Diode string structure

A diode string and diode technology, applied in the field of diode string structure, can solve the problems of affecting the normal operation of the circuit, affecting the response speed of high-speed circuits, and large structure area, and achieve the effects of small leakage current, small parasitic capacitance, and small structure area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

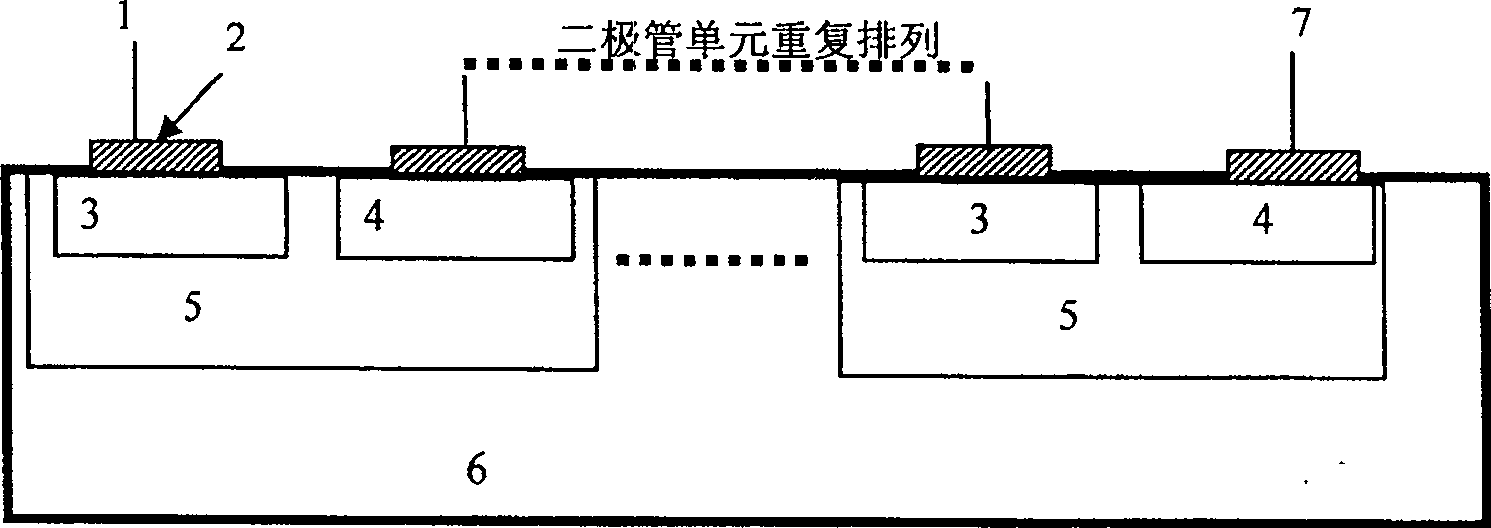

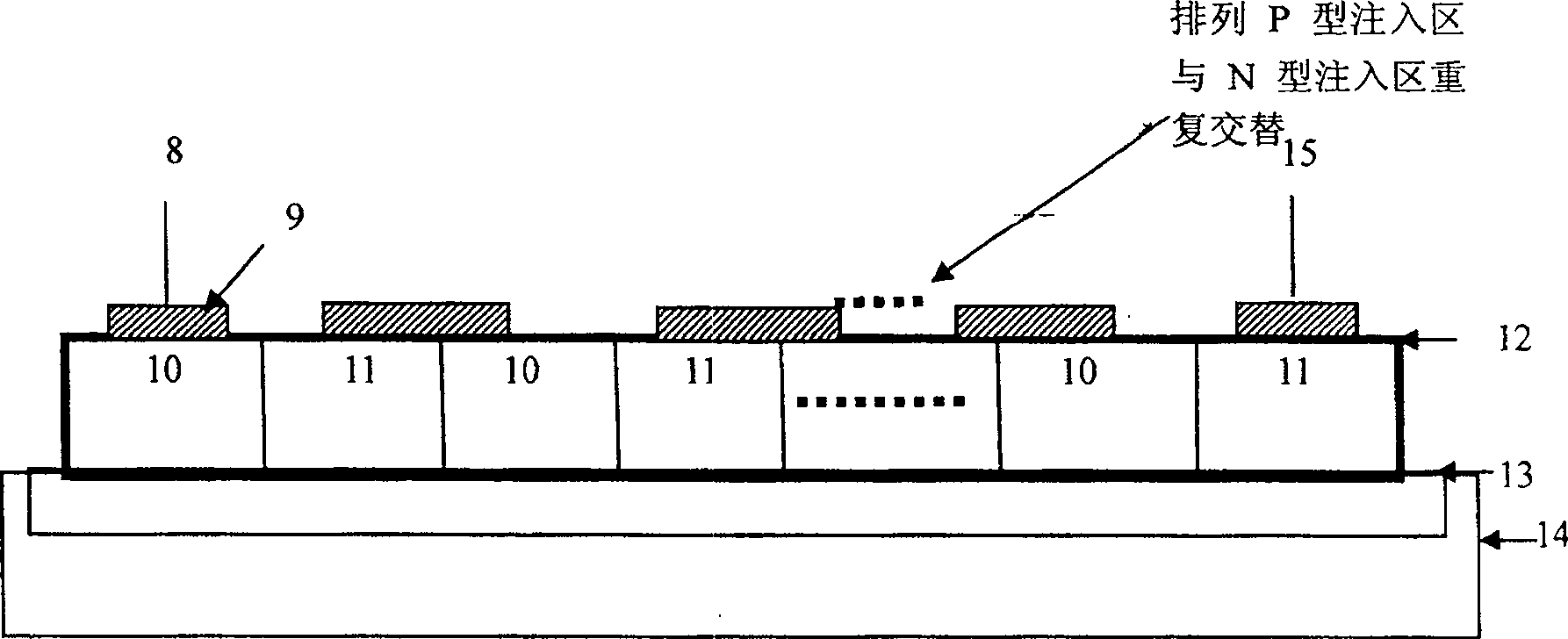

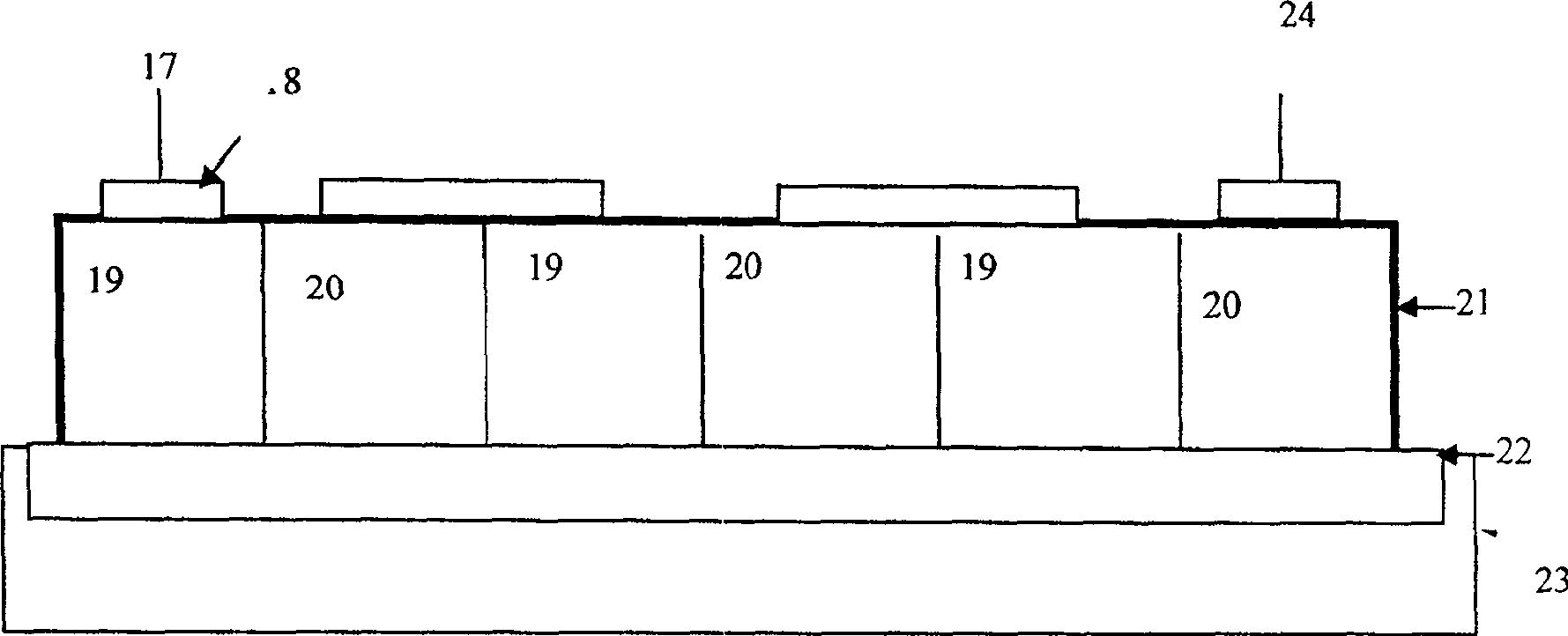

[0016] Such as image 3 As shown, it is a schematic cross-sectional view of a specific embodiment of the present invention. In this embodiment, three diode units form a diode string, wherein: 17, anode, 18, metal polysilicon, 19, P-type implantation region, 20, N-type Implantation area, 21, polysilicon, 22, field oxidation insulating layer, 23, silicon substrate, 24, cathode; Figure 4 yes image 3 The schematic diagram of the equivalent circuit. In the implementation, polysilicon in the existing CMOS process is used as the carrier of the three diodes shown in the figure, and three PN junctions are formed on the polysilicon by implanting different impurities, and the P-type implanted regions of two adjacent diode units are connected to the N-type The sides of the injection regions are connected and alternately arranged in a string, and the N-type injection regions and P-type injection regions of adjacent diode units are connected by metal oxide silicide of CMOS technology, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com