A precision casting method for a solid duplex single crystal guide vane

A technology of guide vane and precision casting, which is applied in the precision casting field of solid duplex single crystal guide vanes, can solve the problems of large volume, miscellaneous crystals, looseness, recrystallization, complex structure of double guide vanes, etc., and achieves dimensional consistency Good, improve the development efficiency, avoid the effect of the formation of recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the purpose, technical solutions and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

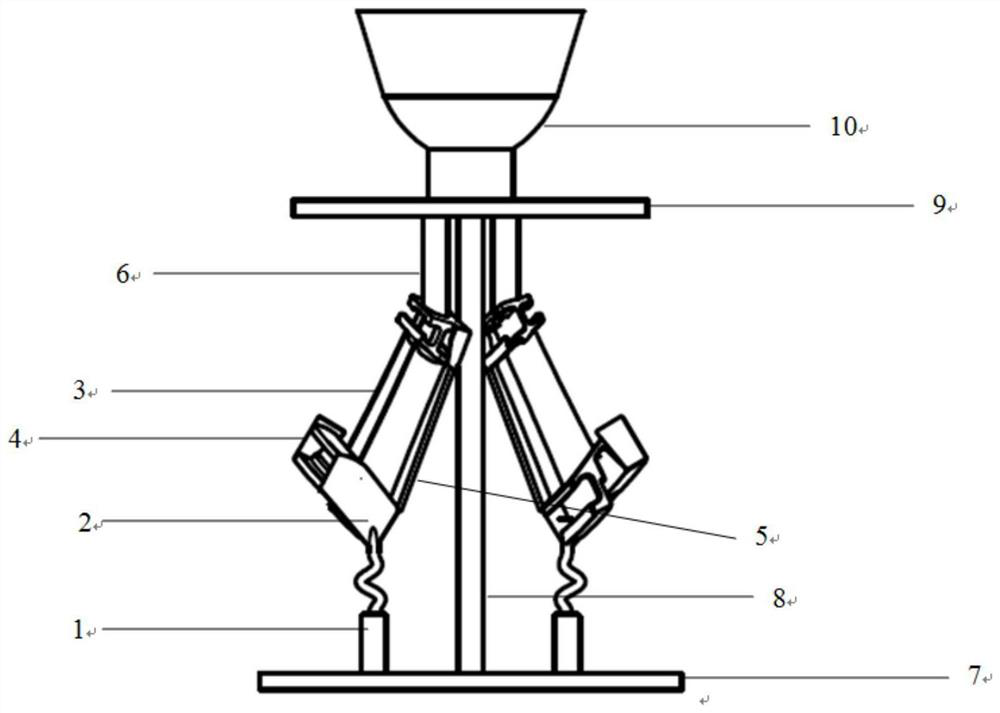

[0020] The solid duplex single-crystal guide vane has a complex structure and large volume, has the upper and lower double-edge plate structure, and has the characteristics of large span and narrow space between duplex blade blades. It is easy to cause miscellaneous crystals, looseness, and recrystallization during the preparation process. and other metallurgical defects, in order to solve the metallurgical problems in the preparation process of solid double single crystal guide vanes and meet the needs of high performance aeroengines for double single crystal guide vanes, the present invention proposes a precision casting of solid double single crystal guide vanes method.

[0021] Specifically, in the method of the present invention, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com