Ionic conductor rubber composition and ionic conductor roller using the composition

A rubber composition, ion-conductive technology, applied in the field of ion-conductive rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

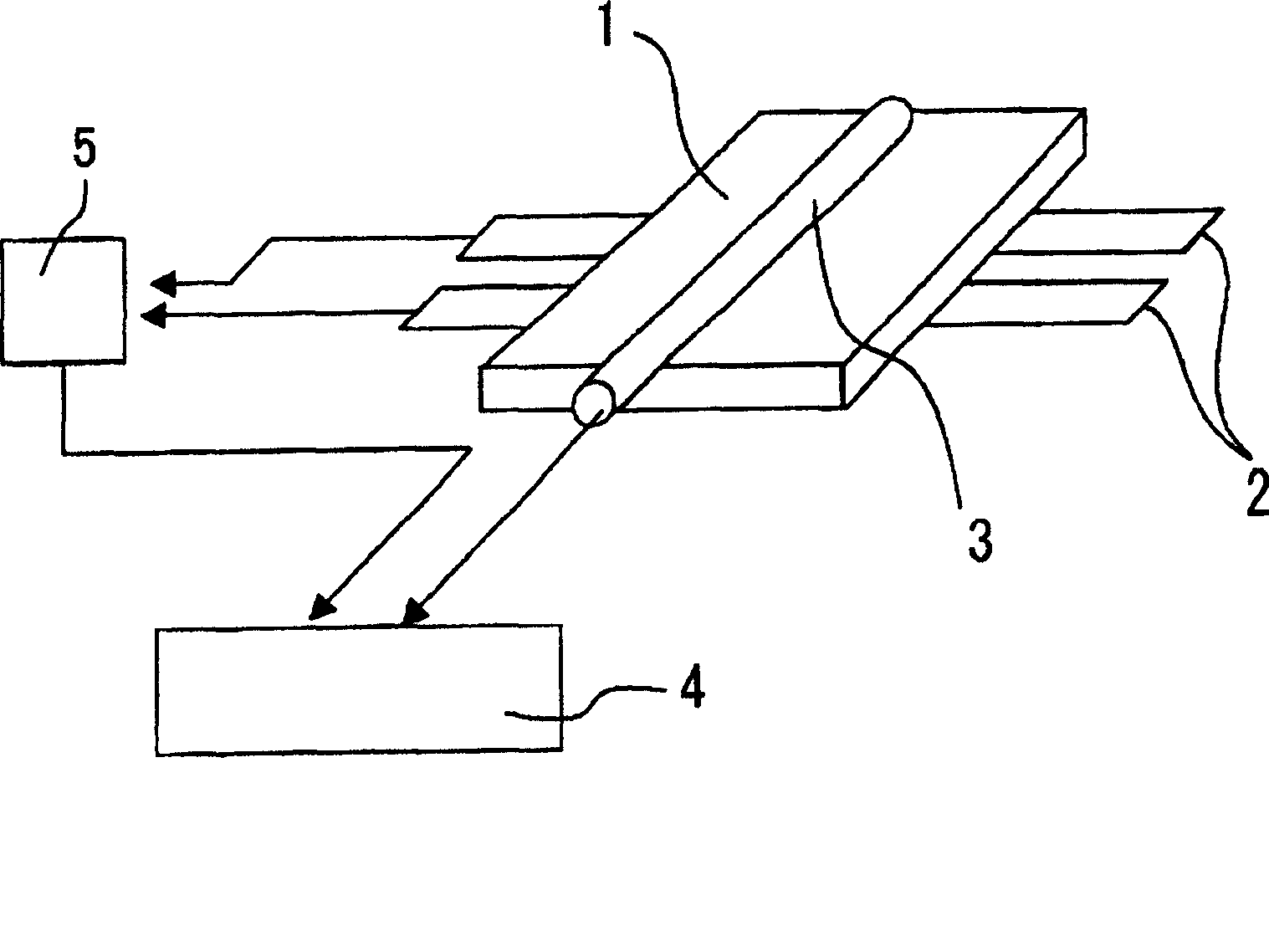

Image

Examples

Embodiment 1

[0106] By (A) 11 mass parts 1,3,5,7-tetramethyl-1,3,5,7-tetravinyl cyclotetrasiloxane, (B) 100 mass parts compound G-1 (so that the composition The number of moles of the Si—H group in the part (B) is about 1.0 moles relative to the vinyl group of each mole of the component (A), (C) 2 parts by mass of chloroplatinic acid-vinylsiloxane complex (platinum metal content: 0.5% by mass), 0.3 parts by mass of 1-ethynyl cyclohexanol, (D) 2 parts by mass of lithium bis(trifluoromethanesulfonyl)imide (equivalent to components (A) and (B) 1.8% by mass of the total) and (E) 5 parts by mass of pentaerythritol tetrakis [3-(3,5-di-tert-butyl-4-hydroxyl phenyl) propionate] (equivalent to components (A) and (B) 4.5% by mass of the total) were uniformly mixed together to prepare Composition 1. Composition 1 obtained above was cured by heating at 120° C. for 10 minutes to produce cured product 1 with a hardness of 40. The hardness was measured by preparing a 6 mm-thick sheet-shaped cured produ...

Embodiment 2

[0108] In addition to using (D) 2 mass parts lithium bis(trifluoromethanesulfonyl)imide in Example 1 with 10 mass parts ethoxyethylmethylpyrrolidinium bis(trifluoromethanesulfonyl)imide (equivalent to Composition 2 was prepared in the same manner as in Example 1 except that 9.0% by mass of the sum of components (A) and (B)) was replaced. The above-mentioned Composition 2 was cured by heating at 120° C. for 10 minutes to produce a cured product 2 with a hardness of 40.

Embodiment 3

[0110] By adding 100 parts by mass of (A) to 6.7 mol% CH 2 =CH(CH 3 ) 2 SiO 1 / 2 Unit, 63.3 mol% (CH 3 ) 2 SiO units and 30 mol% (C 6 h 5 ) 2 The viscosity of SiO unit is the organopolysiloxane of 0.7Pas, (B) 43 mass parts compound G-1 (so that the molar number of component (B) Si-H group is relative to the ethylene of each mole component (A) base is about 1.0 mol), 0.25 parts by mass of 1-ethynyl cyclohexanol, (C) 2 parts by mass of chloroplatinic acid-vinylsiloxane complex (platinum metal content: 0.5 mass%), (D)2 Parts by mass of lithium bis(trifluoromethanesulfonyl)imide (equivalent to 1.4% by mass of the sum of components (A) and (B)) and (E) 1 mass part of octadecyl alcohol-3-(3,5-di Tert-butyl-4-hydroxyphenyl)propionate (corresponding to 0.7% by mass of the sum of components (A) and (B)) was uniformly mixed together to prepare Composition 3. The above composition 3 was cured by heating at 120° C. for 10 minutes to produce a cured product 3 with a hardness of 17....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com