Method and apparatus for crushing waste tyre

A pulverizer and gear set technology, which is applied in recycling technology, grain processing, mechanical material recycling, etc., can solve the problems of heavy workload and achieve the effects of small extrusion, low heat, and simple and reliable screen structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

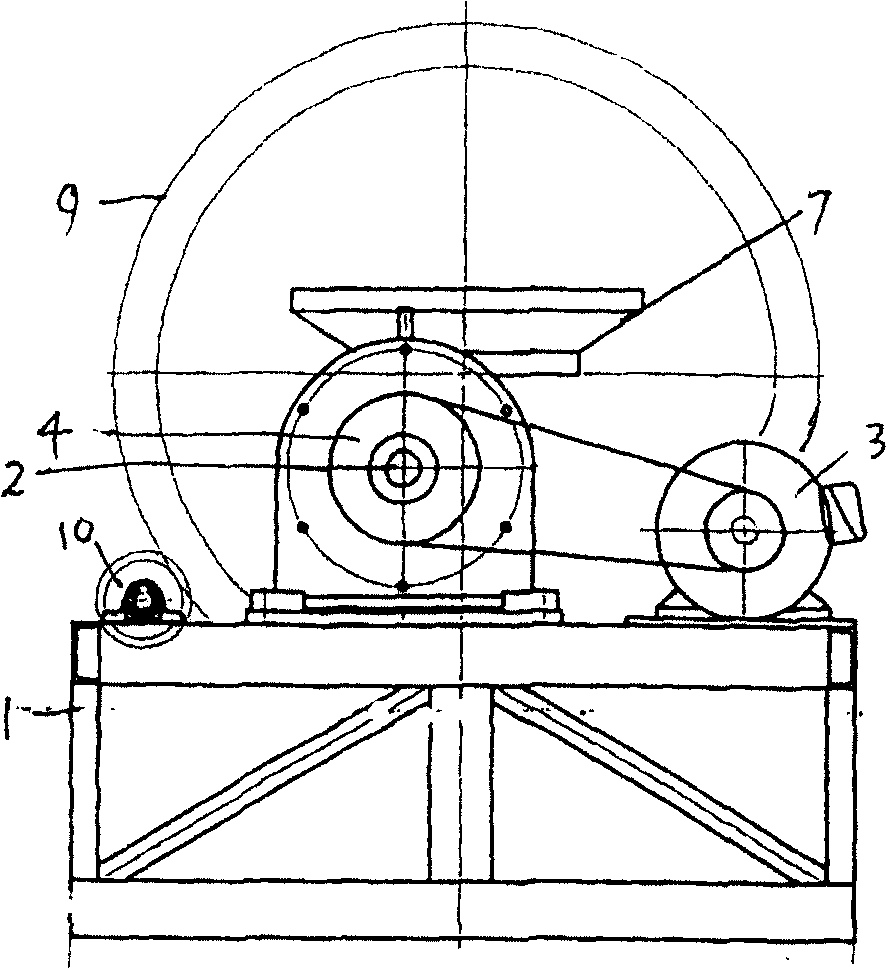

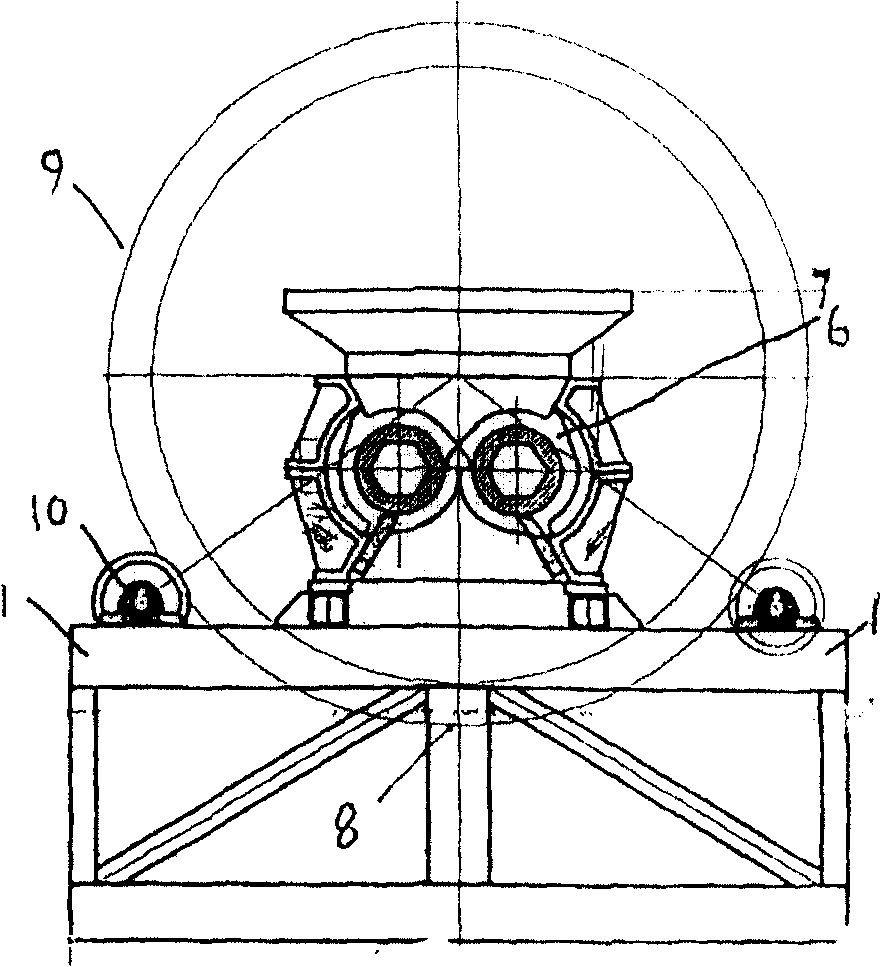

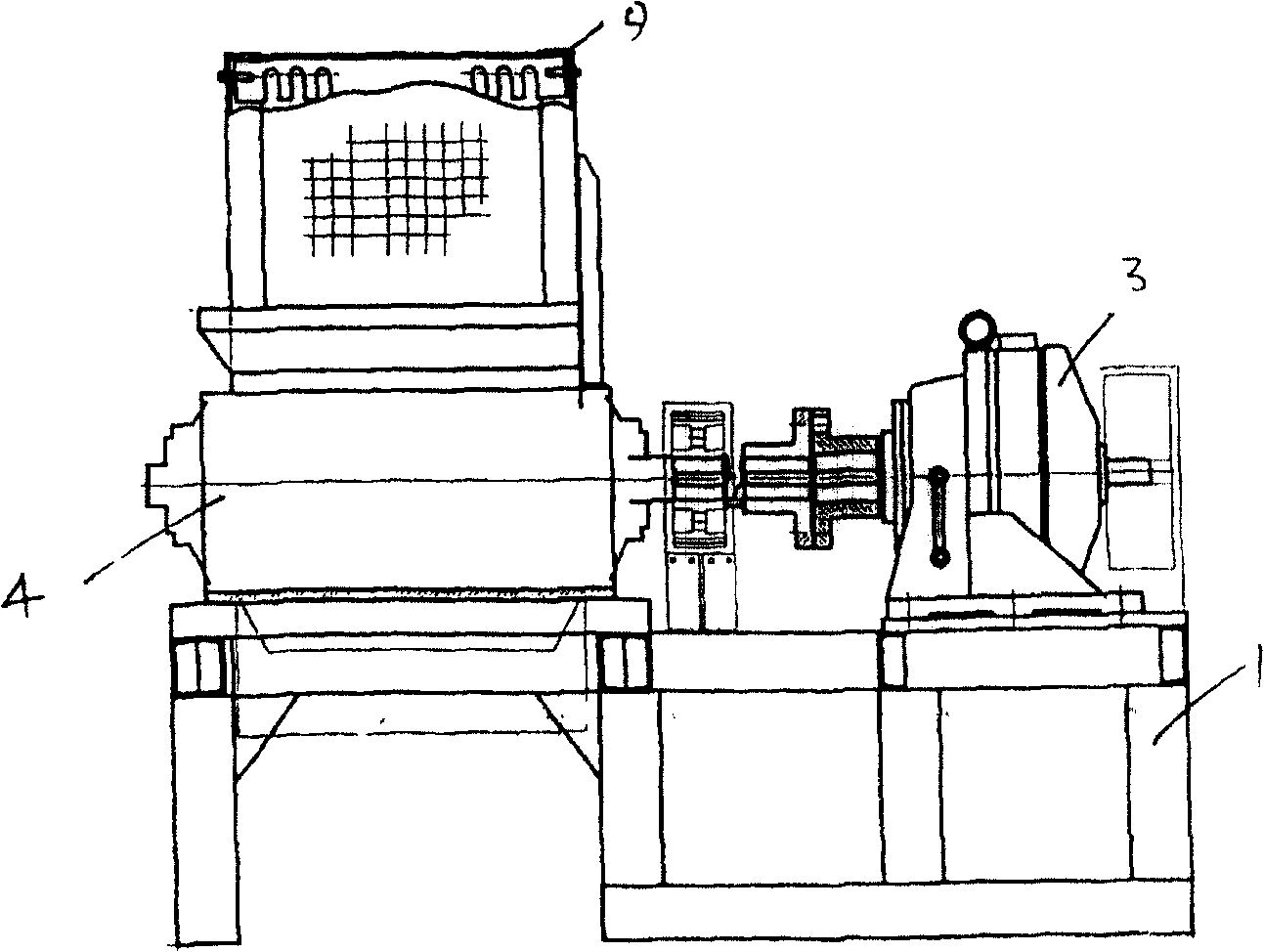

[0022] Referring to the accompanying drawings, the frame shaft seat is provided with two rollers formed by the shaft 5 which is distributed on the sheet cutter 6 according to the inward rotation of the pair of rollers, and the roller shaft is installed on the frame through the bearing seat. The two roller shafts are driven by the motor and the reducer (generally, the two rollers are driven at the same time); the present invention is provided with two rollers distributed according to the inward rotation of the pair of rollers, and the surface of at least one of the rollers is There are a number of sheet-like knives arranged vertically on the shaft, and the sheet-like knives on the two rollers are staggered (the gap between the two knives on the same roll is the protruding knives of the other roll) ), the right-angle knife edge between the staggered distribution of sheet-shaped cutters constitutes the cutting edge to cut rubber, and the width is the same as the width of the blade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com