Manufacturing technique for painting automobiles

A production process and coating technology, which is applied to the metal material coating process, the device for coating liquid on the surface, coating, etc., can solve the problems of not being able to produce in large quantities, so as to improve the production cycle and shorten the coating cycle , the effect of smooth production beat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

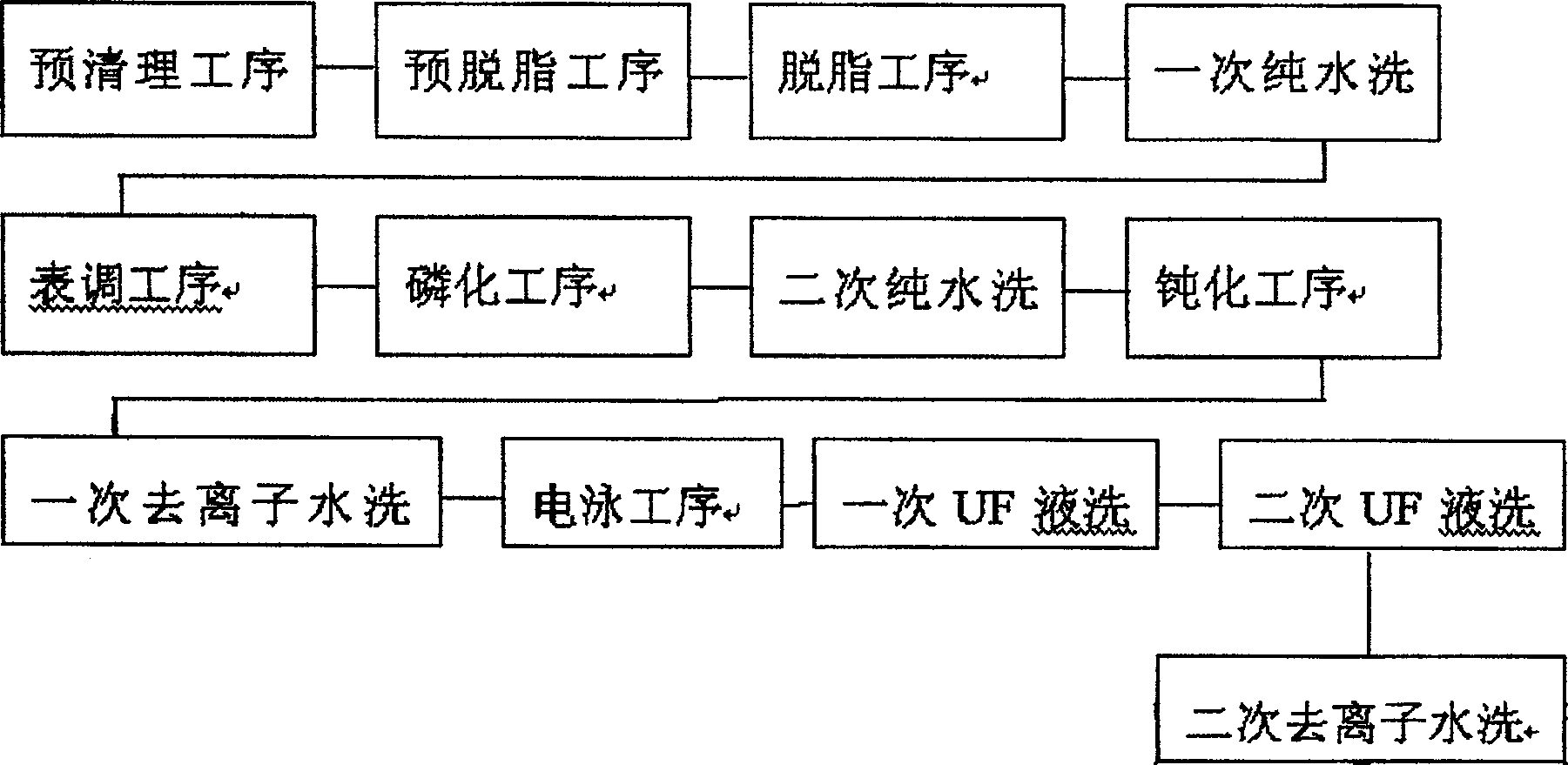

[0013] like figure 1 As shown, the flow process of the coating production process of the present invention is: from pre-cleaning process--pre-degreasing process--degreasing process--primary pure water washing process--surface adjustment process--phosphating process--secondary pure water washing process- -passivation process-one deionized water washing process-electrophoresis process-one UF liquid washing process-two UF liquid washing process-two deionized water washing process.

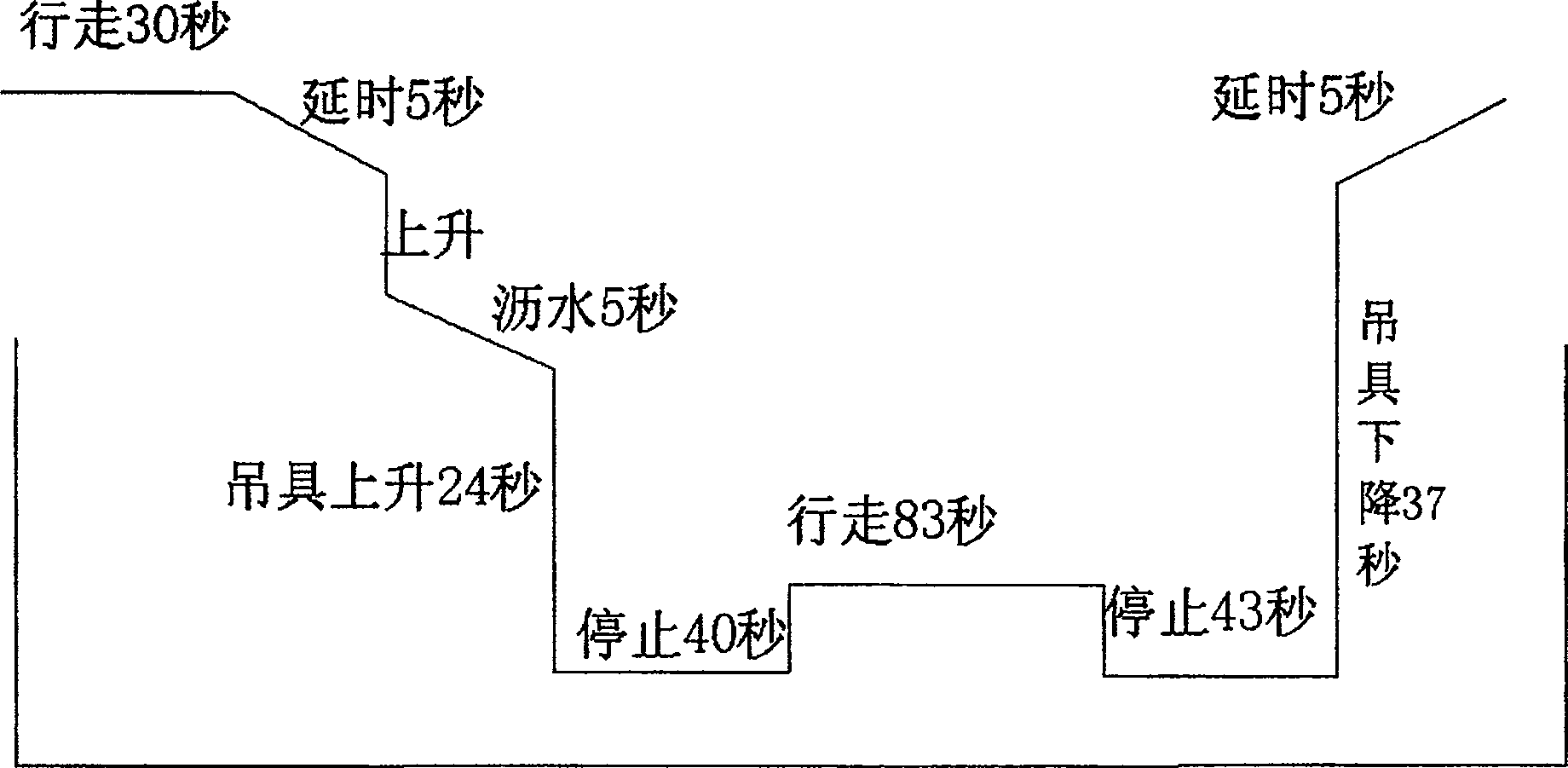

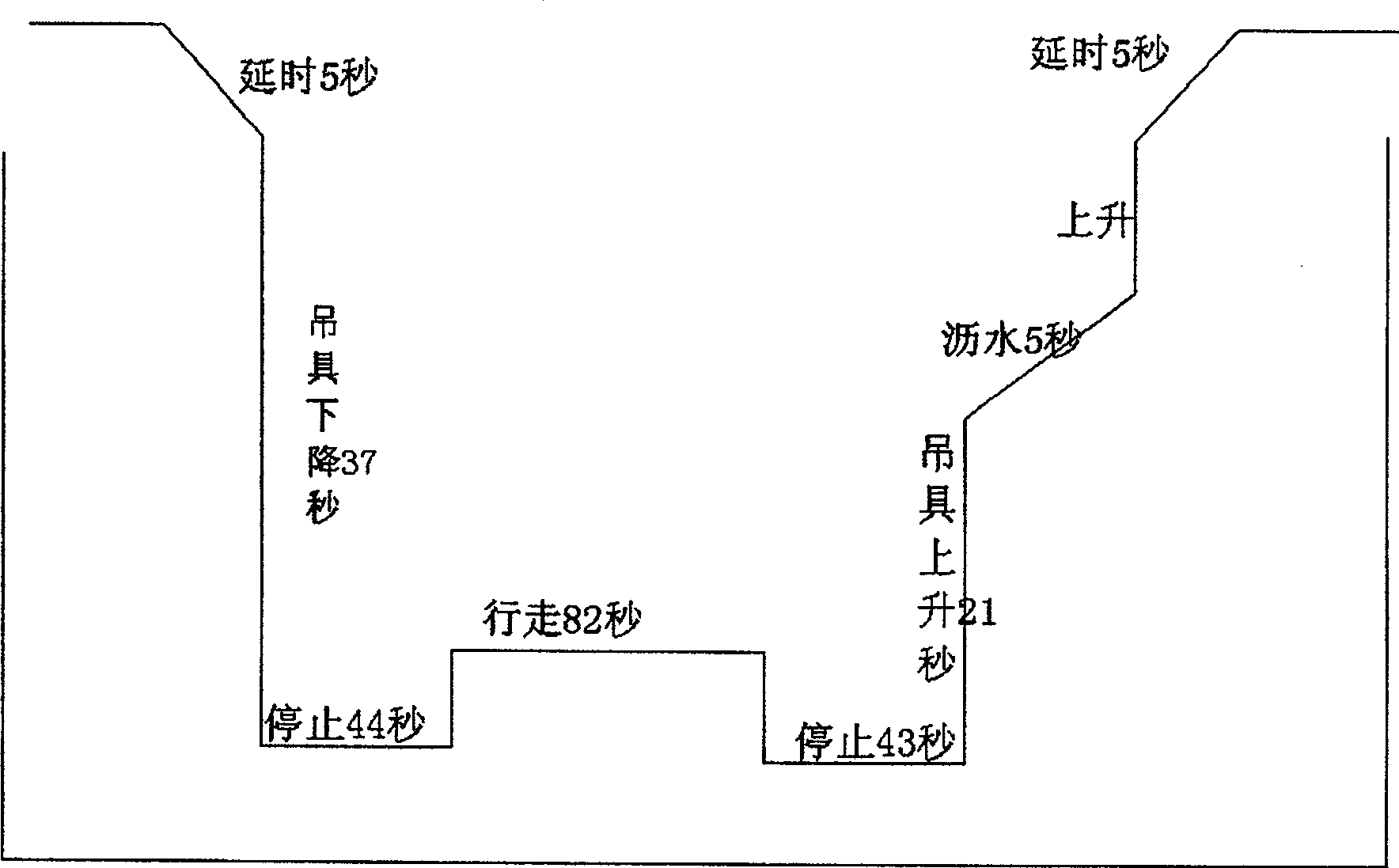

[0014] like figure 2 Shown: a kind of automobile coating production process provided by the present invention, including pre-cleaning process, pre-degreasing process, degreasing process, primary pure water washing process, surface adjustment process, phosphating process, secondary pure water washing process, passivation process, A deionized water washing process, an electrophoresis process, a UF liquid washing process, a second UF liquid washing process, and a second deionized water washing process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com