A kind of cast iron with high dimensional stability and preparation method thereof

A dimensional stability, cast iron technology, applied in the field of high strength, high elastic modulus, high dimensional stability, low stress cast iron, can solve the problem of not meeting the performance requirements of HT300, increasing the casting stress of castings, reducing the mechanical properties of materials, etc. Problems, to achieve good retention, reduce casting residual stress, good hardness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

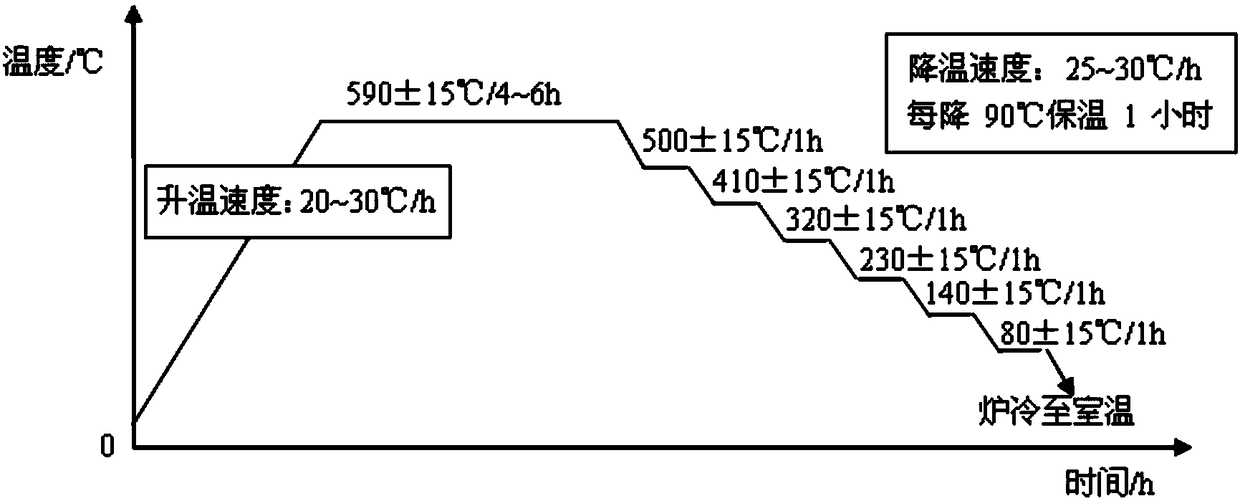

[0038] Casting production method of high dimensional stability cast iron castings:

[0039] The melting of molten iron adopts medium frequency induction furnace and neutral lining. The amount of steel scrap added is 70% (weight percentage, the same below), the amount of pig iron added is 5%, the amount of returned charge is 21%, other alloys and recarburizers are the balance, and the chemical composition of molten iron meets the technical requirements. Liquid iron superheat temperature: 1504 ℃. The inoculation treatment is carried out by "incubation method incubating in the bag + inoculation in the tap tank + inoculation with flow". The inoculant is FeSi75, and the addition amount is 0.6% of the weight of the molten iron after deployment. The inoculated molten iron is poured into resin sand casting Type, the castings are cooled to 180 ℃, boxed, cleaned and then heat treated.

[0040] The main chemical composition (mass fraction, %) of the casting is: C 3.21%, Si 2.09%, Mn 1....

Embodiment 2

[0044] Example 2 is basically the same as Example 1, except that the main difference is that the addition of steel scrap is 75%, the addition of pig iron is 8%, the addition of returned material is 13%, and other alloys and recarburizers are the balance. The agent is a high-calcium barium inoculant, and the amount of the inoculant added is 0.68% of the weight of the molten iron after deployment; the superheating temperature of the molten iron: 1540°C; the heat treatment time of the casting at 590±15°C is 6 hours.

[0045] The main chemical composition (mass fraction, %) of the casting is: 3.17%C, 1.89%Si, 0.95%Mn, 0.042%P, 0.036%S, 0.28%Cr, 0.69%Cu, 3.81%CE.

[0046] The test results of the casting are: tensile strength: 343 (MPa), modulus of elasticity: 135 (GMPa), hardness 218HBW, residual stress of the casting: 23.4 (MPa).

Embodiment 3

[0048] Example 3 is basically the same as Example 1, except that the main difference is that the addition of steel scrap is 65%, the addition of pig iron is 7%, the addition of recycle material is 24%, and the balance of other alloys and recarburizers, inoculation The agent is a high-calcium barium inoculant, and the amount of the inoculant added is 0.7% of the weight of the molten iron after deployment; the superheating temperature of the molten iron: 1520°C; the heat treatment time of the casting at 590±15°C is 6 hours.

[0049] The main chemical composition (mass fraction, %) of the casting is: 3.19%C, 1.96%Si, 1.10%Mn, 0.058%P, 0.031%S, 0.34%Cr, 0.56%Cu, 3.86%CE.

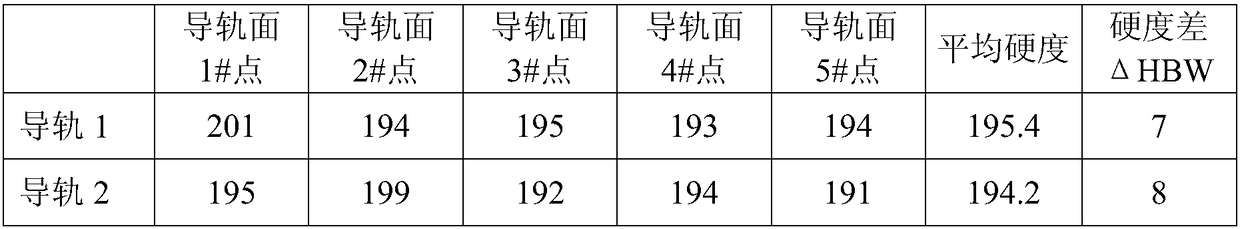

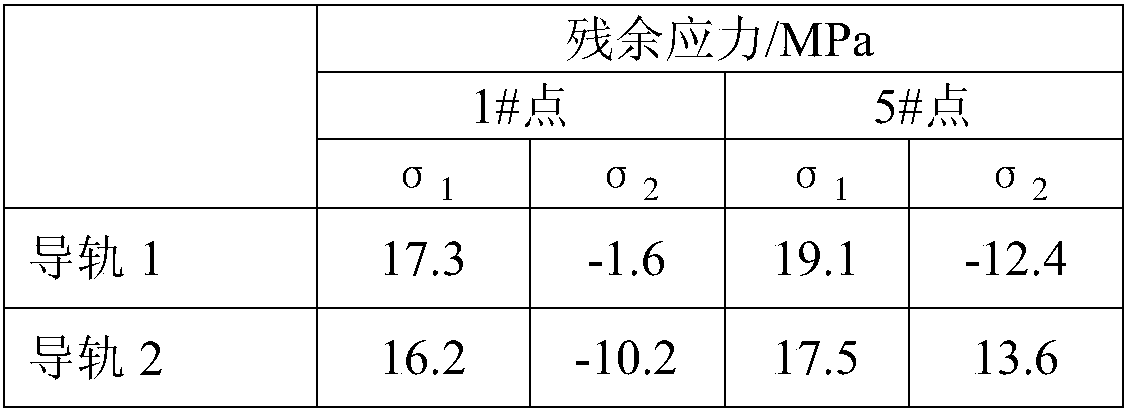

[0050] The product is a machine bed, and the test results of the bed casting are: tensile strength: 338 (MPa), modulus of elasticity: 131 (GMPa), residual stress of the casting: 16.2 (MPa). Table 1 shows the hardness of the rail surface of the cast iron bed with high dimensional stability produced by the technol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com