is between 8.5 and 8.8.

[0052] S2. Use the submersible pump 15 to pump the circulating water whose pH has been adjusted in step S1 into the flocculation reaction tan...

Embodiment 3

[0056] Such as figure 1 , figure 2 Shown, a kind of copper material produces the processing method of circulating water, comprises the following steps:

[0057] S1. Discharge the circulating water into the adjustment tank 1, the adjustment tank 1 is equipped with an automatic dosing device, including an alkaline medicine barrel 11, a metering pump 12 installed on the alkaline medicine barrel 11, and a pH control system connected to the metering pump 12 , the pH control system includes a pH sensor 13 and a controller 14, the pH sensor 13 detects the pH value of the circulating water in the adjustment tank 1 and feeds back the pH signal to the controller 14, and the controller 14 controls the metering pump 12 to quantitatively add 6.5 wt% of hydrogen oxide Sodium solution, so that the pH of the circulating water is 8.2 to 8.5.

[0058] S2. Use the submersible pump 15 to pump the circulating water whose pH has been adjusted in step S1 into the flocculation reaction tank 21 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com