Process of utilizing afterheat of casting in reducing stress ageing treatment

A residual stress and aging treatment technology, used in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of difficult processing, increased tool wear, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

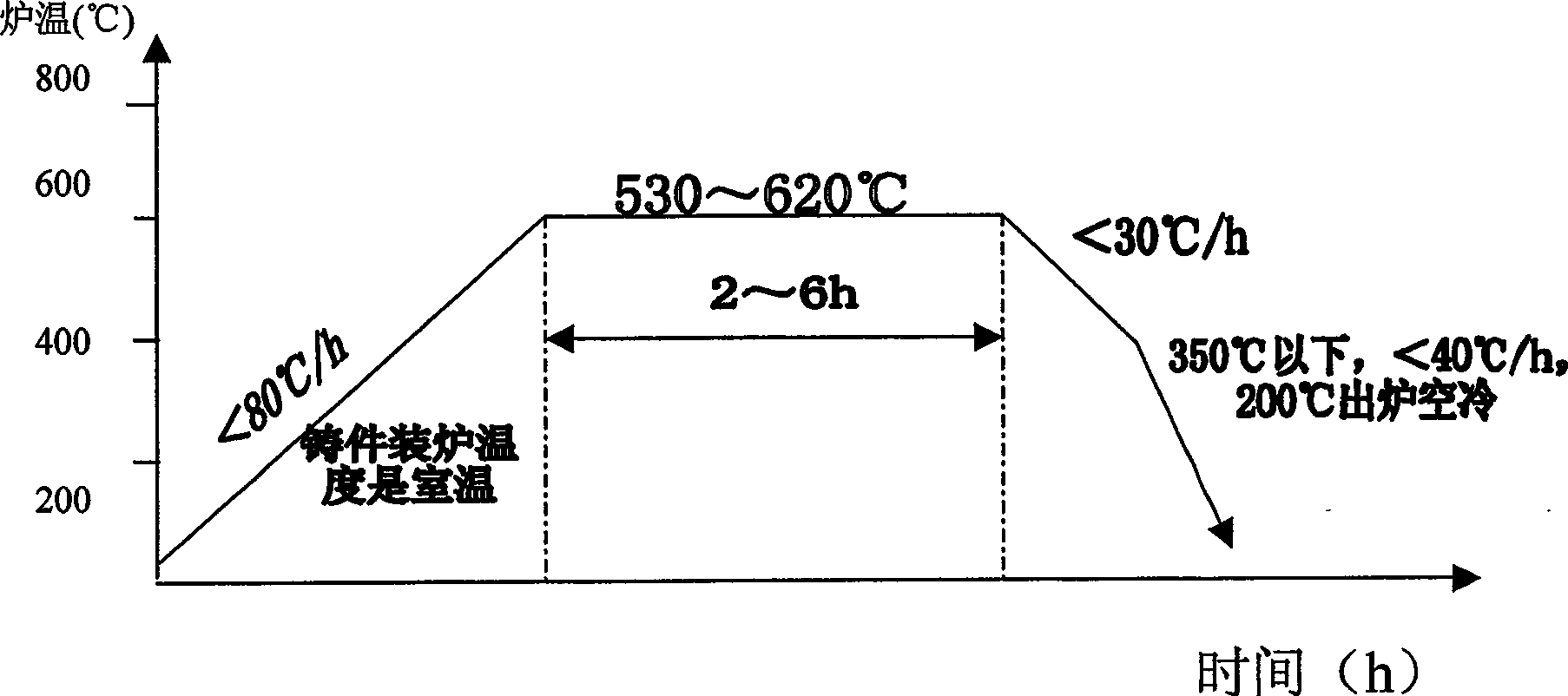

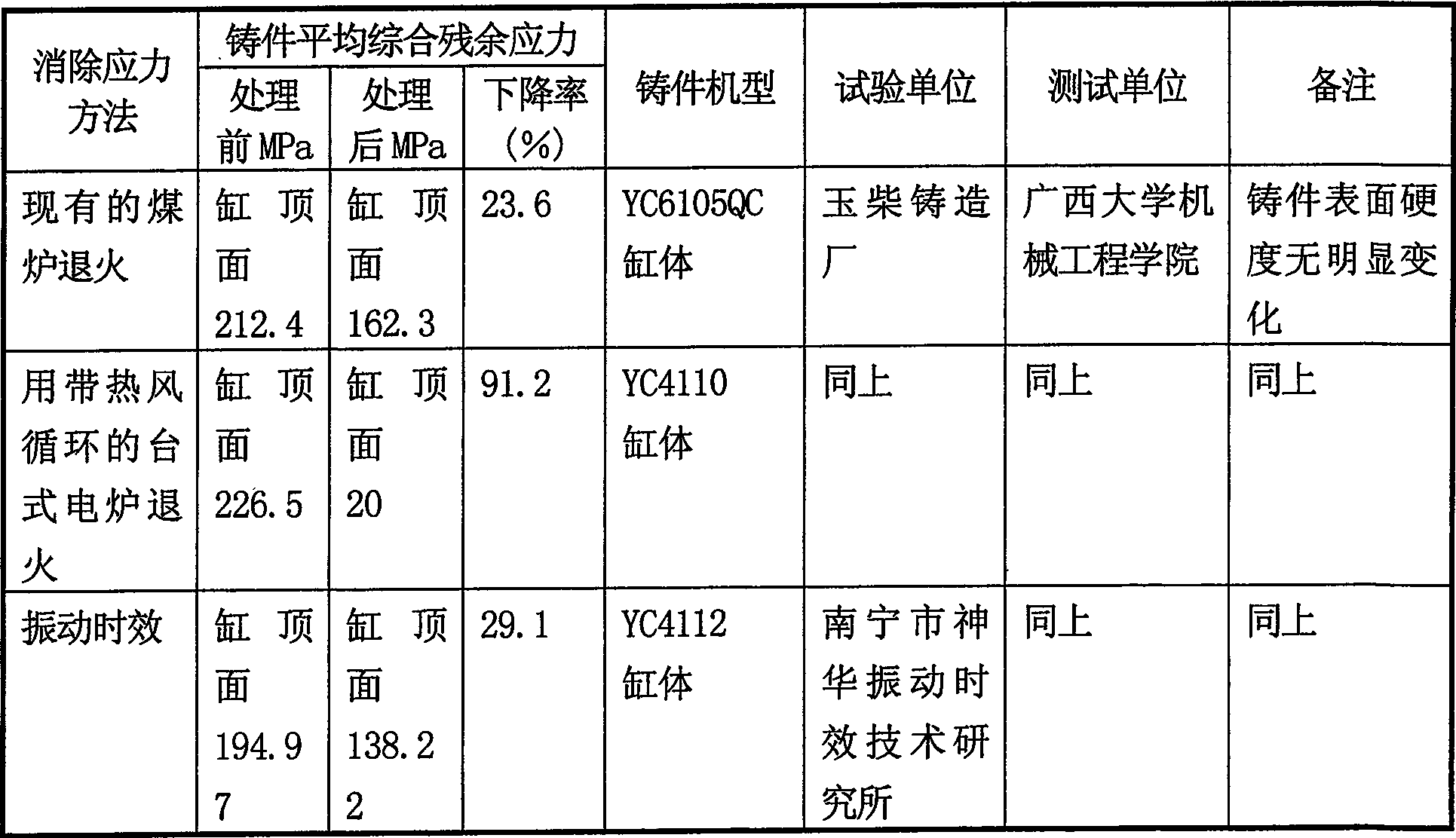

[0079]Castings are unpacked at 300-800°C, pushed to the vibrating shakeout machine, the manipulator removes the pouring riser, removes most of the molding sand and core sand, puts the castings into the continuous annealing furnace, and continuously heats up to 450-650°C in the heating section After heat preservation for 1 to 8 hours, slowly cool in the cooling section to below 200°C, take out the furnace and air cool to room temperature. After testing, the casting residual stress of the casting is less than 60MPa, and the energy consumption per ton is about 1 / 4 of that of the commonly used traditional stress-reducing treatment process, which saves energy, reduces production costs and improves production efficiency. Use the manipulator to pick up or put down the casting, clean the sand, and remove the riser. The action program of the manipulator is designed according to the purpose, and the corresponding mechanical parts and electronic circuit boards are configured according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com