Dielectric ceramic and laminated ceramic capacitor

A dielectric and porcelain technology, applied in the field of laminated ceramic capacitors, can solve the problems of satisfactory, low-temperature load test life characteristics, reduction, and large insulation resistance reduction, etc., to ensure insulation, high-temperature load life, and high insulation Effects of Resistance, High Insulation, and High Temperature Load Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091]

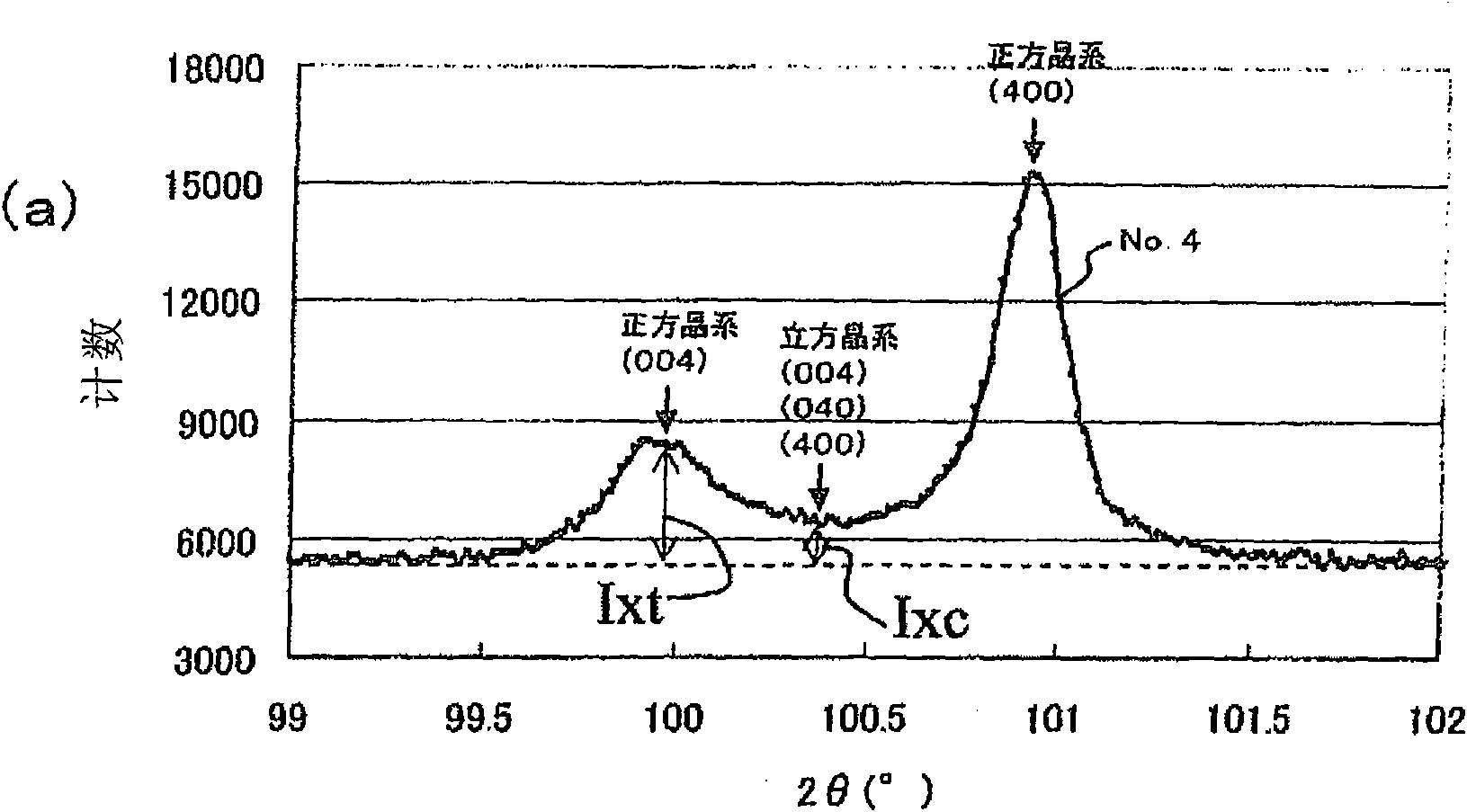

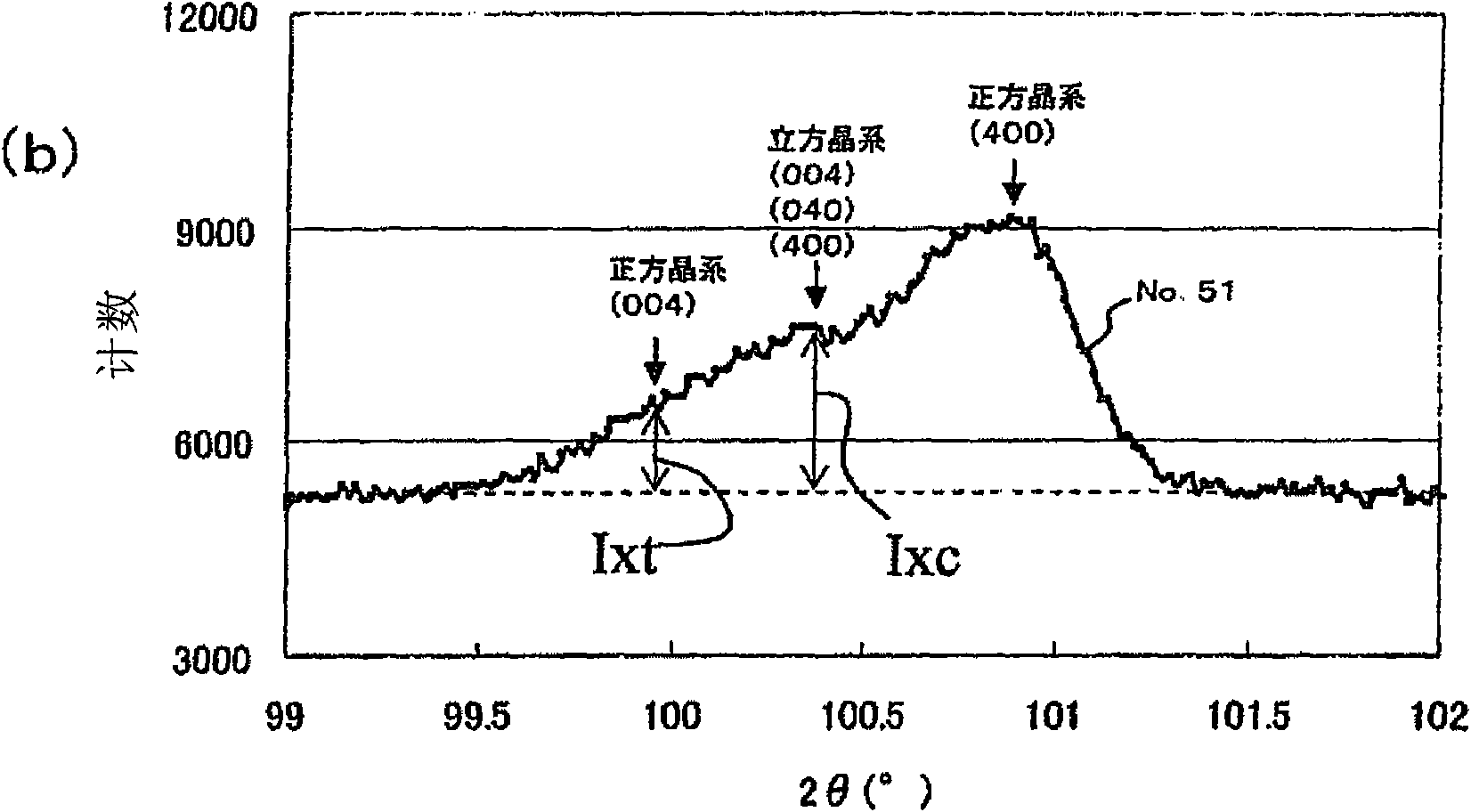

[0092] First, as raw material powders, prepare BT powder, BCT powder (the composition is (Ba 1-x Ca x )TiO 3 , X=0.05), MgO powder, Y 2 o 3 Powder, Dy 2 o 3 Powder, Ho 2 o 3 Powder, Er 2 o 3 Powder, Tb 4 o 7 Powder (second rare earth element), MnCO 3 Powder and V 2 o 5 Powder, BT powder and BCT powder were mixed in equimolar ratios, and various powders of additives were mixed in the ratios shown in Tables 1, 2 and 3. For these raw material powders, materials with a purity of 99.9% were used. In addition, the average particle size of BT powder and BCT powder was set to 0.1 μm for sample Nos. 1-1 to 49, 52, 53, and 56 to 90. A material with an average particle diameter of 0.25 μm was used, and a material with an average particle diameter of 0.12 μm was used for Sample Nos. 1-54 and 55. MgO powder, Y 2 o 3 Powder, Dy 2 o 3 Powder, Ho 2 o 3 Powder, Er 2 o 3 Powder, Tb 4 o 7 Powder, MnCO 3 Powder and V 2 o 5 As the powder, a material with an ...

Embodiment 2

[0164] Then, in addition to sample Nos. 1-1 to 10, 12 to 16, 18 to 34, 36 to 40, 42 to 44, 46, 47, 52 to 65, 68 to 78 and 80 shown in Example 1 In each composition of ~90, 0.35 mol of Yb was added 2 o 3 Except for the powder, a sample was prepared by the same method as in Example 1, and the composition of the dielectric ceramic, the ratio of X-ray diffraction intensity, the average particle size of the crystal grains, and the dielectric ceramic were measured and evaluated by the same method as in Example 1. Relative permittivity of porcelain, dielectric loss, insulation resistance, temperature characteristics of relative permittivity, life characteristics in high temperature load test (samples 2-1 to 78).

[0165] In addition, in addition to the composition of sample No. 1-30 shown in Example 1, Yb 2 o 3 In terms of 0 to 0.9 moles of ytterbium, except that the calcination temperature was set at 1170°C, samples were produced by the same method as in Example 1, and the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com