Production method of extracellular matrix engineered catheter containing olfactory ensheathing cells

A tissue engineering scaffold and olfactory ensheathing cell technology, which is applied in the field of extracellular matrix tissue engineering scaffold production, can solve the problems of poor histocompatibility, insignificant "bridge" formation, difficult source of seed cells, etc. Effects of stabilizing biological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

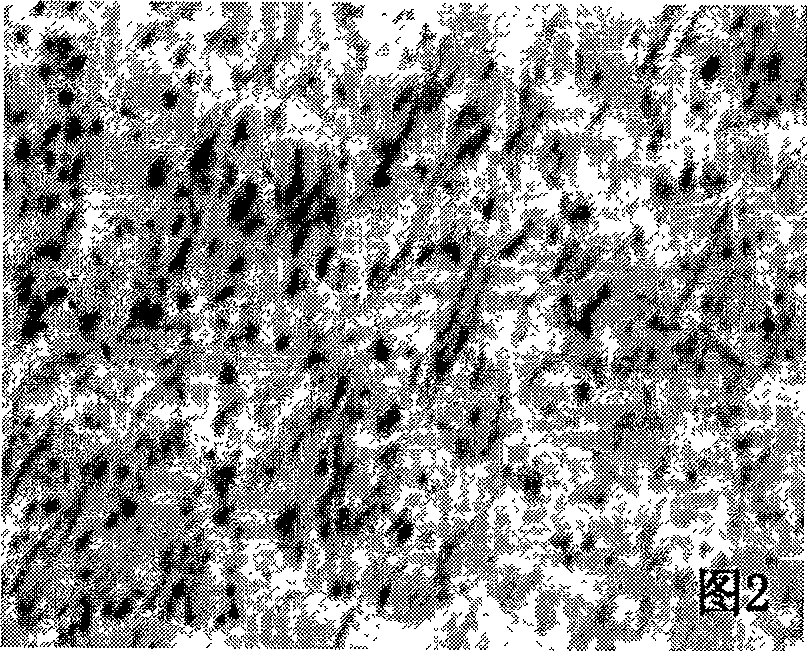

[0028] (1) In vitro culture and purification of olfactory ensheathing cells

[0029] The olfactory area of the nasal mucosa of self-cleaning adult SD rats was isolated and the olfactory mucosa was cut to make a cell suspension. The above cells were cultured by conventional cell culture methods, and the olfactory ensheathing cells were purified by subculture.

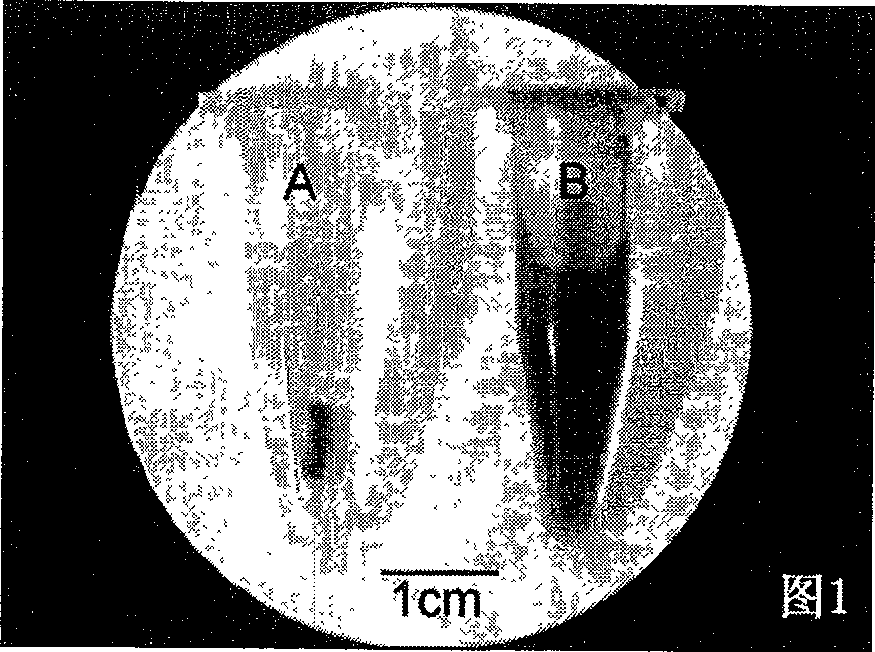

[0030] (2) Fabrication of tissue engineering scaffolds and planting of seed cells (olfactory ensheathing cells)

[0031] ① Fabrication of bracket

[0032] Dissolve laminin (final concentration: 10 μg / ml), fibronectin (final concentration: 10 μg / ml) and fibrinogen (final concentration: 100 mg / ml) in common F12 medium containing fetal bovine serum The outer matrix material is made into a compound jelly solution, and then fresh rat plasma is added at a volume ratio of the jelly solution to fresh rat plasma of 20:1, and the jelly solution is immediately sucked into a glass tube with a diameter of 3mm In a few minutes, th...

Embodiment 2

[0040] (1) In vitro culture and purification of olfactory ensheathing cells

[0041] The olfactory area of the nasal mucosa of self-cleaning adult SD rats was isolated and the olfactory mucosa was cut to make a cell suspension. The above cells were cultured by conventional cell culture methods, and the olfactory ensheathing cells were purified by subculture.

[0042] (2) Fabrication of tissue engineering scaffolds and planting of seed cells (olfactory ensheathing cells)

[0043] ① Fabrication of bracket

[0044] Dissolve laminin (final concentration: 15 μg / ml), fibronectin (final concentration: 15 μg / ml) and fibrinogen (final concentration: 150 mg / ml) with common F12 medium containing fetal bovine serum The outer matrix material is made into a compound jelly solution, and then fresh rat plasma is added at a volume ratio of 15:1 between the jelly solution and fresh rat plasma, and the jelly solution is immediately sucked into a glass tube with a diameter of 5 mm In a few mi...

Embodiment 3

[0051] (1) In vitro culture and purification of olfactory ensheathing cells

[0052] The olfactory area of the nasal mucosa of self-cleaning adult SD rats was isolated and the olfactory mucosa was cut to make a cell suspension. The above cells were cultured by conventional cell culture methods, and the olfactory ensheathing cells were purified by subculture.

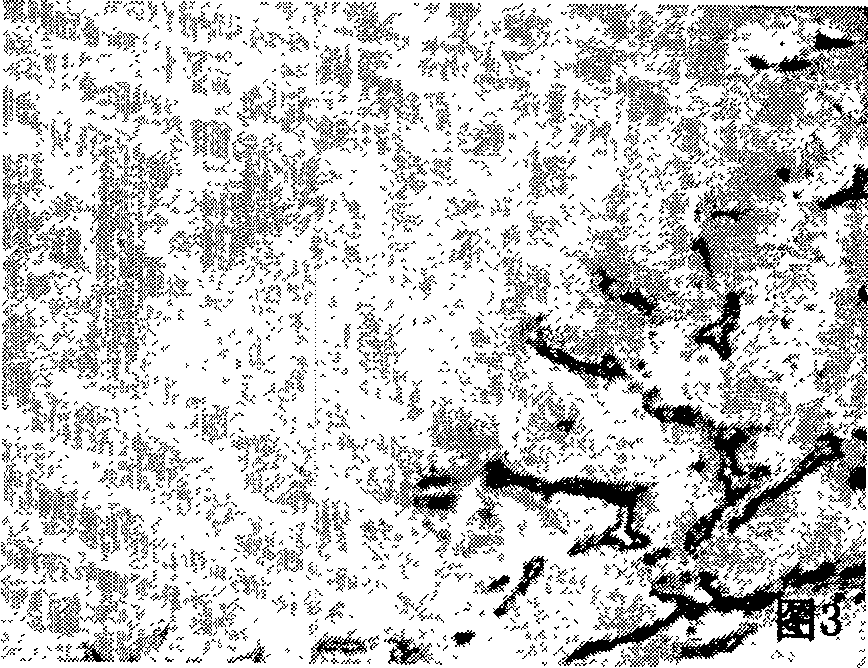

[0053] (2) Fabrication of tissue engineering scaffolds and planting of seed cells (olfactory ensheathing cells)

[0054] Dissolve laminin (final concentration of 20 μg / ml), fibronectin (final concentration of 20 μg / ml) and fibrinogen (final concentration of 200 mg / ml) in common F12 medium containing fetal bovine serum The outer matrix material is made into a compound jelly solution, and then fresh rat plasma is added at a ratio of 10:1 between the jelly solution and fresh rat plasma, and 200 μl of the jelly solution is dropped into the 24-well culture plate. Then add 20 μl of fresh rat plasma into the hole with the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com