Energy-storage device, package structure of energy-storage device and method for fabrication thereof

A technology for energy storage devices and packaging structures, applied in structural parts, lamination devices, chemical instruments and methods, etc., can solve the problems of difficult sealing, difficult use of metal cans, lack of changes in appearance, etc., and achieves high flexibility, High water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the purpose, structure, features, and functions of the present invention, the detailed description of the accompanying examples is as follows. The above descriptions about the content of the present invention and the following descriptions of the embodiments are used to demonstrate and explain the principle of the present invention, and to provide further explanation of the patent application scope of the present invention.

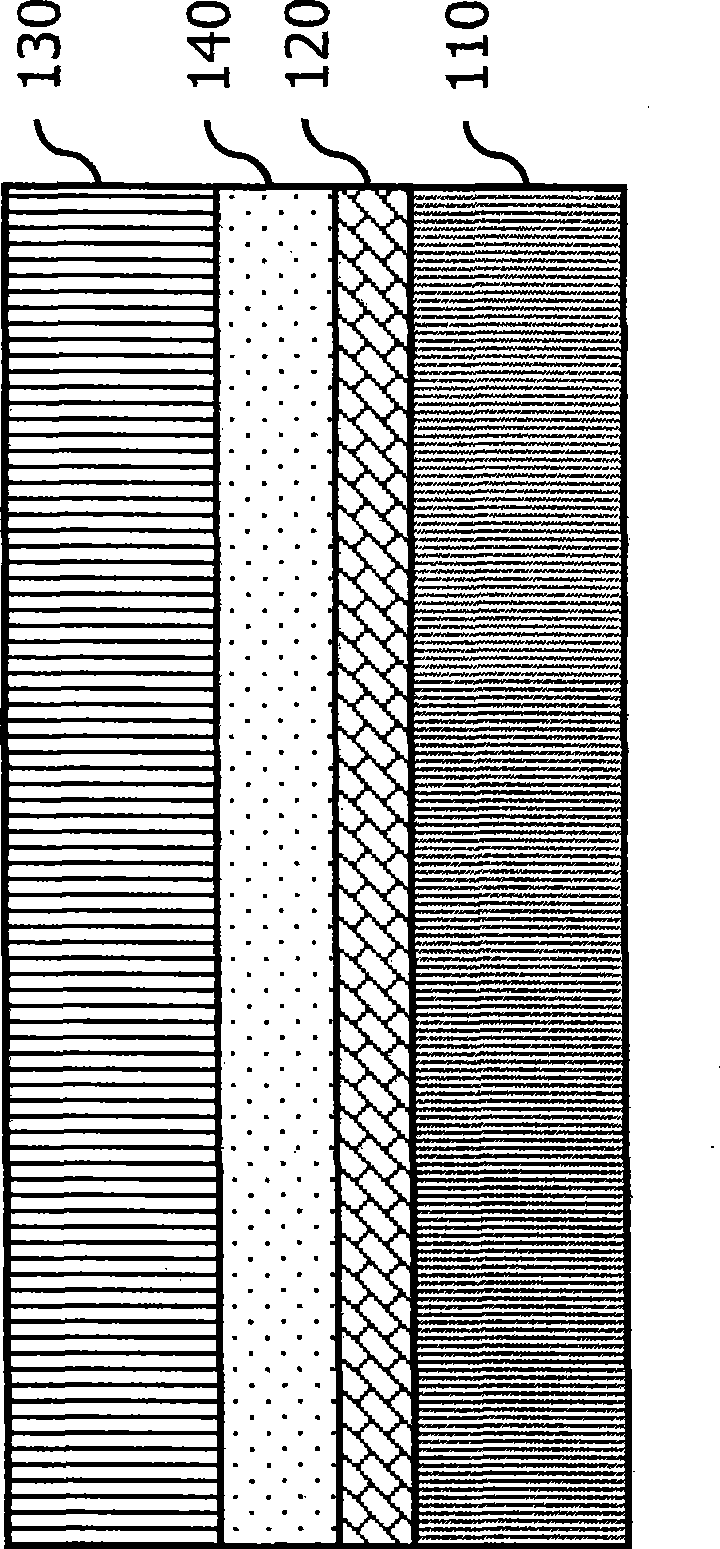

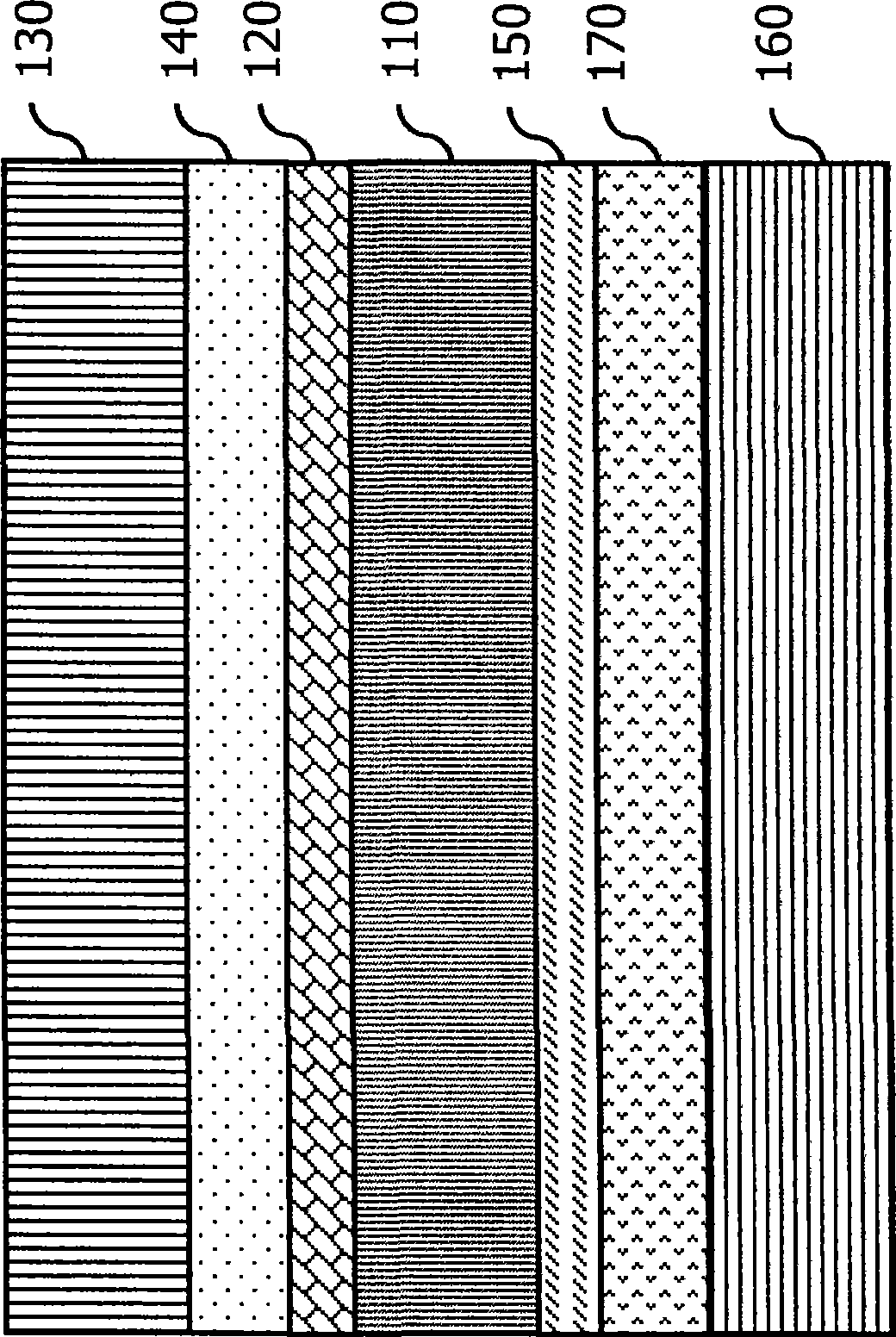

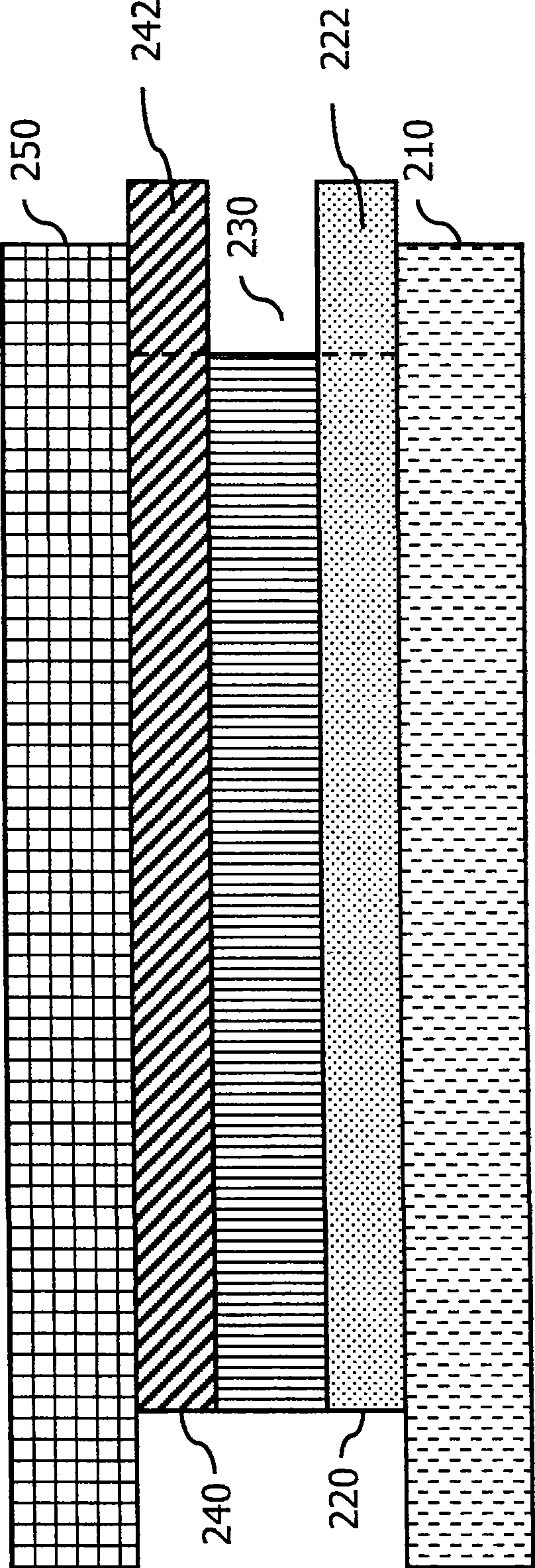

[0035] Please refer to Figure 1A , is a schematic diagram of the packaging structure of the energy storage device of the present invention, which can be applied to the outer packaging shells of secondary batteries, fuel cells, and capacitors. The thickness of the overall structure ranges from 10 μm to 50 μm, and at least includes a first polymer layer 110, a first metal layer 120, and a second polymer layer 130, wherein the first metal layer 120 is electroplated on one side of the first polymer layer 110 by an electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com