Method for manufacturing coaxial cable insulated layer and foam material and material processing technology

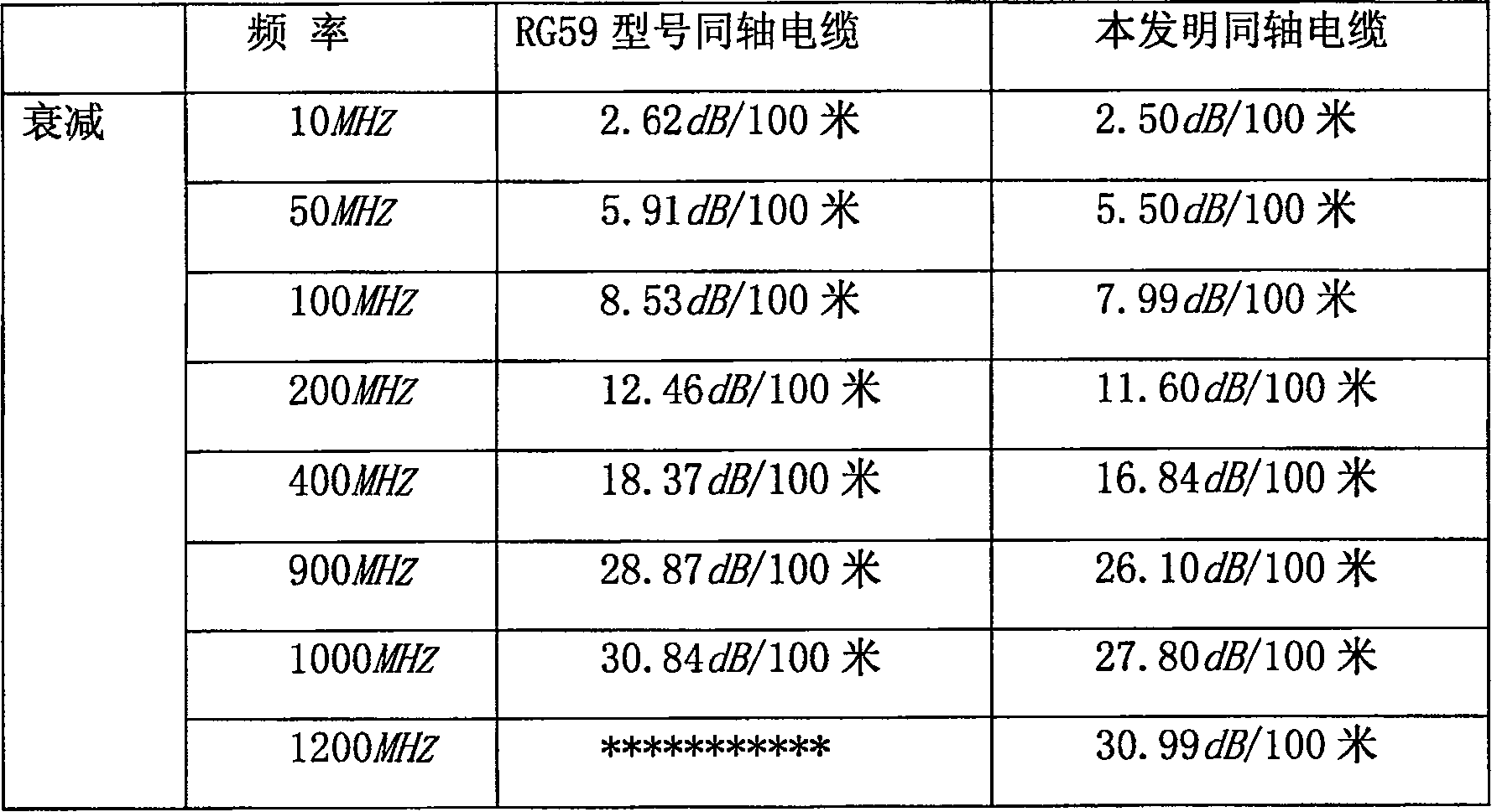

A coaxial cable and insulating layer technology, applied in the direction of conductor/cable insulation, etc., can solve the problems of reduced voltage standing wave performance, increased cable attenuation, unevenness, etc., to reduce voltage standing wave ratio, reduce signal attenuation, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw materials: 100 parts of FEP (capacity flow index MFI is 4) raw materials,

[0023] Nucleating agent masterbatch: 0.8 parts of boron fluoride (BF4) (nanomaterials below 0.09 microns);

Embodiment 2

[0025] Raw materials: 100 parts of FEP (capacity flow index MFI is 8) raw materials,

[0026] Nucleating agent masterbatch: 0.9 parts of silicon fluoride (SiF4) (nanomaterials below 0.07 microns);

[0027] Antioxidant: Antioxidant 1010 0.5 parts,

[0028] Anti-copper agent: 0.3 parts of OABH.

Embodiment 3

[0030] Raw materials: FEP (capacity flow index MFI is 6) pellets 100 parts,

[0031] Nucleating agent masterbatch: 0.3 parts of silicon nitride (SiN) (nanomaterials below 0.06 microns);

[0032] Anti-copper agent: 0.4 parts of OABH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com