Hard-coated antiglare film and method of manufacturing the same

A manufacturing method and anti-glare technology, applied in coating, nonlinear optics, optics, etc., can solve problems such as not being able to obtain sufficient hardness, achieve good anti-glare effect, prevent reflection of external light, etc., high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

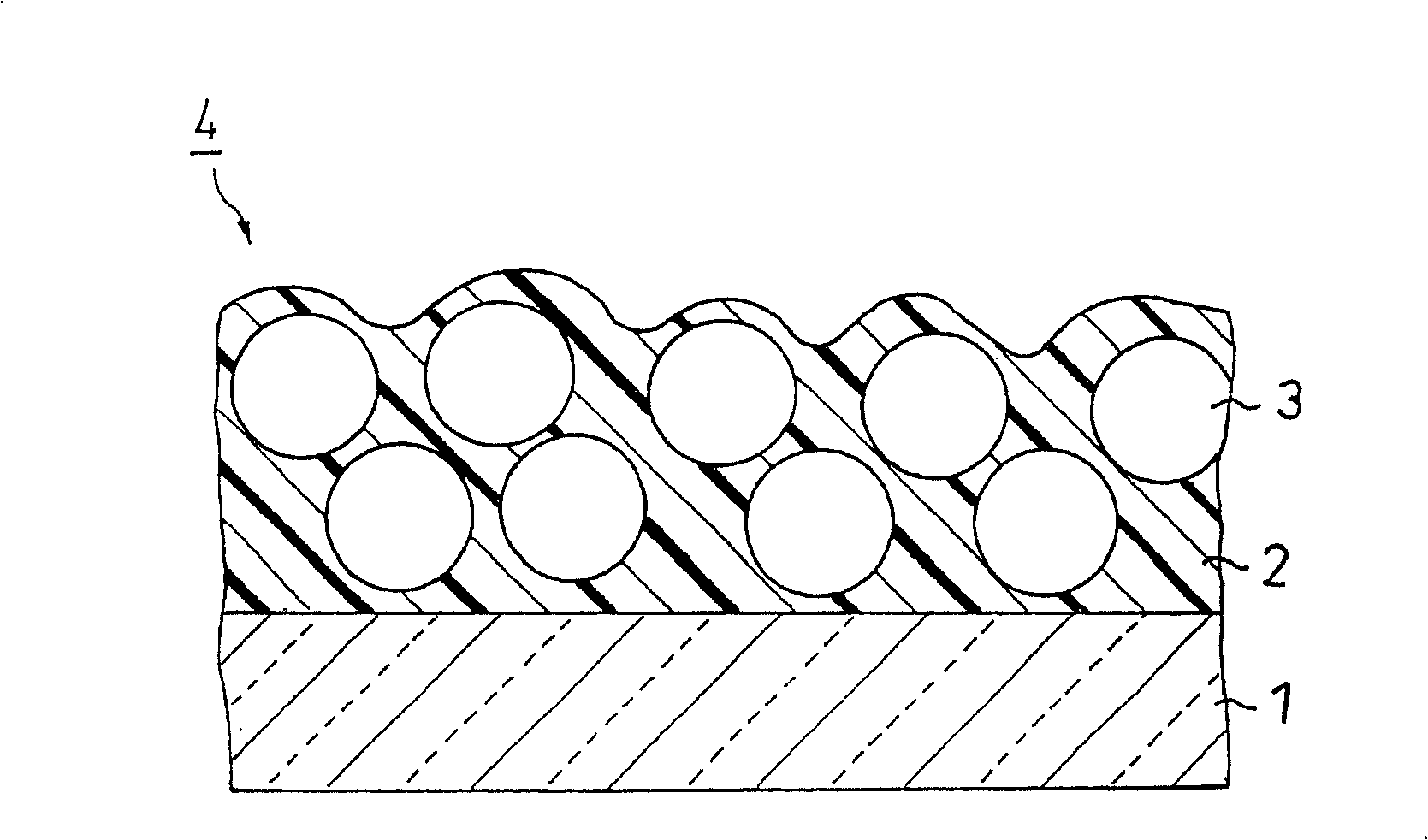

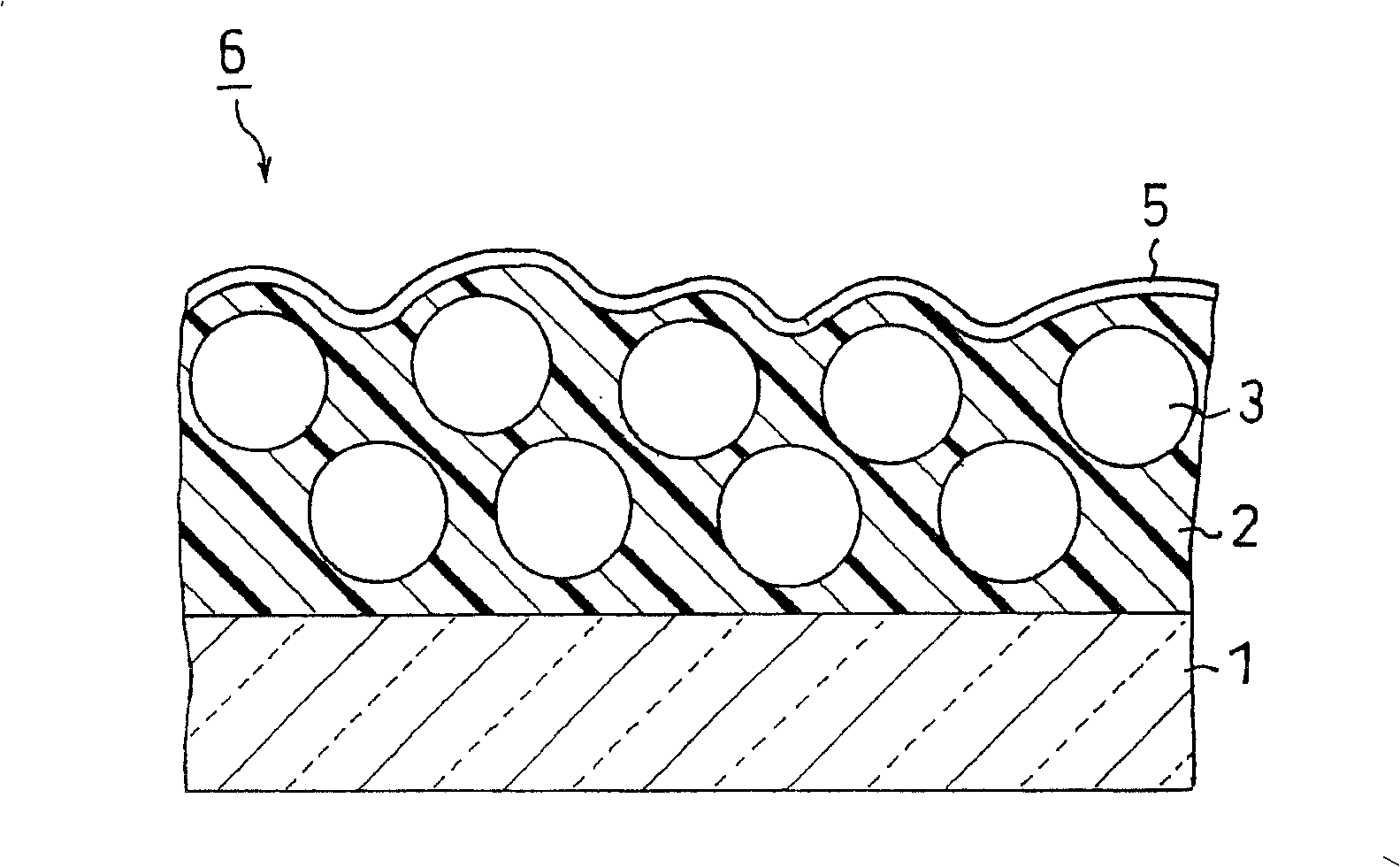

Image

Examples

Embodiment 1

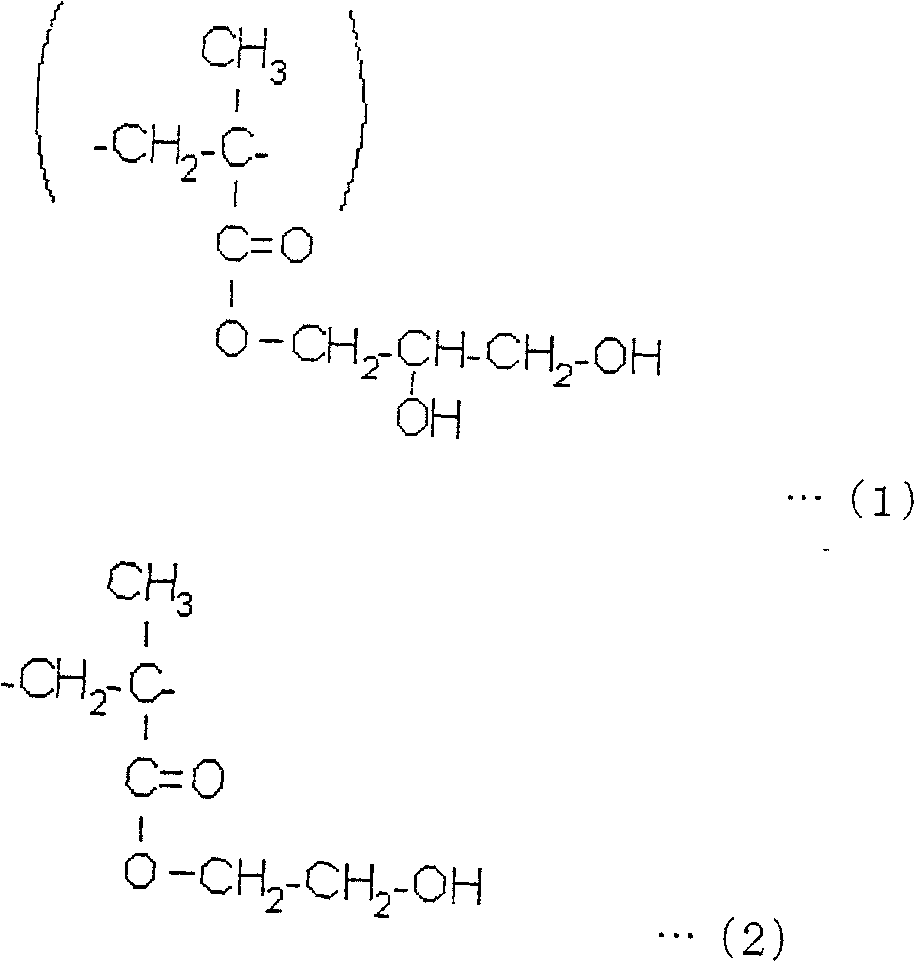

[0174] 100 parts of urethane acrylate composed of pentaerythritol-based acrylate and hydrogenated xylene diisocyanate are blended as urethane acrylate (hereinafter, component A), and polyol (meth)acrylate (hereinafter, B Components) of dipentaerythritol hexaacrylate (hereinafter, B1 component (monomer)) 49 parts, pentaerythritol triacrylate (hereinafter, B2 component (monomer)) 24 parts, and pentaerythritol tetraacrylate (hereinafter, B3 component (monomer) )) 41 parts, as a (meth)acrylic polymer (hereinafter, C component) having an alkyl group containing two or more hydroxyl groups (meth) having a 2-hydroxyethyl group and a 2,3-dihydroxypropyl group Acrylic polymer (manufactured by Dainippon Ink Chemical Industry Co., Ltd., trade name: PC1097) 59 parts. And then, by the mixed solvent that the mixing ratio of butyl acetate and ethyl acetate is 55:45 (relative to the ethyl acetate ratio of total solvent is 45%), dilute the PMMA particle ( Refractive index: 1.49) 30 parts, reac...

Embodiment 2

[0177] In this example, except that the addition amount of PMMA particles was changed to 15 parts, the same method as in Example 1 was used to produce an anti-glare hard-coat film.

Embodiment 3

[0179] In this embodiment, 30 parts of PMMA particles (refractive index: 1.49) with an average particle diameter of 15 μm are added, and the solid content concentration is changed to 35%. Glare hard coat film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com