Dielectric ceramic and laminated ceramic capacitor

A dielectric and ceramic technology, applied in the field of laminated ceramic capacitors, can solve the problems of large insulation resistance voltage dependence and difficulty in improving the life characteristics of high-temperature load tests, etc., and achieve superior life characteristics, high insulation, and high dielectric constant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

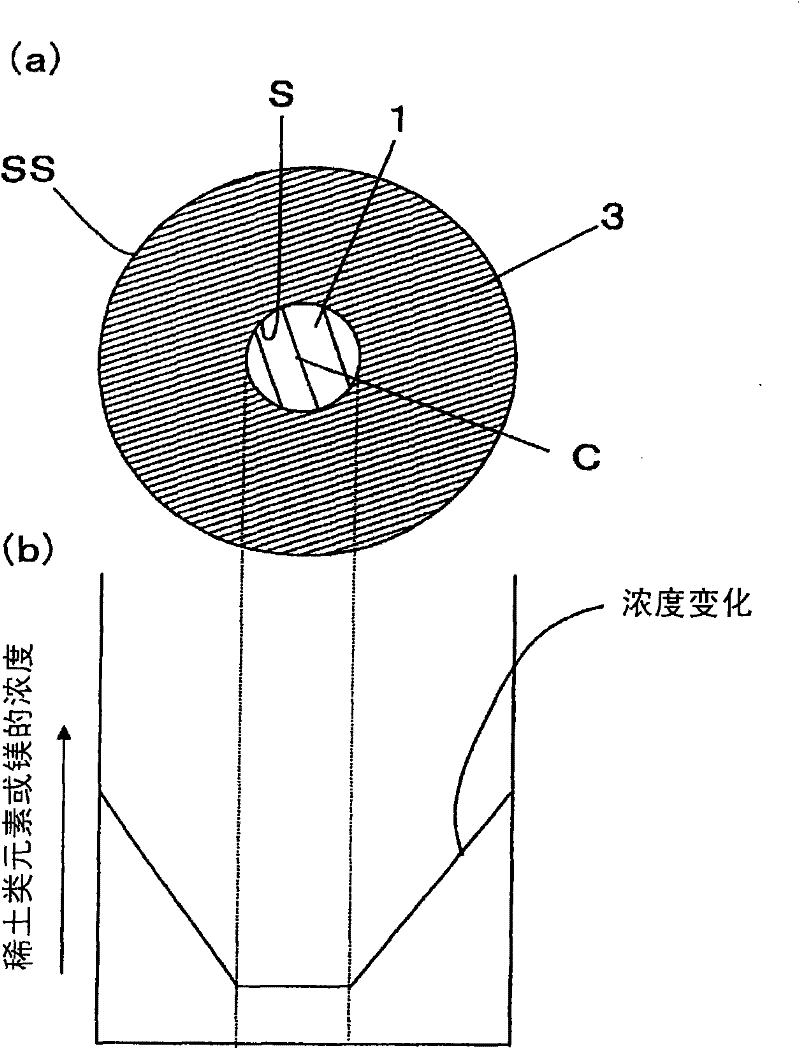

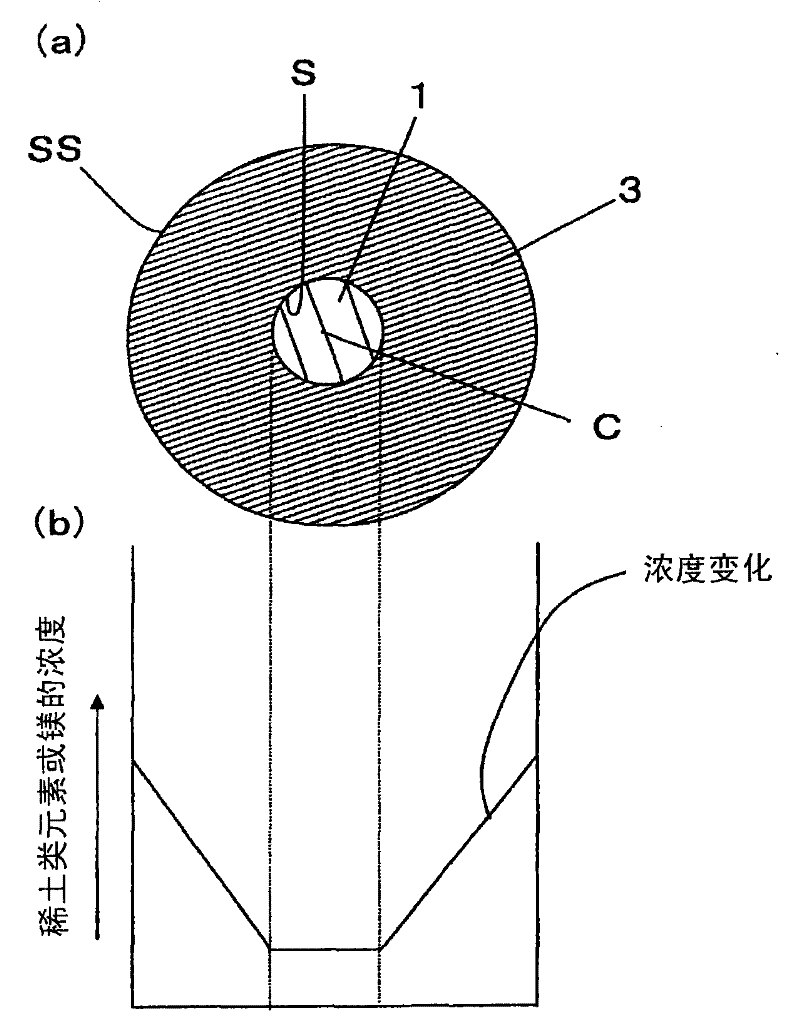

[0020] The dielectric porcelain of the present invention has: essentially a core-shell structure, with barium titanate as the main component, calcium, vanadium, magnesium, manganese, and at least one selected from yttrium, dysprosium, holmium, erbium and terbium A crystal grain of a core-shell structure of a rare earth element; and a grain boundary phase existing between the crystal grains, in which the calcium concentration is 0.4 atomic % or more, and, relative to the constituents of the titanium The total amount of barium and calcium in barium acid is 100 moles, expressed as V 2 o 5 Contains 0.1 to 0.2 mol of vanadium in conversion, 0.55 to 0.75 mol of magnesium in MgO conversion, and RE 2 o 3 It contains 0.55 to 0.75 moles of at least one rare earth element selected from yttrium, dysprosium, holmium, erbium, and terbium in terms of conversion, and contains 0.25 to 0.6 moles of manganese in conversion to MnO.

[0021] In addition, in the dielectric ceramic of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com