Manufacture method of high resolution self-supporting totally hollowed-out transmission grating

A high-resolution, transmission grating technology, applied in the direction of diffraction grating, photosensitive material processing, microlithography exposure equipment, etc., can solve the problems of inability to produce high aspect ratio graphics and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

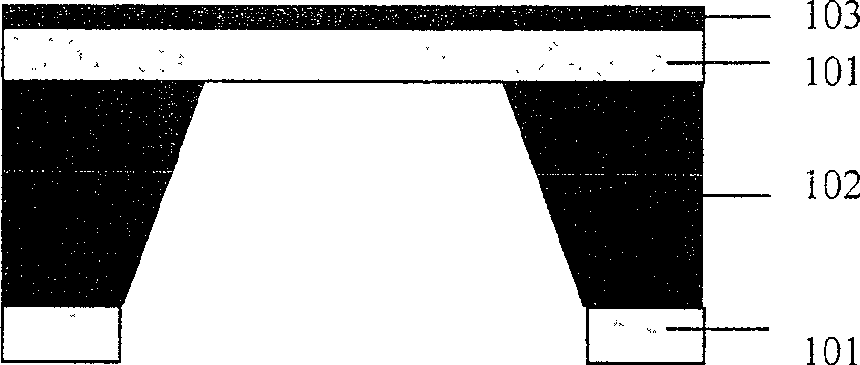

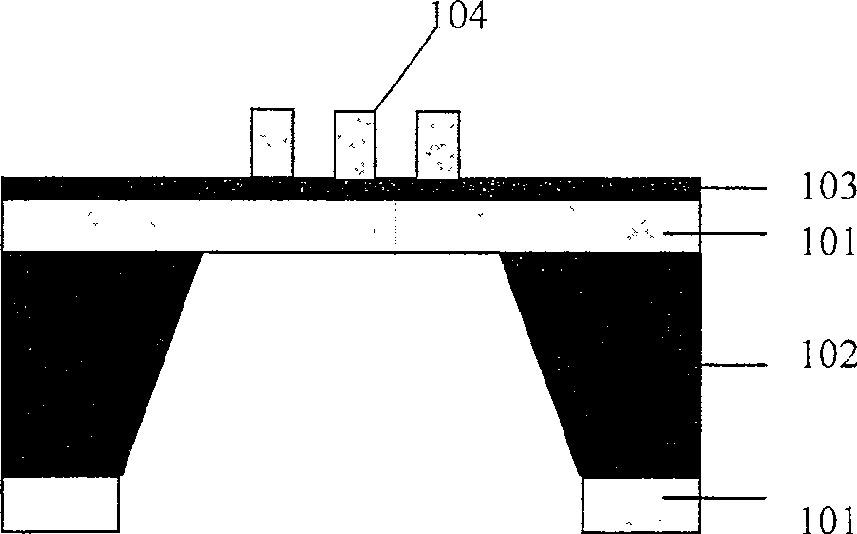

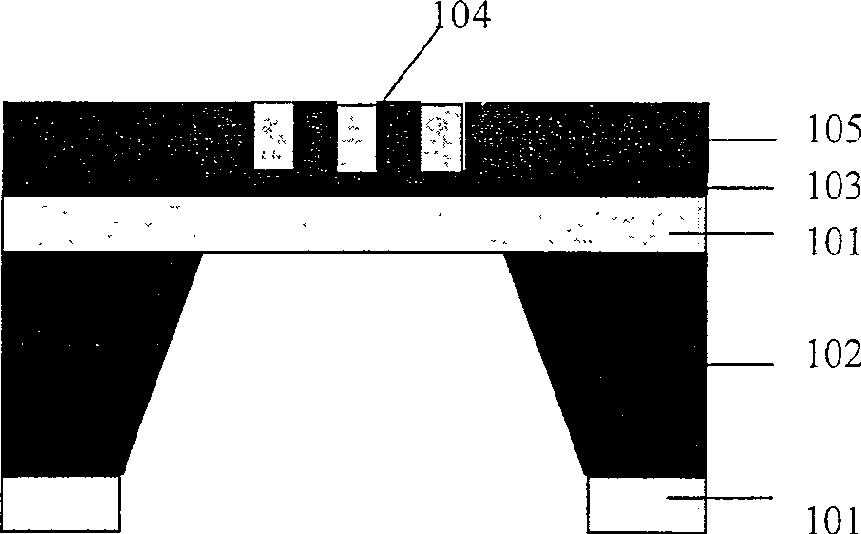

[0035] Black used in the drawings indicates opaque portions, and gray indicates translucent portions. It conforms to the usual representation method in the field of microelectronics technology.

[0036] 1. If Picture 1-1 As shown, a thin chromium and thin gold layer 103 is deposited on the self-supporting X-ray mask substrates 101 and 102 as an electroplating substrate; the thickness of the thin chromium and thin gold film 103 is 10 to 30 nm, and is obtained by electron beam evaporation. of;

[0037] 2. If Figure 1-2 As shown, an electron beam photoresist is cast on the surface of the thin chromium and thin gold layer 103, and electron beam lithography is performed to obtain a high-resolution grating pattern 104;

[0038] 3. If Figure 1-3 As shown, the grating pattern 104 is used as an electroplating mold, and the sheet is placed in a gold electroplating solution to electroplate an X-ray mask absorber gold pattern 105;

[0039] 4. If Figure 1-4 As shown, the electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com