Method of increasing gas production rate of sewage gas fermentation using xylanase

A technology of xylanase and biogas fermentation, applied in fermentation, waste fuel, etc., can solve problems such as inference limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

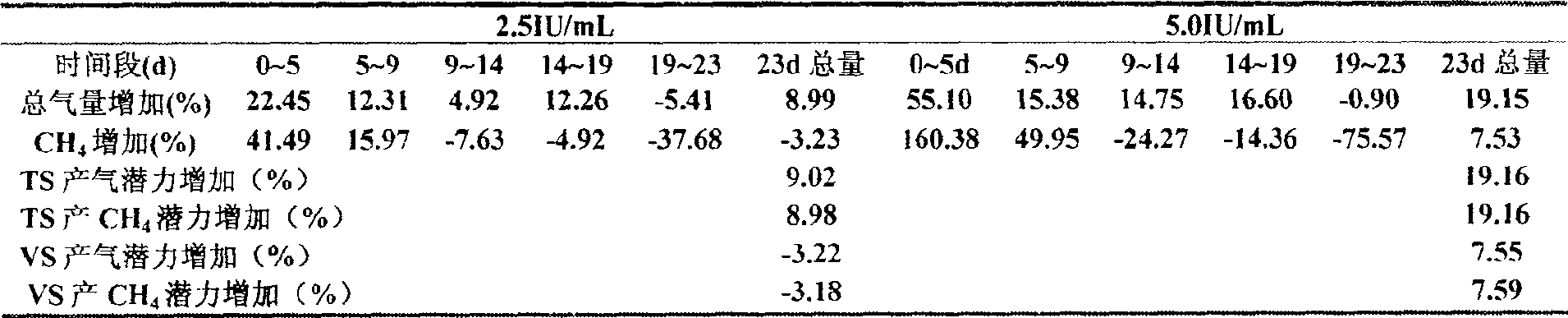

Examples

Embodiment

[0036] (1) The method that xylanase is used for the start-up of new pool

[0037] Start the biogas fermentation according to the conventional biogas fermentation ingredients, and calculate the amount of xylanase added based on the actual volume of fermentation, which is 0.58IU / mL (87BU / mL). In the feeding operation, when the material is fed to 1 / 2 to 2 / 3, the required input xylanase is absorbed and dissolved with water and then poured into the pool, and then the rest of the material is used to seal the pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com