Preparation of manganese-doped willemite yellow fluorescent powder

A yellow phosphor, manganese zinc silicate technology, applied in the field of phosphors, can solve the problems of particle agglomeration, affecting the fluorescence efficiency, non-uniformity, etc., and achieve the effects of stable chemical properties, low reaction temperature, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

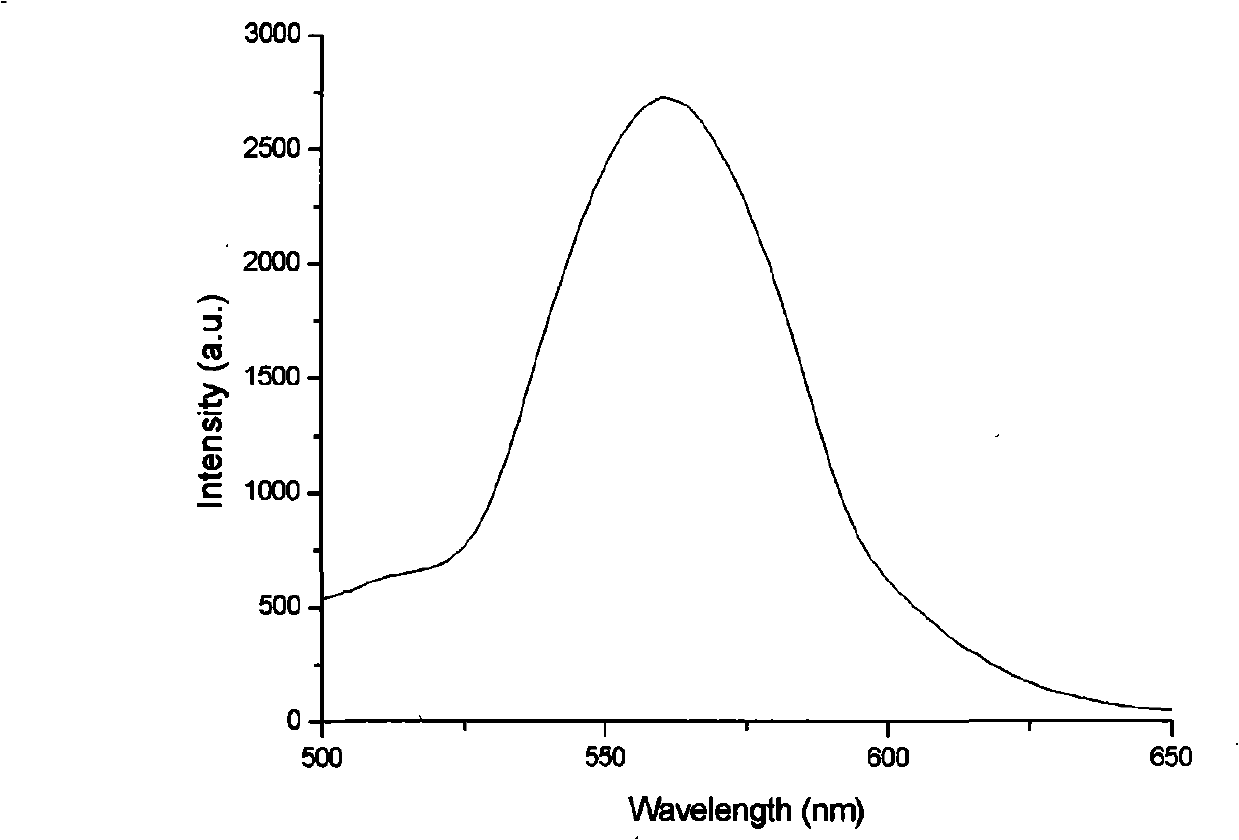

Embodiment 1

[0024] (1) Zinc nitrate, manganese chloride and sodium hydroxide are prepared into 1mol / L, 1mol / L and 2mol / L aqueous solutions respectively with deionized water. (2) Calculated on the basis of 1 mmol of silicon dioxide, according to Zn 1.94 SiO 4 :Mn 0.06 Stoichiometric ratio Weigh silica and measure zinc nitrate and manganese chloride solutions. Zinc nitrate solution, manganese chloride solution, silicon dioxide and ethylene glycol are ultrasonically mixed, and then dropwise added hydrazine hydrate and sodium hydroxide solution, wherein the molar ratio of sodium hydroxide, hydrazine hydrate and zinc nitrate is 3:10: 2. The amount of ethylene glycol and aqueous solution is added at a ratio of 4:1, and the above mixture is further ultrasonically dispersed to form a suspension solution. (3) The suspension was transferred to a reactor and heated at 200°C for 72h. After cooling, wash with water and ethanol, and dry in air. Obtain yellow phosphor Zn 1.94 SiO 4 :Mn 0.06 . T...

Embodiment 2

[0026] (1) Zinc nitrate, manganese chloride and sodium hydroxide are prepared into 1mol / L, 1mol / L and 2mol / L aqueous solutions respectively with deionized water. (2) Calculated on the basis of 1 mmol of silicon dioxide, according to Zn 1.86 SiO 4 :Mn 0.14 Stoichiometric ratio Weigh silica and measure zinc nitrate and manganese chloride solutions. Zinc nitrate solution, manganese chloride solution, silicon dioxide and ethylene glycol are ultrasonically mixed, and then dropwise added hydrazine hydrate and sodium hydroxide solution, wherein the molar ratio of sodium hydroxide, hydrazine hydrate and zinc nitrate is 3:10: 2. The amount of ethylene glycol and aqueous solution is added at a ratio of 4:1, and the above mixture is further ultrasonically dispersed to form a suspension solution. (3) The suspension was transferred to a reactor and heated at 200°C for 72h. After cooling, wash with water and ethanol, and dry in air. Obtain yellow phosphor Zn 1.86 SiO 4 :Mn 0.14 . T...

Embodiment 3

[0028] (1) Zinc nitrate, manganese chloride and sodium hydroxide are prepared into 1mol / L, 1mol / L and 2mol / L aqueous solutions respectively with deionized water. (2) Calculated on the basis of 1 mmol of silicon dioxide, according to Zn 1.80 SiO 4 :Mn 0.20 Stoichiometric ratio Weigh silica and measure zinc nitrate and manganese chloride solutions. Zinc nitrate solution, manganese chloride solution, silicon dioxide and ethylene glycol are ultrasonically mixed, and then dropwise added hydrazine hydrate and sodium hydroxide solution, wherein the molar ratio of sodium hydroxide, hydrazine hydrate and zinc nitrate is 3:10: 2. The amount of ethylene glycol and aqueous solution is added at a ratio of 4:1, and the above mixture is further ultrasonically dispersed to form a suspension solution. (3) The suspension was transferred to a reactor and heated at 200°C for 72h. After cooling, wash with water and ethanol, and dry in air. Obtain yellow phosphor Zn 1.80 SiO4 :Mn 0.20 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com