Ink coating composition and curing method therefor, optical glass fiber and ribbon assembly

A technology of coating composition and glass fiber, which is applied in cladding optical fiber, ink, coating, etc., can solve the problem of expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

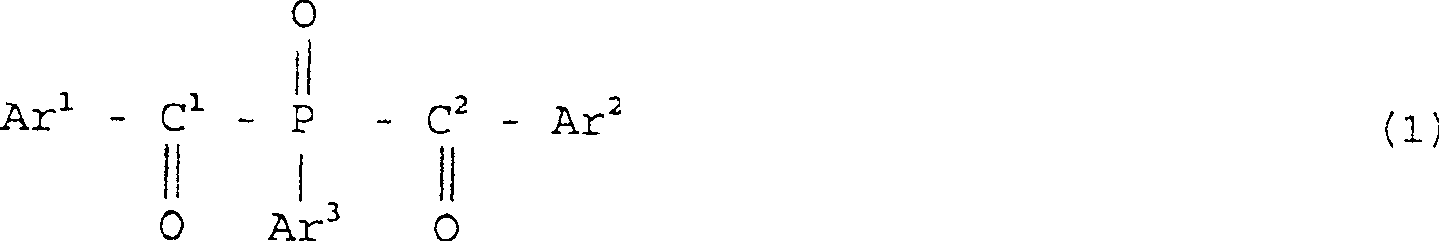

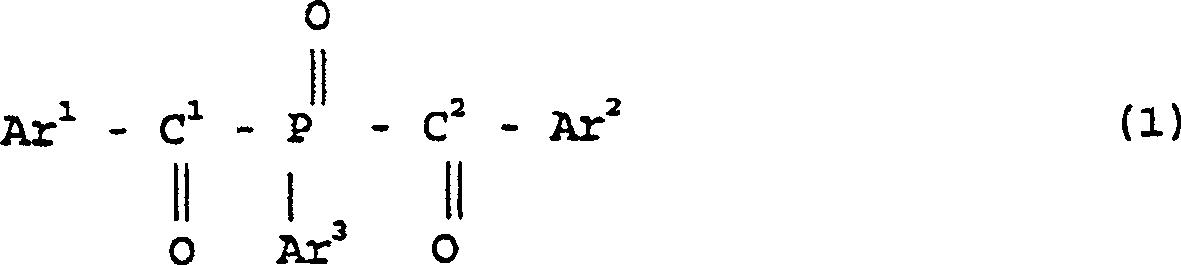

Image

Examples

Embodiment I

[0162] A radiation curable base composition was first formed by mixing the various components shown in Table 1 .

[0163] Table 1

[0164] components Amount (% by weight of total composition) Ethoxy diacrylate monomer 1 42.85 Aliphatic Urethane Diacrylate Oligomer 2 25.25 pentaerythritol tetraacrylate 12.55 1,6-Hexanediol diacrylate 1.68 Isobornyl Acrylate 3.88 Phenoxyethyl acrylate 3.88 Butylated hydroxytoluene 0.52 Benzophenone 8.33 2-Methyl-1-(4-(methylthio)-phenyl)-2-(4-morpholinyl)-1-propanone 1.04

[0165] 1 CN120, (Sartomer)

[0166] 2 Ebecryl 264, (Radcure)

[0167] 96% of this base composition was then mixed with 4% of CGI 819 (Ciba Geigy) to form a radiation curable composition. 88% by weight of the radiation curable composition was mixed with 9% by weight of blue pigment, 3% by weight of white pigment to form a radiation curable ink composition.

[0168] A 20 μm thick drawdown film of the in...

Embodiment II and III, and comparative Embodiment A

[0178] Two radiation curable carrier systems were first formed by mixing the various components shown in Tables 2 and 3.

[0179] Table 2

[0180] carrier system AA

[0181] components Amount (% of total system weight) Ethoxyacrylate Monomer 33.9 Aliphatic Urethane Diacrylate Oligomer 19.9 pentaerythritol tetraacrylate 9.95 Isobornyl Acrylate 3.06 Phenoxyethyl acrylate 3.06 1,6-Hexanediol diacrylate 13.64 Silicone diacrylate 1.14 2,6-di-tert-butyl-methyl-phenol 0.57 2-Methyl-1-(4-(methylthio)phenyl)-2-(4-morpholinyl)-1-propanone 4.55 Improve ink curing speed photoinitiator CGI819 1.14 Acrylated benzophenone 9.09

[0182] table 3

[0183] Carrier system BB

[0184] components Amount (% of total system weight) Ethoxyacrylate Monomer 35.93 Aliphatic Urethane Diacrylate Oligomer 21.14 pentaerythritol tetraacrylate 10.55 Isobornyl Acrylate 3.24 Phenoxyethyl acr...

Embodiment IV

[0192] Ink coating compositions were prepared by mixing the following components:

[0193] Component % (by weight of the total composition)

[0194] Ebecryl 3700 (ethoxy acrylate) 51.0

[0195] Alkoxylated aliphatic diacrylate 30.0

[0196] Irgacure 819 1 1.0

[0197] Irgacure 907 3.0

[0198] Benzophenone 4.0

[0199] Blue Pigment (Penn Color) 1.5

[0200] BYK 333 2 0.5

[0201] 1 Irgacure 819 by Ciba Geigy

[0202] 2 BYK 333 is a polyether-modified dimethyl polysiloxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com