Single beam magneto-optic well system

A magneto-optical trap and single-beam technology, applied in the field of magneto-optical trap systems, can solve the problems of difficult adjustment of the optical path, complex structure, and large device volume, and achieve the effects of increasing practicability, small size, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

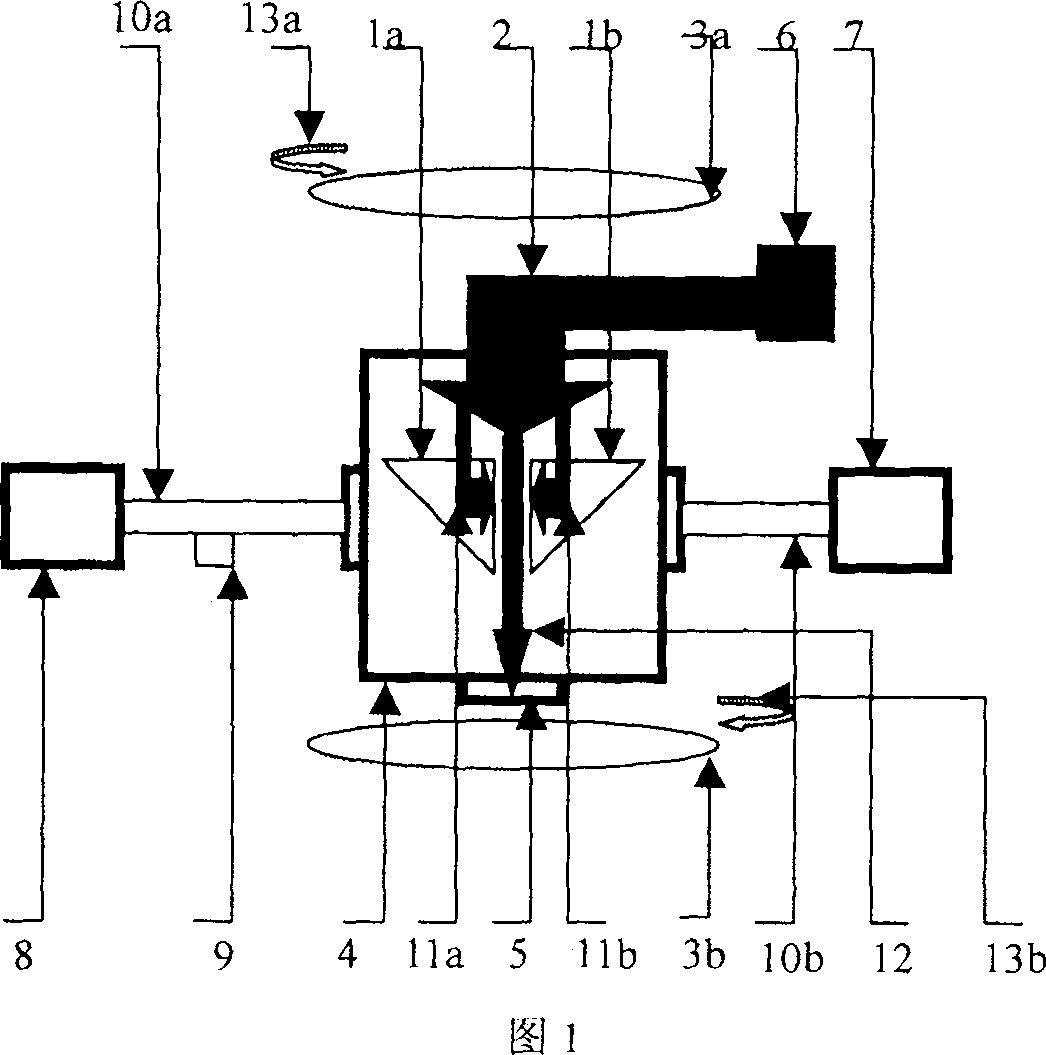

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] 1. The vacuum pump (8) is connected with a vacuum conduit (10a). The vacuum pump (8) includes a molecular pump and a mechanical pump, as well as bellows used for connecting the vacuum system. The ion pump (7) is connected with another vacuum conduit (10b). The ion pump (7) is a small sputtering ion pump. Both the vacuum conduit (10a) and the vacuum conduit (10b) are connected to the metal air chamber (4), and the connected windows are windows facing each other. The vacuum pump (8), that is, the molecular pump and the mechanical pump are used to pre-pump the entire device system. After the pre-pumping, the molecular pump and the mechanical pump can be turned off, and the ion pump (7) can be turned on to make the entire device system vacuum is maintained.

[0013] 2. The vacuum conduit (10a) is connected to the sample bubble (9), and the vacuum conduit (10a) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com