Anti-seepage freeze gel artificial prosthesis and method for manufacturing the same

A technology of artificial prosthesis and manufacturing method, which is applied in the field of medical materials to achieve the effects of good practical value, high elasticity, and enhanced leakage prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

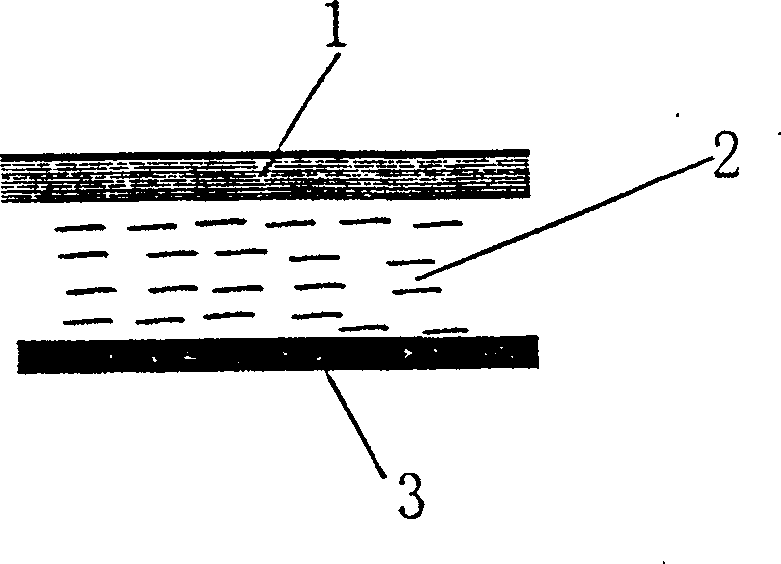

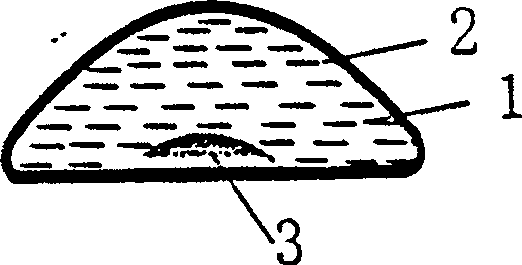

[0033] Embodiment 1, the making of circular smooth surface anti-leakage artificial breast prosthesis (see figure 2 )

[0034] (1) Make material A of low-temperature vulcanized polysiloxane and chloroplatinic acid, and material B of polysiloxane and hydrogen-containing silicone oil and dissolve them in petroleum ether to make a 5% solution and mix them evenly at 1:1. The round mold is poured, vulcanized at 80°C for 3 hours, and then the second layer is poured after solidification and cooling. A total of 4 layers are poured, of which 10% anti-seepage agent is added to the inner 2 layers. After all the pouring and solidification, cooling and demoulding, Make capsule body 1 for subsequent use;

[0035] (2) Mix the above-mentioned polysiloxane material A and material B according to the ratio of 1:1, mix repeatedly on the mixer, heat press (120°C×10 minutes) with a flat mold, and then add the polysiloxane in (1). Pouring two layers of silicone rubber solution with anti-seepage ag...

Embodiment 2

[0040] Embodiment 2, the making of conical velvet anti-leakage artificial breast prosthesis (see figure 2 )

[0041] (1) Make material A of low-temperature vulcanized polysiloxane and chloroplatinic acid, and material B of polysiloxane and hydrogen-containing silicone oil and dissolve them in petroleum ether to make an 8% solution and mix them evenly at 1:1. Conical mold for pouring, vulcanized at 100°C for 3 hours, solidified and cooled, then poured the second layer, the third layer..., a total of 6 layers, of which 15% anti-seepage agent was added to the inner 3 layers, and all poured After solidification and cooling, the demoulding is ready for use;

[0042] (2) Mix the above-mentioned polysiloxane material A and material B according to the ratio of 1:1, mix repeatedly on the mixer, heat press (120°C×6 minutes) with a flat mold, and then add the polysiloxane in (1). Three layers of silicone rubber solution with anti-seepage agent are poured, and after vulcanization, it i...

Embodiment 3

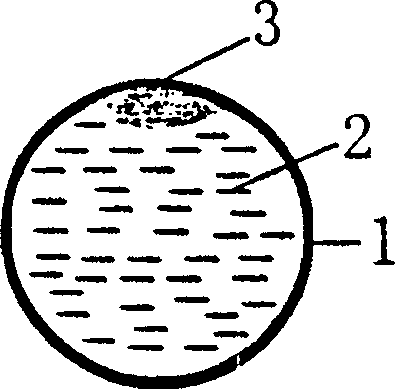

[0047] Embodiment 3, the making of gel anti-leakage artificial testis (see Figure 4 )

[0048] (1) Dissolve low-temperature vulcanized polysiloxane material A and material B with petroleum ether (acetone) respectively to make a 6% solution and mix them evenly at a ratio of 1:1, then pour them into testicle molds, vulcanize at 80°C for 4 hours, and cure After cooling, pour the second layer, and pour 4 layers in total, of which 10% anti-seepage agent is added to the inner 2 layers. After all the pouring is solidified, the mold is cooled and demoulded, and the capsule body 1 is prepared for use;

[0049] (2) Mix the low-temperature vulcanized polysiloxane material A and material B in a ratio of 1:1, mix repeatedly on the mixer, and use a flat mold for hot pressing (120°C × 8 minutes) to form, and then use (1) Pouring two layers of silicone rubber solution with anti-seepage agent in it, vulcanized as cover plate 3 for later use;

[0050] (3) The capping machine 3 is bonded to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com