Method for mixing jatropha oil and petroleum diesel oil as diesel fuel

A petrochemical diesel and diesel engine technology, applied in the fuel, petroleum industry, liquid carbon-containing fuel and other directions, can solve problems such as increasing cost, and achieve the effects of improving low temperature performance, good safety and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

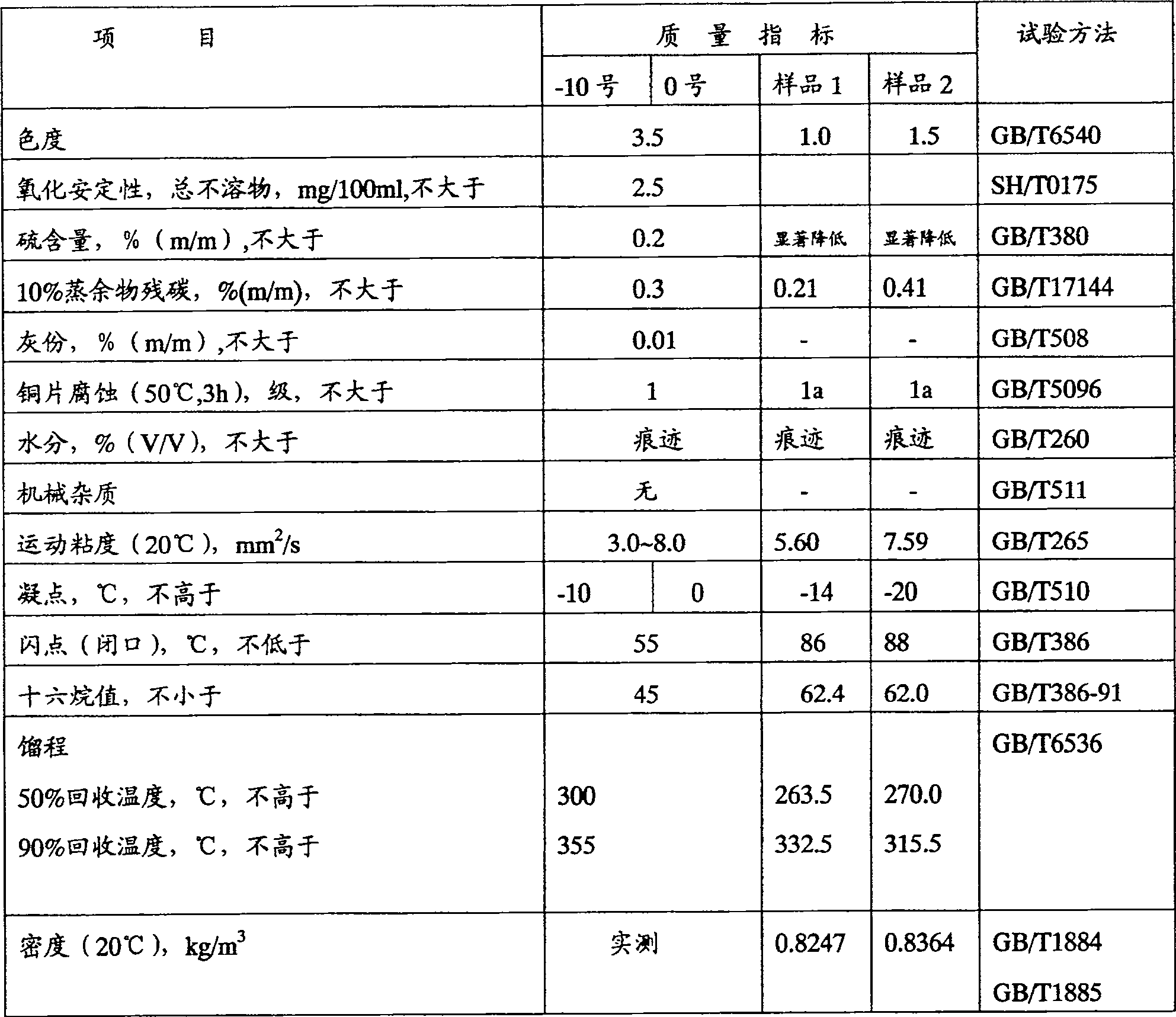

[0021] Example 1: The refined oil of tung tree is provided by Bioresource Innovation Company of Yuanyang County, Yunnan, and its linoleic acid content is greater than 30%. The production place of tung tree seeds is Nansha Town, Yuanyang County.

[0022] The above-mentioned tung tree seed refined oil was blended with No. 0 diesel oil, the former accounted for 20% of the total weight of the mixture, and the blended fuel oil 1 was obtained.

[0023] The above-mentioned tung tree seed refined oil was blended with No. 0 diesel oil, and the former accounted for 30% of the total weight of the mixture to obtain the blended fuel oil 2.

[0024] As a comparative test: No. 0 diesel oil, blended fuel 1, and blended fuel 2 are used as fuel for the diesel engine to run. The diesel engine model is 4100QBZ, the atmospheric temperature is 20-27°C, the atmospheric pressure is 936-950Pa, and the relative humidity is 70-90%.

[0025] The results show that the blended fuel 1 and blended fuel 2 ca...

Embodiment 2

[0027] Embodiment 2: The difference with embodiment 1 is that the refined oil of tung tree seeds accounts for 48% of the total weight of the blended fuel. Compared with No. 0 diesel oil, the average power of the engine is reduced by 5.8%, and other performance indicators are basically the same. This blended fuel can be used as fuel for agricultural tractors and the like.

Embodiment 3

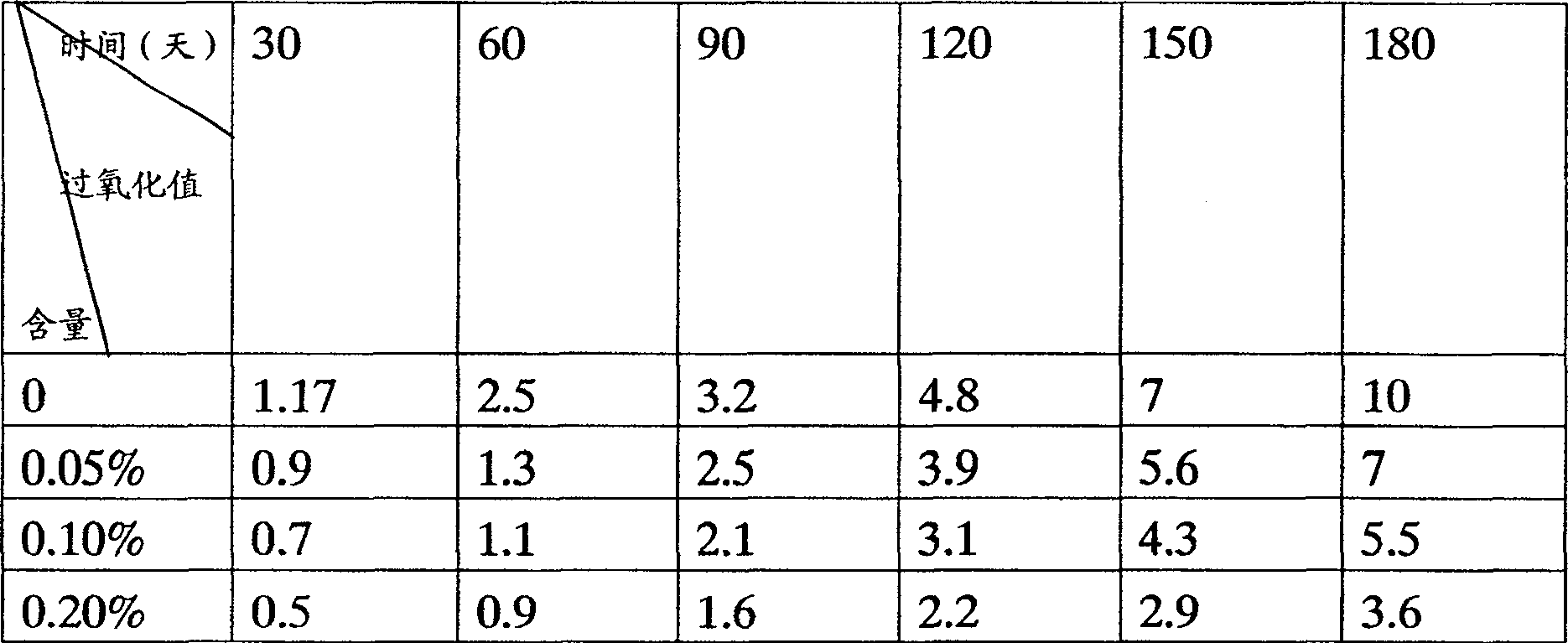

[0028] Embodiment 3: The refined oil of tung tree seeds is blended with No. 0 diesel oil, and the former accounts for 50% of the total weight of the fuel mixture. Add different contents of commercially available rosemary extracts to the fuel mixture and measure the peroxide value of the fuel mixture rich in linoleic acid in different periods, measure 3 times in parallel, and do a control test (without adding rosemary extract), and its arithmetic mean was taken as the result. The results are shown in the table below.

[0029] Peroxide value of fuel mixtures with different contents of rosemary extract

[0030]

[0031] Measurement times n=3

[0032] The results show that the ability of rosemary extract to slow down the oxidation of fuel mixture has a dose-effect relationship with the amount of addition. Rosemary extract has a good antioxidant effect on fuel mixture, can inhibit its decay, rancidity and reduce the generation of free radical peroxides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com