Production of white cerium oxide

A cerium oxide and white technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve problems such as complex process, high product cost, and large pollution impact, and achieve simple process, low cost, and small environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

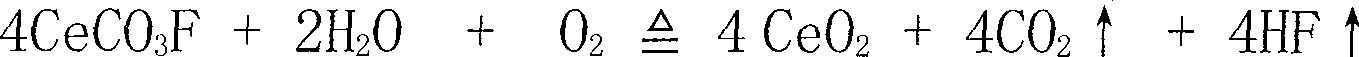

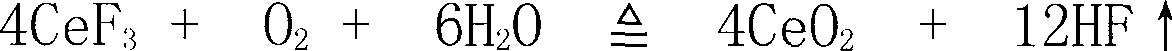

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Get 100g of cerium carbonate, add water to adjust slurry. Slowly add 7g of hydrofluoric acid (40%) under stirring state, fully react for 30 minutes, filter and dry the slurry. Then it is divided into four parts and fired at 800°C, 850°C, 900°C, and 950°C for 3 hours respectively, and the baked products are naturally cooled to room temperature to obtain white cerium oxide products.

[0016] The raw material used here is cerium carbonate with the following characteristics:

[0017] TREO 44%~50%

[0018] CeO 2 / TREO>99.9%

[0019] The roasted product, that is, the white cerium oxide product, was tested and analyzed, and the results are shown in Table 1.

[0020] Table 1

[0021]

Embodiment 2

[0022] Embodiment 2: Take 5 parts of cerium carbonate, each 100g, add water respectively to make slurry. Then slowly add 3g, 7g, 10g, 13g, 16g of hydrofluoric acid (40%) under stirring state, fully react for 30 minutes, filter and dry the slurry. Then calcined at 900° C. for 3 hours each, and the calcined product was naturally cooled to room temperature to obtain a white cerium oxide product.

[0023] The roasted product was tested and analyzed, and the results are shown in Table 2.

[0024] Table 2

[0025]

Embodiment 3

[0026] Embodiment 3: get cerium chloride (TREO 45%, CeO 2 / TREO 99.9%) 500g water to make an aqueous solution, add 35g hydrofluoric acid (40%) under stirring, after fully reacting for 30 minutes, add ammonium bicarbonate until there is no rare earth in the supernatant, filter the slurry , wash, dry. Then divide the raw materials prepared by the above method into 5 parts, and roast them at 800°C, 850°C, 900°C, and 950°C for 3 hours respectively, and cool the calcined products to room temperature naturally.

[0027] The roasted product was tested and analyzed, and the results are shown in Table 3.

[0028] table 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com